Having a minor issue, when I push down (even lightly) the belt slowly slides off the wheels. The only way to prevent it is to either manage the downforce carefully (which is ok, but bit hardwork) or adjust it so the belt is pushing right up against the inside of the sander while not under load... neither is ideal.

I have not used belt sanders that much, but have had similar issues with most of the ones i have used. Is this kinda thing part of the course with these machines?

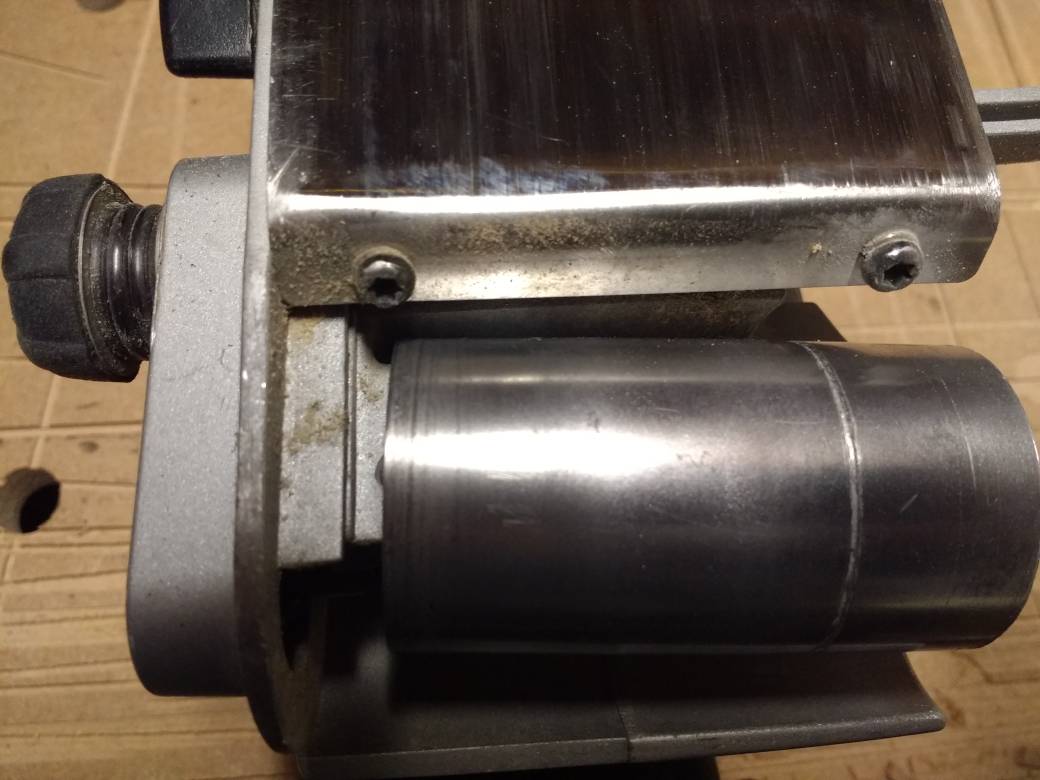

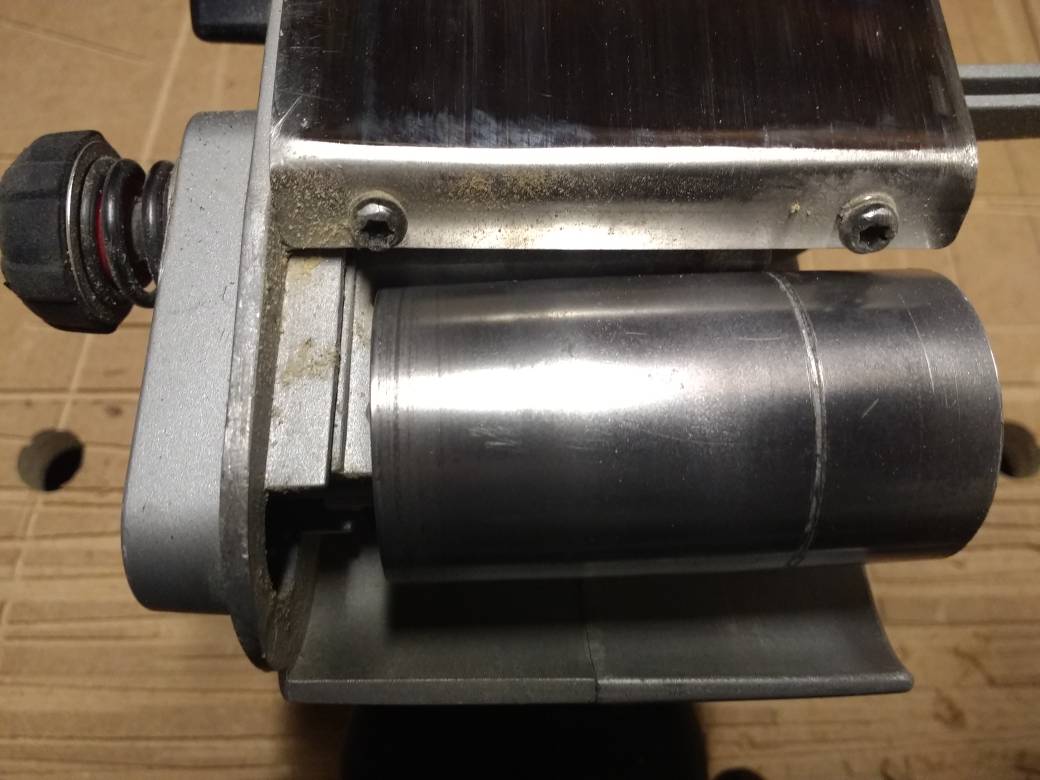

Assuming its meant to be a little better than it is I have taken the Adjuster apart. It works by pushing a flap of metal attached to the front wheel up and down against two ball bearings, the top bearing is up against the adjuster screw and the bottom is atop a spring.

see it laid out here:

R0000037

R0000037 by

Rhyolith, on Flickr

My thinking is that the spring is depressing when a certain load is reach causing the wheel to move and the belt to slide; that would make sense considering the direction the belt is moving. However the spring looks fine to me and I cannot see how it was ever any different... maybe just a design flaw?

There is also this little spring that I cannot figure out, it came out the first time I took the thing apart, but from where exactly I am not sure... I have tried it in several places and it does not seem to make sense anywhere. Could it have something to do with it?

its the one at the mid left.

R0000037

R0000037 by

Rhyolith, on Flickr