Wood spoiler

Established Member

Oh No!

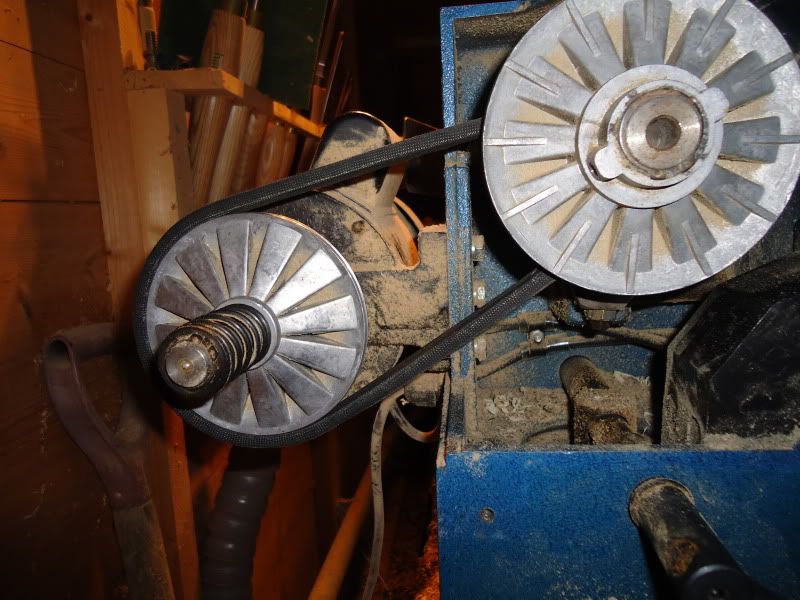

I have shredded my Lathe Drive Belt which Axminster are out of stock of til "early December"

which Axminster are out of stock of til "early December"

What am I going to do? I don't think I can justify a new lathe on the grounds of a broken drive belt, or can I?

I might have to learn to speak with my wife again!

Colin

I have shredded my Lathe Drive Belt

What am I going to do? I don't think I can justify a new lathe on the grounds of a broken drive belt, or can I?

I might have to learn to speak with my wife again!

Colin