Next up out of the goody box is this nice little bullnose plane - well, it was nice once, and it could be again - but hardly inspiring here:

but at least there seem to be no cracks or chips around the mouth:

For this job, I used Micromesh - another tip from Jim. Apparently it was developed for grinding optics and suchlike; for me, the key features are that it seems to be everlasting, and the amount you remove is easily controlled. I bought an assorted pack of small sheets on eBay, and so far I have only used two sheets - one fairly coarse and the other one fine.

It's washable - under the tap, or leave it in your pocket and put it through the machine.

Here is the plane dismantled; I've rubbed it hard with a coarse rag, but it's going to need a bit more than that.

Here I've used the coarser grade, wrapped around a cork block and lubricated with a quick squirt of WD40:

I then wiped the slurry of rust and WD40 off with a rag:

It's then just a question of doing this all over. To get in the nooks and crannies, I just wrapped the micromesh around a stick or my finger. Having gone over the plane once, I switched to the finer grade and repeated.

This got it nice and rust free and smooth on the working surfaces but took off almost no steel. The difference with this abrasive is that it seems to give you lots of control over how much you remove; you can just stop when you like the look of it, without leaving scratches.

As an experiment at this stage, I used a smear of MAAS polish (available on-line or from Lakeland kitchen shops) - this did darken the cloth so must have removed something; I think it probably helped in getting the rust out of the bit of pitting on the side.

To finish off, I gave the plane a quick once-over with the Renaissance Wax to prevent any further rusting (and make it nice to handle) and to buff up the rosewood wedge. I also sharpened the iron, which looks as if it has been cut down from a bigger one, but quite neatly.

Here's the finished article, complete with shavings - I hope you'll agree that it now looks like a tool which has been properly looked after, not one that has been neglected.

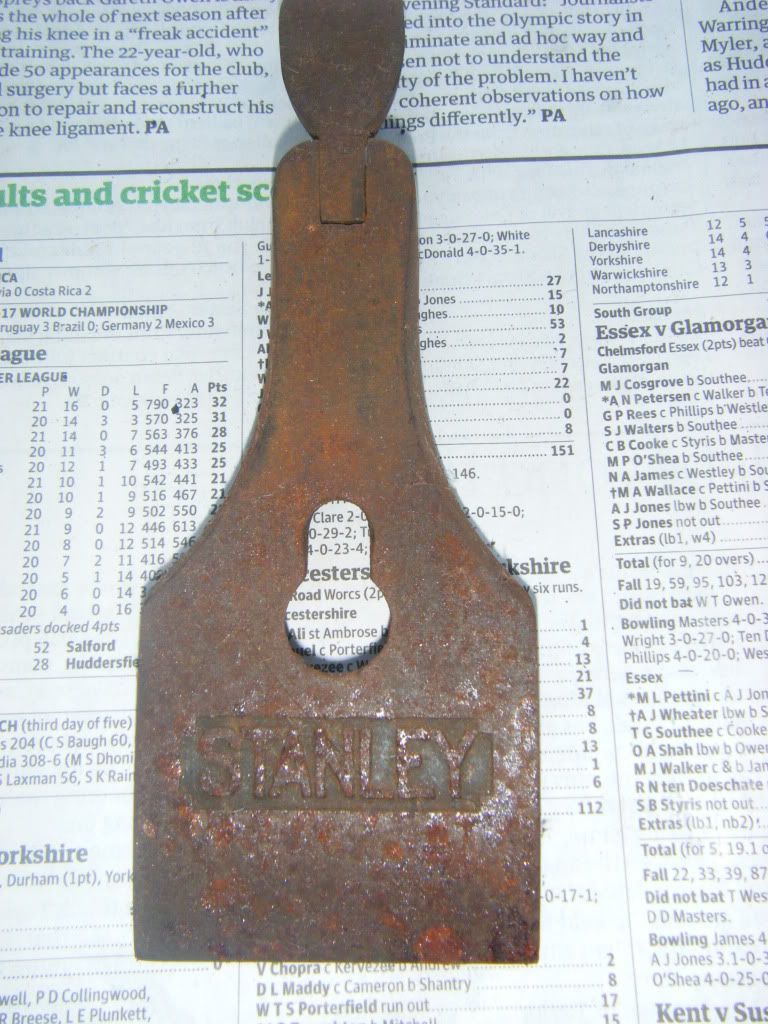

and as a bonus the maker's name is revealed (alongside some old hammer marks!)

but at least there seem to be no cracks or chips around the mouth:

For this job, I used Micromesh - another tip from Jim. Apparently it was developed for grinding optics and suchlike; for me, the key features are that it seems to be everlasting, and the amount you remove is easily controlled. I bought an assorted pack of small sheets on eBay, and so far I have only used two sheets - one fairly coarse and the other one fine.

It's washable - under the tap, or leave it in your pocket and put it through the machine.

Here is the plane dismantled; I've rubbed it hard with a coarse rag, but it's going to need a bit more than that.

Here I've used the coarser grade, wrapped around a cork block and lubricated with a quick squirt of WD40:

I then wiped the slurry of rust and WD40 off with a rag:

It's then just a question of doing this all over. To get in the nooks and crannies, I just wrapped the micromesh around a stick or my finger. Having gone over the plane once, I switched to the finer grade and repeated.

This got it nice and rust free and smooth on the working surfaces but took off almost no steel. The difference with this abrasive is that it seems to give you lots of control over how much you remove; you can just stop when you like the look of it, without leaving scratches.

As an experiment at this stage, I used a smear of MAAS polish (available on-line or from Lakeland kitchen shops) - this did darken the cloth so must have removed something; I think it probably helped in getting the rust out of the bit of pitting on the side.

To finish off, I gave the plane a quick once-over with the Renaissance Wax to prevent any further rusting (and make it nice to handle) and to buff up the rosewood wedge. I also sharpened the iron, which looks as if it has been cut down from a bigger one, but quite neatly.

Here's the finished article, complete with shavings - I hope you'll agree that it now looks like a tool which has been properly looked after, not one that has been neglected.

and as a bonus the maker's name is revealed (alongside some old hammer marks!)