el cheapo No. 4

need I go on ???

anyway. I am upping my game and either tuning up or replacing my cheap / diy tools.

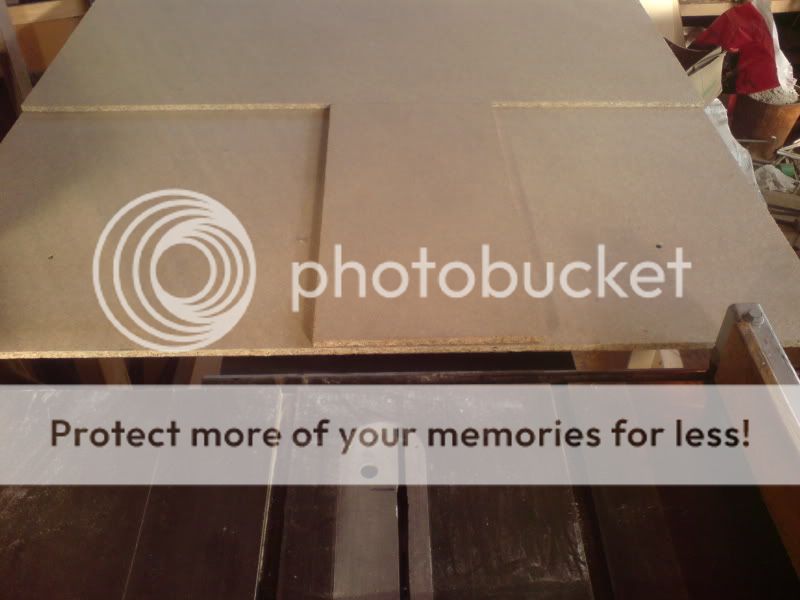

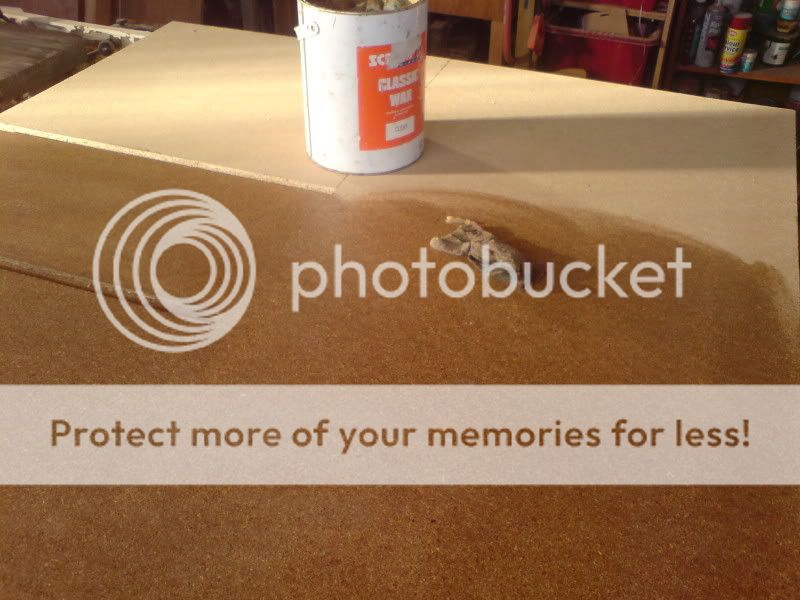

my hand plane removed wood - but never cut straight.

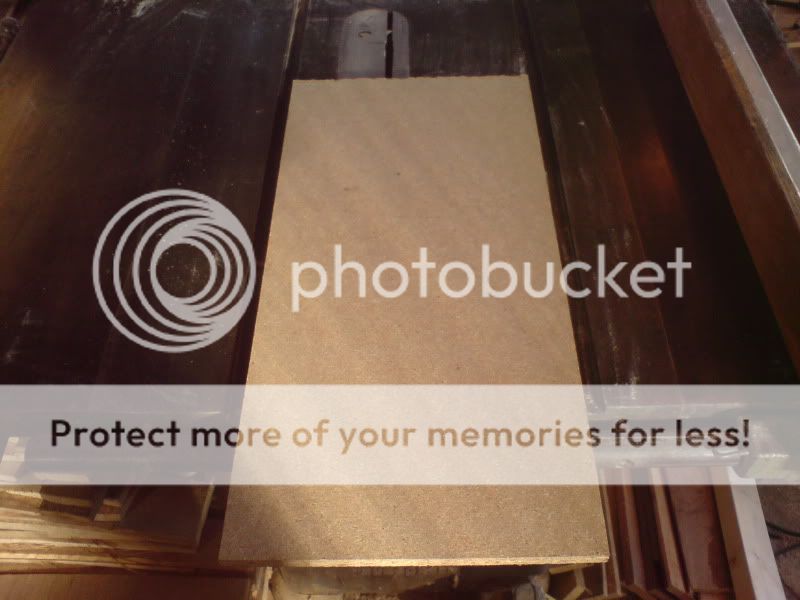

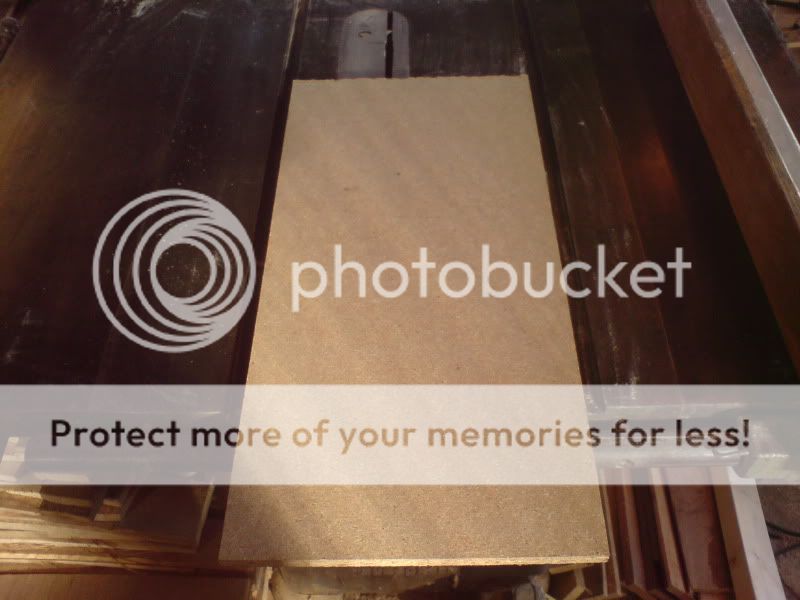

The blade wasn't square at the end - so I spent a bit of time flattening the back and squaring the bevel. on putting it back together - I noticed the whole lot is out of square

have a look and tell me if its junk

It was cheap - so no matter if its junk - I just dont want to waste my time trying to grind everything square, if its a lost cause.

any recomendation for an entry level plane ?

Ta

Rich

need I go on ???

anyway. I am upping my game and either tuning up or replacing my cheap / diy tools.

my hand plane removed wood - but never cut straight.

The blade wasn't square at the end - so I spent a bit of time flattening the back and squaring the bevel. on putting it back together - I noticed the whole lot is out of square

have a look and tell me if its junk

It was cheap - so no matter if its junk - I just dont want to waste my time trying to grind everything square, if its a lost cause.

any recomendation for an entry level plane ?

Ta

Rich