Sawdust=manglitter

Established Member

I know... yet another router plane! But I set out to make myself a keeper of a router plane that’s hard wearing enough to last and also wanted to indulge and making something pretty. (Also couldn’t afford to pay for the Veritas router plane which I really fancied!)

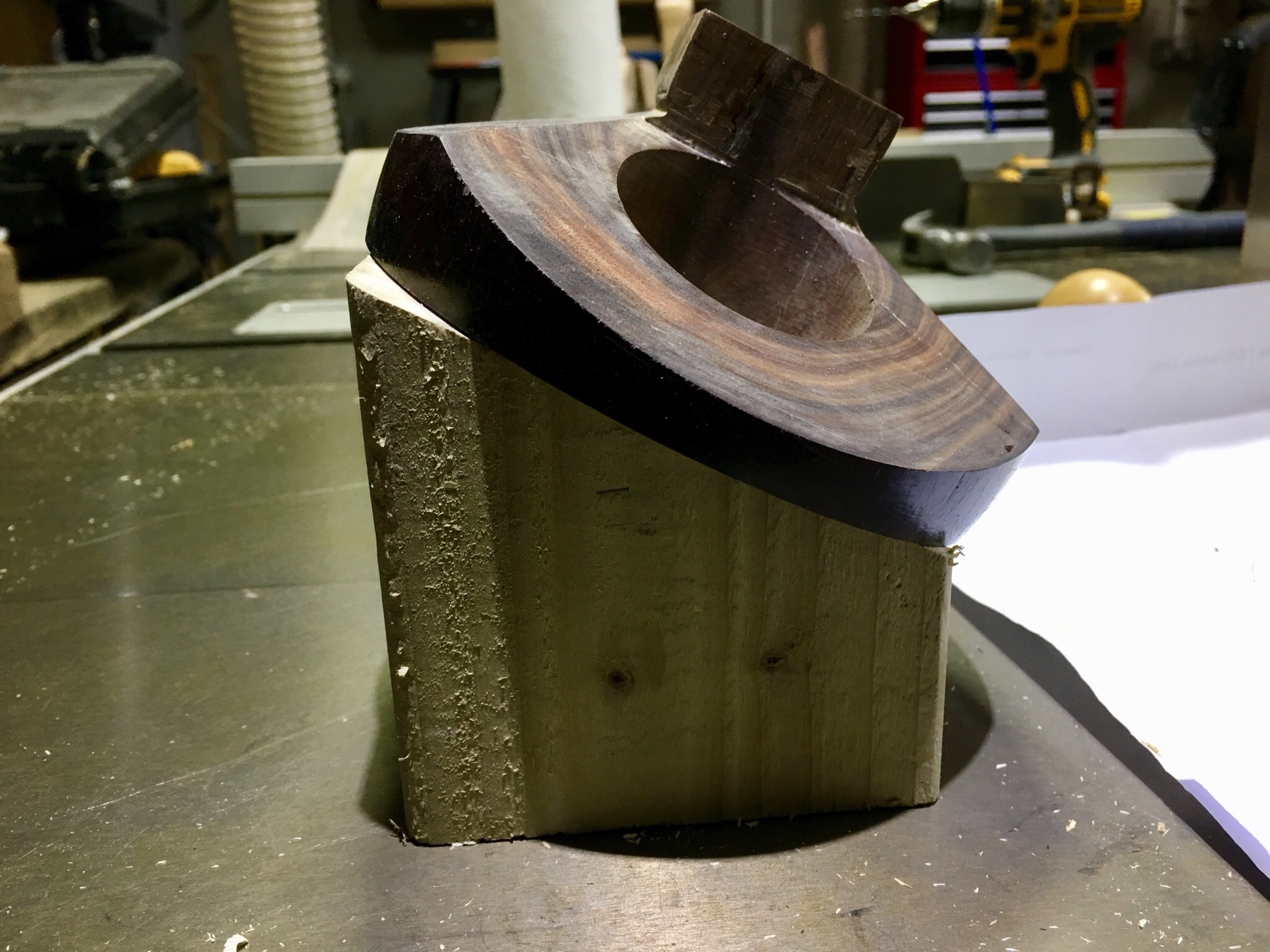

I had an antique Lignum Vitae lawn bowls ball which I won on eBay (turned a mallet out of one already) which I decided to use for the body of the plane. So the first thing i needed to do was to get a flat side to the ball, so in order to safely take the ball through the bandsaw I screwed a piece of scrap through one side of the ball to give it some rigidity and stop it spinning and jamming in the blade.

I sanded the bandsaw cut on the belt sander to give me a flatter face to work from. Next step was to get a parallel flat face on the opposite side of the ball, so achieved this with my biggest Forstner bit (50mm) on the drill press.

Then used the same 50mm Forstner bit to drill the main off centre hole through the body. (I did drill through pith and the area with the most cracks)

I cut the perpendicular flat rear of the router plane by lining up the off centre hole by eye and cut it on the mitre saw.

The next bit was a little precarious. Can’t remember the exact angle I cut, maybe something like 22 degrees, but in order to hold the ball safely I had to clamp a piece of wood through the ball, but I did line it up perpendicular to the mitre saw fence with a machinist square before clamping a little harder that I probably should have.

I had an antique Lignum Vitae lawn bowls ball which I won on eBay (turned a mallet out of one already) which I decided to use for the body of the plane. So the first thing i needed to do was to get a flat side to the ball, so in order to safely take the ball through the bandsaw I screwed a piece of scrap through one side of the ball to give it some rigidity and stop it spinning and jamming in the blade.

I sanded the bandsaw cut on the belt sander to give me a flatter face to work from. Next step was to get a parallel flat face on the opposite side of the ball, so achieved this with my biggest Forstner bit (50mm) on the drill press.

Then used the same 50mm Forstner bit to drill the main off centre hole through the body. (I did drill through pith and the area with the most cracks)

I cut the perpendicular flat rear of the router plane by lining up the off centre hole by eye and cut it on the mitre saw.

The next bit was a little precarious. Can’t remember the exact angle I cut, maybe something like 22 degrees, but in order to hold the ball safely I had to clamp a piece of wood through the ball, but I did line it up perpendicular to the mitre saw fence with a machinist square before clamping a little harder that I probably should have.