'er indoors pointed to a space in her 'walk in wardrobe' and said...

"A 4 drawer unit would just finish this room off nicely"

so off I marched to retrieve my trusty tape measure.

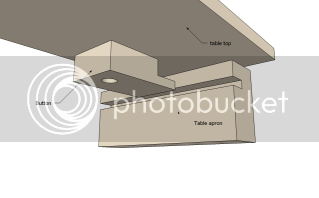

I'm going to use this project to learn a few new skills. I could just cut pieces, screw and glue it together, paint it and job done but there's so much more potential with an iten like this to use and learn new techniques. I will use 'mortice and tenons' for construction of the frame, dovetails to create the drawers and I'll actually make a solid wood top by glueing up some lengths of timber and hand planing smooth. I am going to take a careful approach and try to creat a piece of furniture that is of a reasonable standard. Please dont expect a piece of fine craftsmanship here though.

As I always declare at the start of a WIP some of my methods are probably not correct and you may cringe sometimes and shake your head as I'm doing something but as long as I get to where I need to be - I'm happy.

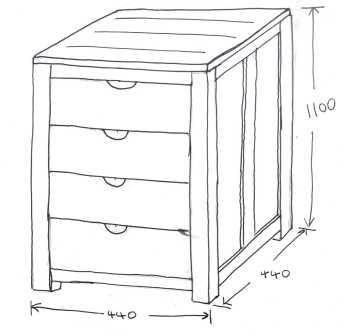

First off I got meself a potta and sat and drew a very rough sketch on the back of a phone bill.

The frame will be made from redwood pine, 28mm x 44mm.

The side panels will be MDF painted white and will sit in a recess.

The drawer cases will be MDF and the fronts will probably be MDF painted white (unless I get any other ideas).

The top will be solid pine.

Frame

So I purchased some nice smooth straight redwood pine and made a rough cut list as follows...

A Legs/posts/uprights : 28 x 44 x 1100 (WxDxH) QTY : 4

B Horizontal braces : 28 x 44 x 392 QTY : 8

C Upright side panel pieces : 28 x 44 x 1005 QTY : 3

NOTE : For B and C I have add 20mm to each end to allow for tenons. So the actual visable length of B is 352 and C is 965.

I set up my saw and cut the 4 pieces labelled A... Look! there's me potta tea!

Then I cut the 8 pieces labelled B and the 3 labelled C (only 2 C's in the picture though!)

To be continued...

"A 4 drawer unit would just finish this room off nicely"

so off I marched to retrieve my trusty tape measure.

I'm going to use this project to learn a few new skills. I could just cut pieces, screw and glue it together, paint it and job done but there's so much more potential with an iten like this to use and learn new techniques. I will use 'mortice and tenons' for construction of the frame, dovetails to create the drawers and I'll actually make a solid wood top by glueing up some lengths of timber and hand planing smooth. I am going to take a careful approach and try to creat a piece of furniture that is of a reasonable standard. Please dont expect a piece of fine craftsmanship here though.

As I always declare at the start of a WIP some of my methods are probably not correct and you may cringe sometimes and shake your head as I'm doing something but as long as I get to where I need to be - I'm happy.

First off I got meself a potta and sat and drew a very rough sketch on the back of a phone bill.

The frame will be made from redwood pine, 28mm x 44mm.

The side panels will be MDF painted white and will sit in a recess.

The drawer cases will be MDF and the fronts will probably be MDF painted white (unless I get any other ideas).

The top will be solid pine.

Frame

So I purchased some nice smooth straight redwood pine and made a rough cut list as follows...

A Legs/posts/uprights : 28 x 44 x 1100 (WxDxH) QTY : 4

B Horizontal braces : 28 x 44 x 392 QTY : 8

C Upright side panel pieces : 28 x 44 x 1005 QTY : 3

NOTE : For B and C I have add 20mm to each end to allow for tenons. So the actual visable length of B is 352 and C is 965.

I set up my saw and cut the 4 pieces labelled A... Look! there's me potta tea!

Then I cut the 8 pieces labelled B and the 3 labelled C (only 2 C's in the picture though!)

To be continued...