richarnold

Established Member

Hi Folks.

Just before Christmas I had an unexpected visitor drop by the house.

This was none other than new plane maker on the block, Ollie Sparks.

Ollie explained to me that he had been to see two of my oldest and dearest friends Bill And Sarah Carter, and they had asked him if he would mind dropping by with a small Christmas gift for me.

This was totally unexpected and left me very intrigued to say the least, but being a good boy I put the parcel under the tree ready for Christmas day.

Now anyone who has met Bill and Sarah will already know that you would be hard pressed to find anyone who is as kind, generous, and helpful in the hand tool world, But when I opened that parcel on Christmas morning I was knocked sideways.

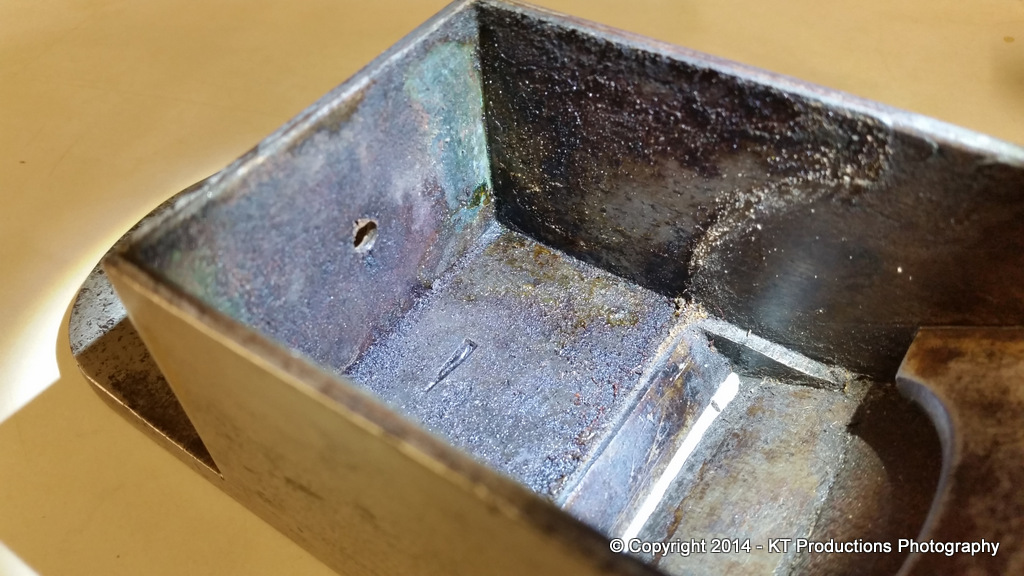

The first time I met Ollie Sparks, he showed me a plane that he had made that was a new prototype he was working on. Although he had been using it he said he was not happy with it and wanted to change some aspects of the design. For me it was love at first sight. Ollie felt it did not sit quite right in his hand, but to me it fitted like a glove.

At the recent MAC timbers open day I had another chance to handle the plane Of all the works of art on show that day this was the one I could not stop picking up and handling. The ever observant Bill must have noted my enthusiasm that day, and has somehow managed to get Ollie to part with this work of art, and in an immense act of generosity made me custodian of this little beauty.

I sometimes think it is a shame that planes such as these often end up in collectors cabinets, but be assured, this plane will from now on see lots of active duty, Just like my other plane by Bill that I have been using for more than 20 years

For those of you interested in the technical side of things the plane is 4 7/8" long with a 1 1/4" wide cutter.

[/URL

[/URL

[URL=http://s1263.photobucket.com/user/richarnold/media/003_zps8f7815d4.jpg.html]

Just before Christmas I had an unexpected visitor drop by the house.

This was none other than new plane maker on the block, Ollie Sparks.

Ollie explained to me that he had been to see two of my oldest and dearest friends Bill And Sarah Carter, and they had asked him if he would mind dropping by with a small Christmas gift for me.

This was totally unexpected and left me very intrigued to say the least, but being a good boy I put the parcel under the tree ready for Christmas day.

Now anyone who has met Bill and Sarah will already know that you would be hard pressed to find anyone who is as kind, generous, and helpful in the hand tool world, But when I opened that parcel on Christmas morning I was knocked sideways.

The first time I met Ollie Sparks, he showed me a plane that he had made that was a new prototype he was working on. Although he had been using it he said he was not happy with it and wanted to change some aspects of the design. For me it was love at first sight. Ollie felt it did not sit quite right in his hand, but to me it fitted like a glove.

At the recent MAC timbers open day I had another chance to handle the plane Of all the works of art on show that day this was the one I could not stop picking up and handling. The ever observant Bill must have noted my enthusiasm that day, and has somehow managed to get Ollie to part with this work of art, and in an immense act of generosity made me custodian of this little beauty.

I sometimes think it is a shame that planes such as these often end up in collectors cabinets, but be assured, this plane will from now on see lots of active duty, Just like my other plane by Bill that I have been using for more than 20 years

For those of you interested in the technical side of things the plane is 4 7/8" long with a 1 1/4" wide cutter.

[/URL

[/URL[URL=http://s1263.photobucket.com/user/richarnold/media/003_zps8f7815d4.jpg.html]