Shane

Established Member

Afnoon all.

A while back I purchased a few axi machines. The reason I went for their stuff was initially because of their competitive pricing, close proximity, and their renowned customer service.

I paid them a visit and had a good look at the machines I was interested in to make sure they felt right. Getting a good deal was straight forward, and was offered a good discount because of the nature of the purchase, so no haggling required.

I must emphasize how good their service was, from the moment I walked into the shop up until delivery, the communication was spot on.

Items bought...

AW12BSB2 Saw bench

http://www.axminster.co.uk/product-Axmi ... 714895.htm

AW128PT P/T

http://www.axminster.co.uk/product-Axmi ... 810327.htm

AW19FM morticer

http://www.axminster.co.uk/product-Axmi ... 369280.htm

AWEDE Extractor

http://www.axminster.co.uk/product-Axmi ... 376272.htm

The AW12BSB2 Saw bench...

Assembly was relatively straight forward, thanks to the clear instructions. Two people is definitely required because the cast tops are pretty lumpy.

Once assembled I checked everything was calibrated and level/square. Upon inspection I discovered that the size increments on both the sliding table fence (extension piece doesn't tally with main section for repeat stop cuts) and the rip fence are very dubious, made worse by the fuzzy magnified site on the rip fence. This will be replaced by a flat piece of clear plastic at some point.

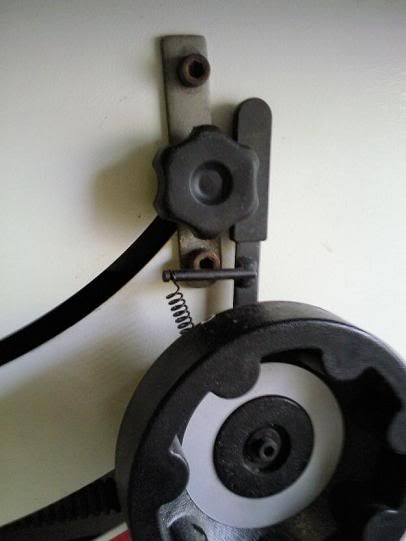

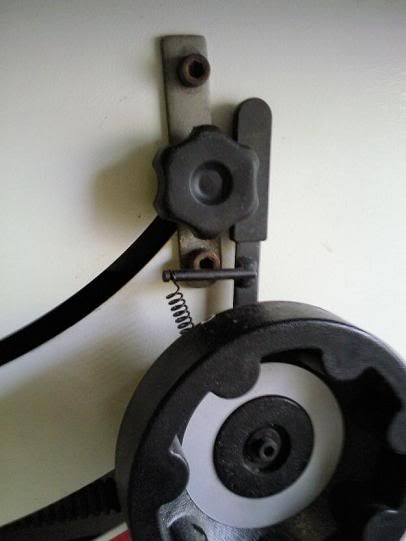

The next issue discovered was upon ripping down a reasonable amount of Ash. The saw tilt lock on mine simply doesn't work, which I believe is more down to a bad design rather then an individual machine fault. Even when the machine wasn't under load I was able to watch the angle marker make it's way along the scale, and settle at three degrees. I checked everything was tight which made no difference. I believe the tilt locking knob needs a much bigger washer to apply more pressure on the saw cabinet face. I wasn't happy with just fitting a bigger washer, so went for the belt and brace option...

With that issue sorted, my next mission was to make it more simple to remove the sliding table fence without the hassle of lifting off the table each time I wanted to switch from cross cut to ripping.

I drilled the bolt access holes out a bit larger, and fitted two 80mm x 8mm SS capheads with two nuts with their hex edges ground off to clear the internal webbing. It is now much quicker to remove.

Once the sliding fence is removed, I wanted to lock the table so I used one of the brackets used on the delivery pallets...

and I fitted a metal tray for the tools (donated by my Fathers titan saw table)

Overall I am very, very happy with this saw, even with the niggles. As noted by others the cast table has a small dip in the middle, but I don't see an issue with this. It is very capable, ripping down 2" Ash no probs at all (with a CMT rip blade). The rip fence itself is excellent, I love the way it locks front and back of the table. It is relatively quiet, and the finish is pretty good considering its price. I would recommend this saw (and no doubt similar looking clones) to anyone, just be prepared to have a bit of a fettle.

AW128PT P/T...

The only problem we had with this one was weight! we used an engine hoist to get it off the pallet because there was no space between the machine and pallet to get a forklift into.

Assembly required was minimal, only fitting the guard and fence, which was good as the instructions for it were the worst chinglish I've come across!

As far as performance goes, this machine is excellent, thicknessing the afore mention Ash (half of it was 11" wide) with ease, giving a very good finish, and calibration remained true throughout the job. I'm glad they stuck with an alu fence on this one opposed to the cast upgrade on the smaller version, or it would be a right nuisance taking on/off

not much more to say on this one really, just very pleased with it.

AW19FM morticer...

Again, assembly was minimal, only requiring fitment of the chisel and length stops

This machine is accurate, and plenty powerful enough for what I need, and build quality is good. not much more to say, it does what it says on the tin, job jobbed!

AWEDE Extractor

More assembly required on this one, but had thorough instructions so no probs.

Suction is plenty for the machines above, just requiring a quick light vacuum of each machine after each big job. Again build quality is fine.

So overall, A big well done to axminster, brilliant value for very capable machines 8)

A while back I purchased a few axi machines. The reason I went for their stuff was initially because of their competitive pricing, close proximity, and their renowned customer service.

I paid them a visit and had a good look at the machines I was interested in to make sure they felt right. Getting a good deal was straight forward, and was offered a good discount because of the nature of the purchase, so no haggling required.

I must emphasize how good their service was, from the moment I walked into the shop up until delivery, the communication was spot on.

Items bought...

AW12BSB2 Saw bench

http://www.axminster.co.uk/product-Axmi ... 714895.htm

AW128PT P/T

http://www.axminster.co.uk/product-Axmi ... 810327.htm

AW19FM morticer

http://www.axminster.co.uk/product-Axmi ... 369280.htm

AWEDE Extractor

http://www.axminster.co.uk/product-Axmi ... 376272.htm

The AW12BSB2 Saw bench...

Assembly was relatively straight forward, thanks to the clear instructions. Two people is definitely required because the cast tops are pretty lumpy.

Once assembled I checked everything was calibrated and level/square. Upon inspection I discovered that the size increments on both the sliding table fence (extension piece doesn't tally with main section for repeat stop cuts) and the rip fence are very dubious, made worse by the fuzzy magnified site on the rip fence. This will be replaced by a flat piece of clear plastic at some point.

The next issue discovered was upon ripping down a reasonable amount of Ash. The saw tilt lock on mine simply doesn't work, which I believe is more down to a bad design rather then an individual machine fault. Even when the machine wasn't under load I was able to watch the angle marker make it's way along the scale, and settle at three degrees. I checked everything was tight which made no difference. I believe the tilt locking knob needs a much bigger washer to apply more pressure on the saw cabinet face. I wasn't happy with just fitting a bigger washer, so went for the belt and brace option...

With that issue sorted, my next mission was to make it more simple to remove the sliding table fence without the hassle of lifting off the table each time I wanted to switch from cross cut to ripping.

I drilled the bolt access holes out a bit larger, and fitted two 80mm x 8mm SS capheads with two nuts with their hex edges ground off to clear the internal webbing. It is now much quicker to remove.

Once the sliding fence is removed, I wanted to lock the table so I used one of the brackets used on the delivery pallets...

and I fitted a metal tray for the tools (donated by my Fathers titan saw table)

Overall I am very, very happy with this saw, even with the niggles. As noted by others the cast table has a small dip in the middle, but I don't see an issue with this. It is very capable, ripping down 2" Ash no probs at all (with a CMT rip blade). The rip fence itself is excellent, I love the way it locks front and back of the table. It is relatively quiet, and the finish is pretty good considering its price. I would recommend this saw (and no doubt similar looking clones) to anyone, just be prepared to have a bit of a fettle.

AW128PT P/T...

The only problem we had with this one was weight! we used an engine hoist to get it off the pallet because there was no space between the machine and pallet to get a forklift into.

Assembly required was minimal, only fitting the guard and fence, which was good as the instructions for it were the worst chinglish I've come across!

As far as performance goes, this machine is excellent, thicknessing the afore mention Ash (half of it was 11" wide) with ease, giving a very good finish, and calibration remained true throughout the job. I'm glad they stuck with an alu fence on this one opposed to the cast upgrade on the smaller version, or it would be a right nuisance taking on/off

not much more to say on this one really, just very pleased with it.

AW19FM morticer...

Again, assembly was minimal, only requiring fitment of the chisel and length stops

This machine is accurate, and plenty powerful enough for what I need, and build quality is good. not much more to say, it does what it says on the tin, job jobbed!

AWEDE Extractor

More assembly required on this one, but had thorough instructions so no probs.

Suction is plenty for the machines above, just requiring a quick light vacuum of each machine after each big job. Again build quality is fine.

So overall, A big well done to axminster, brilliant value for very capable machines 8)