Rhyolith

Established Member

Finally got my hands on one of these beasts and a must admit it exceeds expectations so far! The build quality is superb and its quietest belt sander I have heard to date. I believe this type of belt sander is named "Locomotive" because it looks like a railway engine

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

No obvious initial issues other than the bad fitting belt, dirt and a crack in the front handle.

I decided to clean it anyway and check all the mechanical bits, as I think I'd like it to be my main working belt sander. Here I would like some advise:

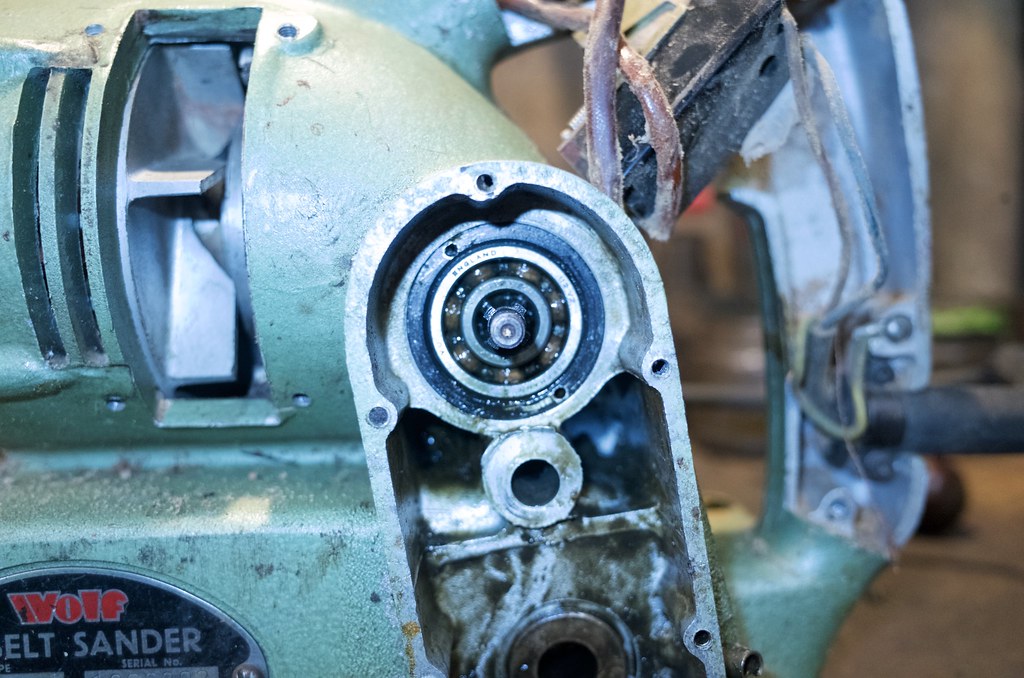

First the gearbox (it has no belt), its greased but the grease looks to me on the dry side. Should I clean and replace or leave alone?

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

There is also what I am pretty sure is a lubrication hole next to this, it leads to the driving pulley I think. The name plate says to use light oil (3 in 1 i assume) on all bearings, but maybe this one needs grease?

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Then there is the seals. It has a few components that are sealed with thin rubber, these disintegrated when i dismantled, I was wondering how to replace them? One is for the gearbox (can see half of it in the picture above) and the other for the dust outlet (broken seal is there):

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Lastly for tonight the switch. Its a tiny bit stiff, feels like it could do with a but of lubrication. Should I lubricated it and what with if so?

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on FlickrNo obvious initial issues other than the bad fitting belt, dirt and a crack in the front handle.

I decided to clean it anyway and check all the mechanical bits, as I think I'd like it to be my main working belt sander. Here I would like some advise:

First the gearbox (it has no belt), its greased but the grease looks to me on the dry side. Should I clean and replace or leave alone?

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on FlickrThere is also what I am pretty sure is a lubrication hole next to this, it leads to the driving pulley I think. The name plate says to use light oil (3 in 1 i assume) on all bearings, but maybe this one needs grease?

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on FlickrThen there is the seals. It has a few components that are sealed with thin rubber, these disintegrated when i dismantled, I was wondering how to replace them? One is for the gearbox (can see half of it in the picture above) and the other for the dust outlet (broken seal is there):

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on FlickrLastly for tonight the switch. Its a tiny bit stiff, feels like it could do with a but of lubrication. Should I lubricated it and what with if so?

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr

Wolf 3" 'Locomotive' Sander by Rhyolith, on Flickr