RogerS

Established Member

I thought that some folk might be interested in the process I go through when making up custom spindle moulder cutters. This is how I do it. Others may/will do it differently.

Guess the first question is ‘Why would you want to use them ?’. A couple of reasons spring to mind.

Method 1 - is to match an existing profile in a door or window etc that one is making a replacement part for. For this my preferred method is to get some cling film and two-part car body filler. Mix up some filler, take a sheet of cling film and put it over your palm, slap the filler on top followed by another sheet of cling film and then hold the whole lot over the original moulding making sure you get the filler into all the nooks and crannies in the original moulding. It can get a bit warm while the filler hardens. Once hard, take a slice through the filler that is now a profile of your moulding, draw up/photograph/whatever and send it to your preferred supplier of custom cutters.

Method 2 - is often used when, for example, you want to create a period moulding on a door or architrave and the pattern for the moulding is not available from usual sources.

But first a bit of history. Our house was built in 1754. In the 1960’s, there was a plan to build a large reservoir in the North East. Two sites were in play - one based around the Irthing Gorge and the other Kielder. A London-based couple - the Darlings - bought the house together with a swathe of river frontage. Had Irthing got the go-ahead then they reckoned they’d be sitting on a tourist trap AKA gold mine. But Kielder won the day and the Darling bar stewards simply walked away and let this Georgian house rot. By the mid-1970’s all that was left were the gable ends, the back wall and some of the front wall. The roof had totally gone so allowing all the original Georgian interior to rot. Bar stewards. The house was eventually bought back from them in the 1970’s and renovated - after a fashion. Architraves made from decking, for example !

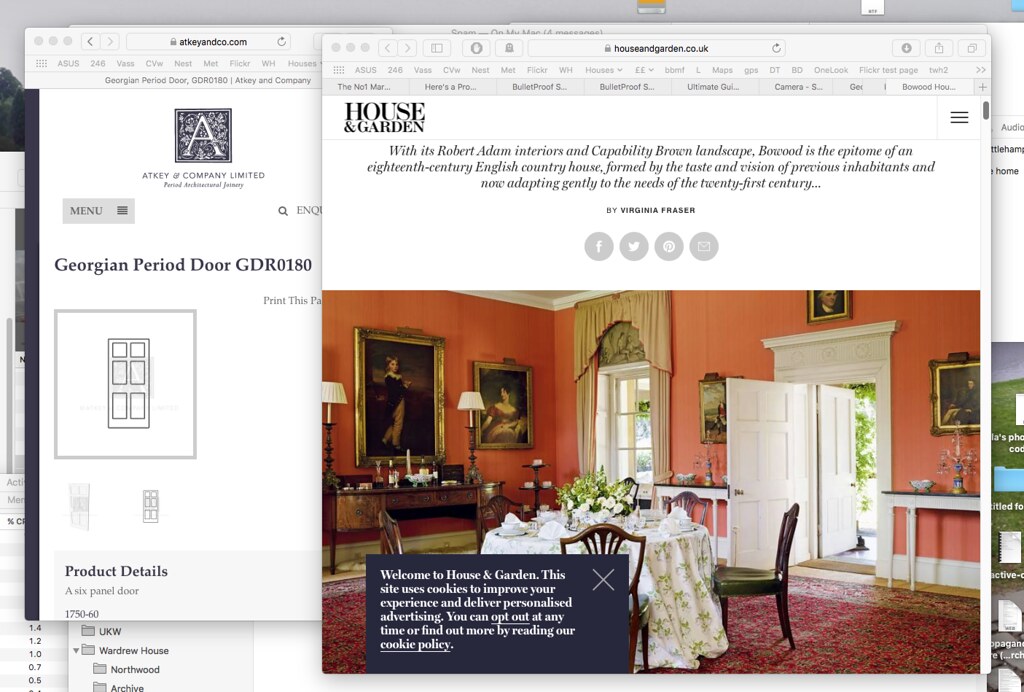

We’re trying to bring back a little bit more authenticism. So CD (Chief Designer) carried out some research and liked this door by Robert Adams - designed and made at a similar time to our house.

Further research discovered a company called Atkey who will make doors, architraves and skirting to the same design as the originals. Albeit at a price. But they do have a good website with lots of diagrams including this door from Bowood House. CD then chose architrave and skirting to suit.

Now I can’t post their pictures as they are copyright but you can see what we chose directly from their website

https://atkeyandco.com/product/georgian ... r-gdr0180/

https://atkeyandco.com/product/georgian ... g-gdm0180/

https://atkeyandco.com/product/georgian ... e-gar0195/

https://atkeyandco.com/product/georgian ... d-gsk0189/

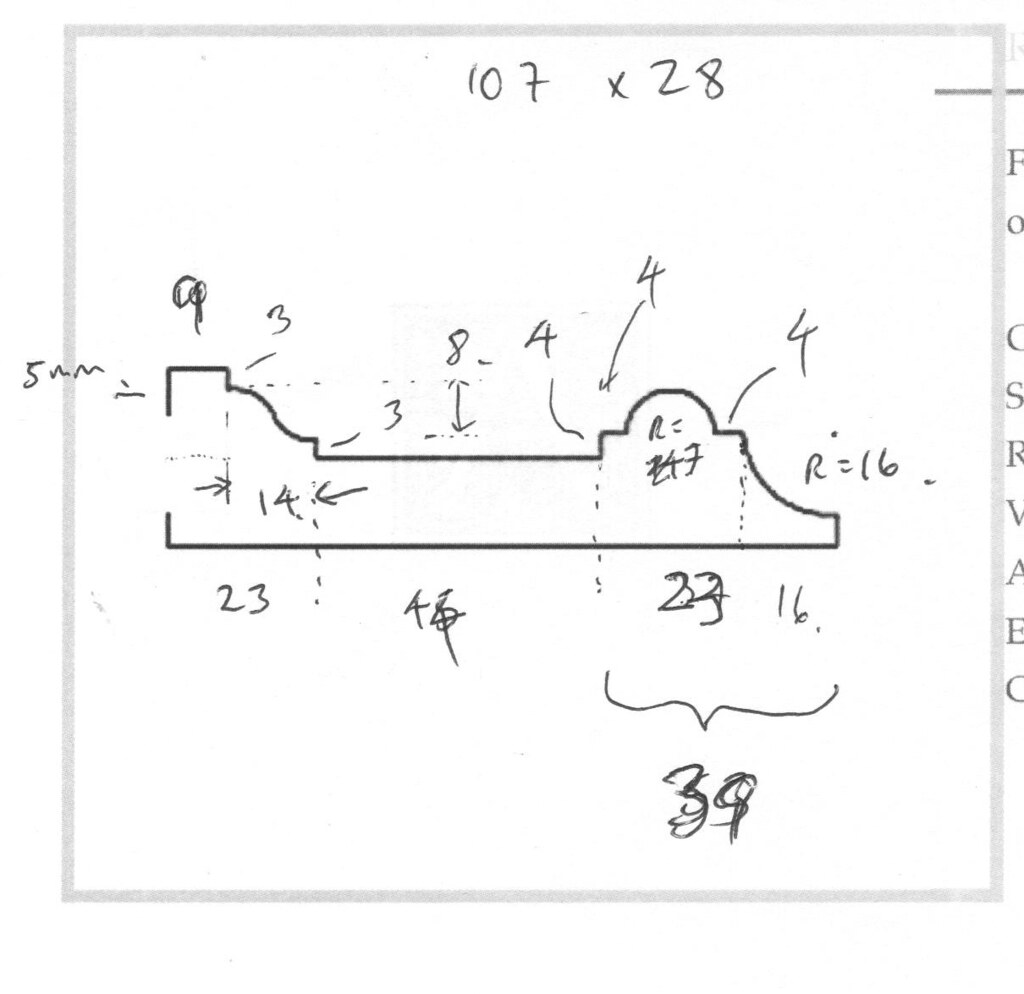

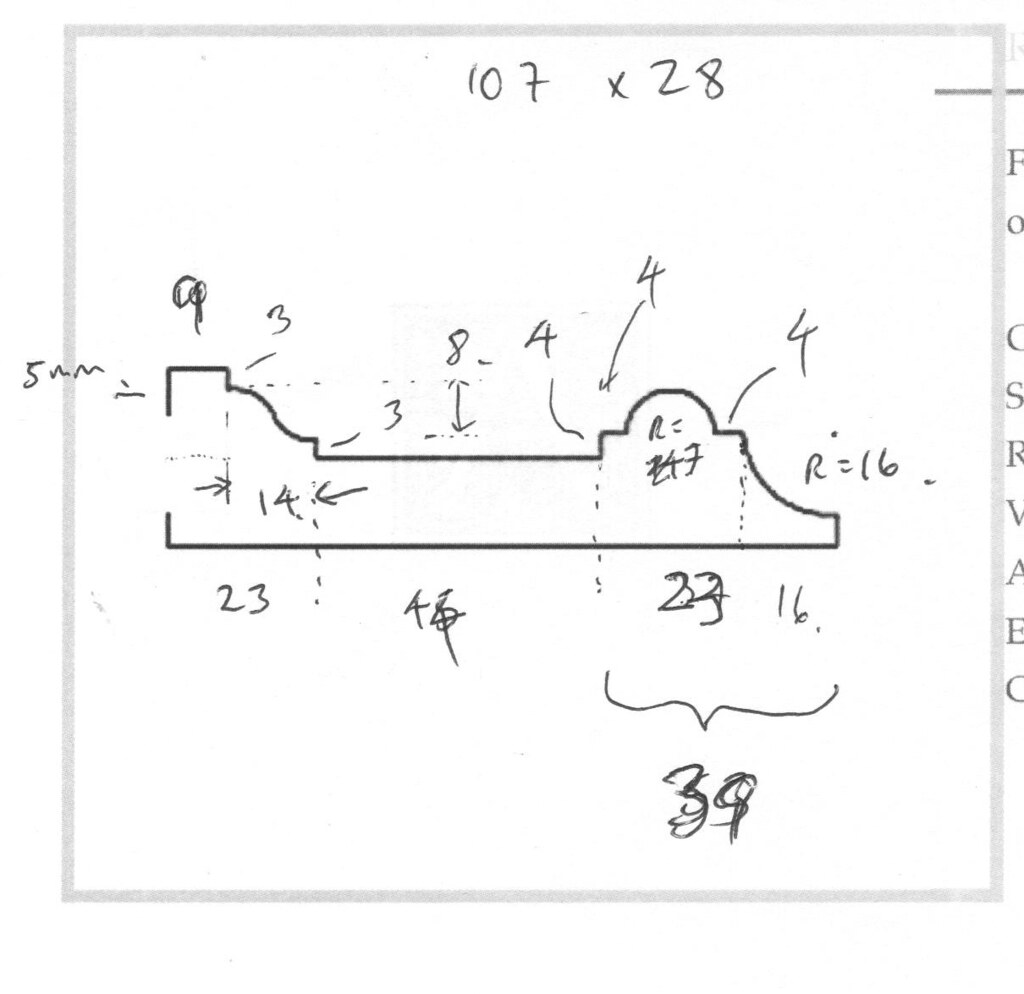

So taking a cross-section of the moulding from their website, they state the overall dimensions, I make a simple four cell spreadsheet that will let me take the dimensions from the printout and convert them to actual size. I then rough sketch the drawings with dimensions thus.

Architrave - note two cutters required due to the size of the architrave

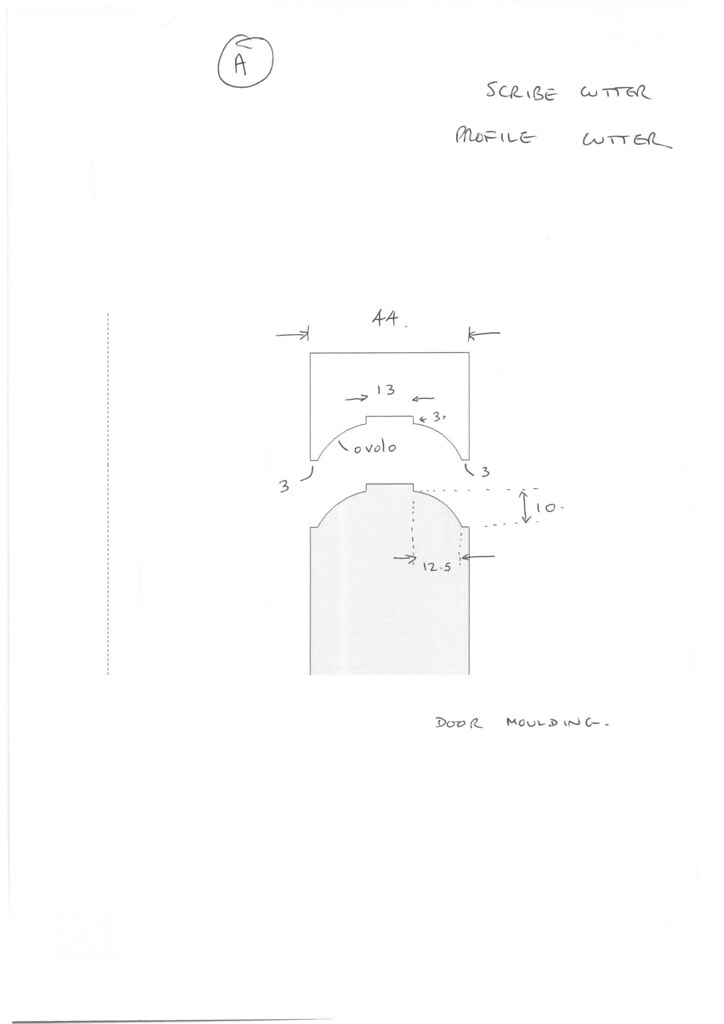

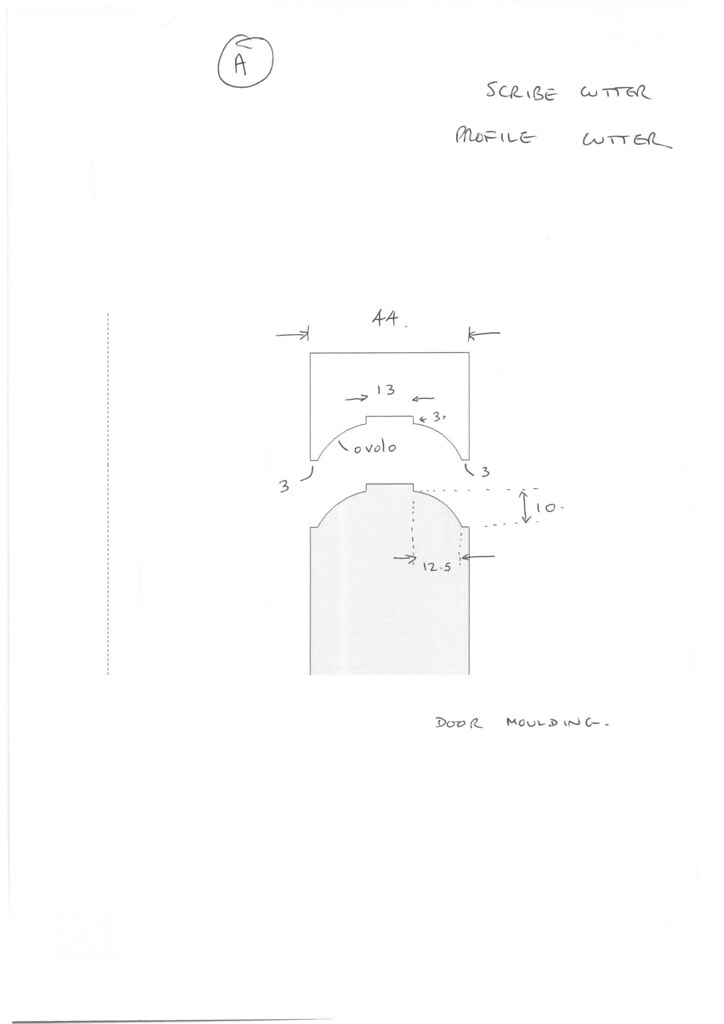

Door moulding - note two cutters required (scribe and profile) and a proper ovolo

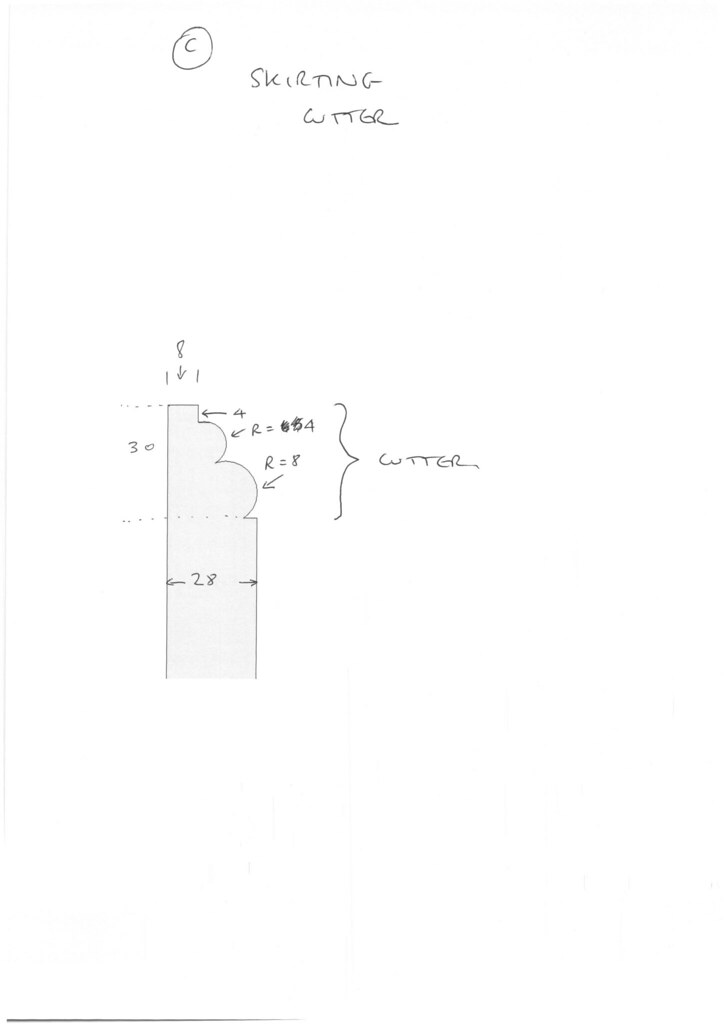

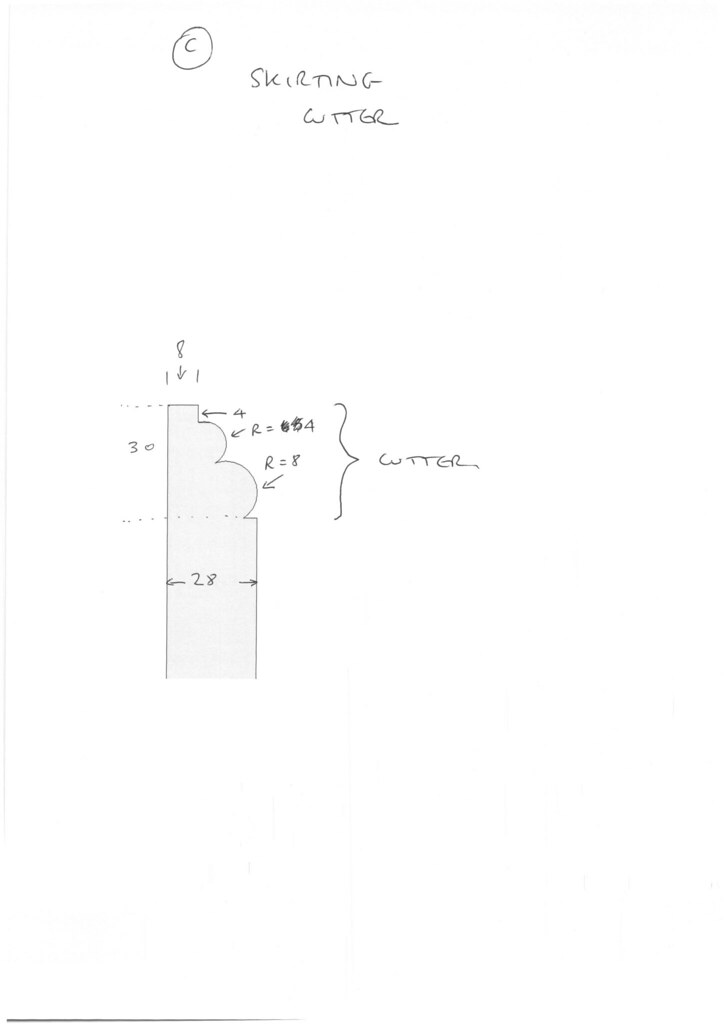

Skirting

You can cross-reference these back to the profiles on the Atkey site.

At this point I like to send these drawings off to the supplier for a rough check that they are ‘doable’. The reason for this is that my original idea was to do the door profile and scribe in one pass with a groove in for the panel but I was told that they couldn’t machine up the small groove for the panel. So the door will now be a two pass moulding process.

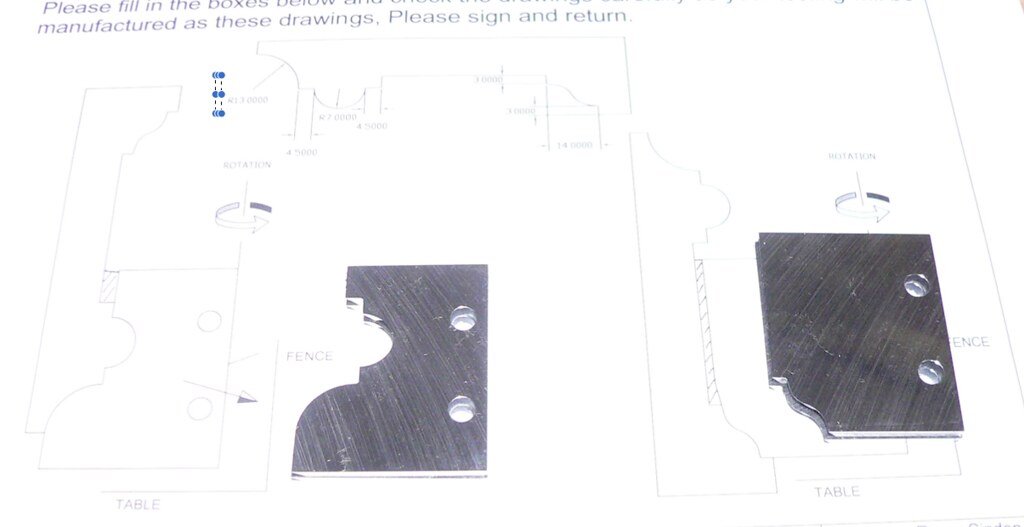

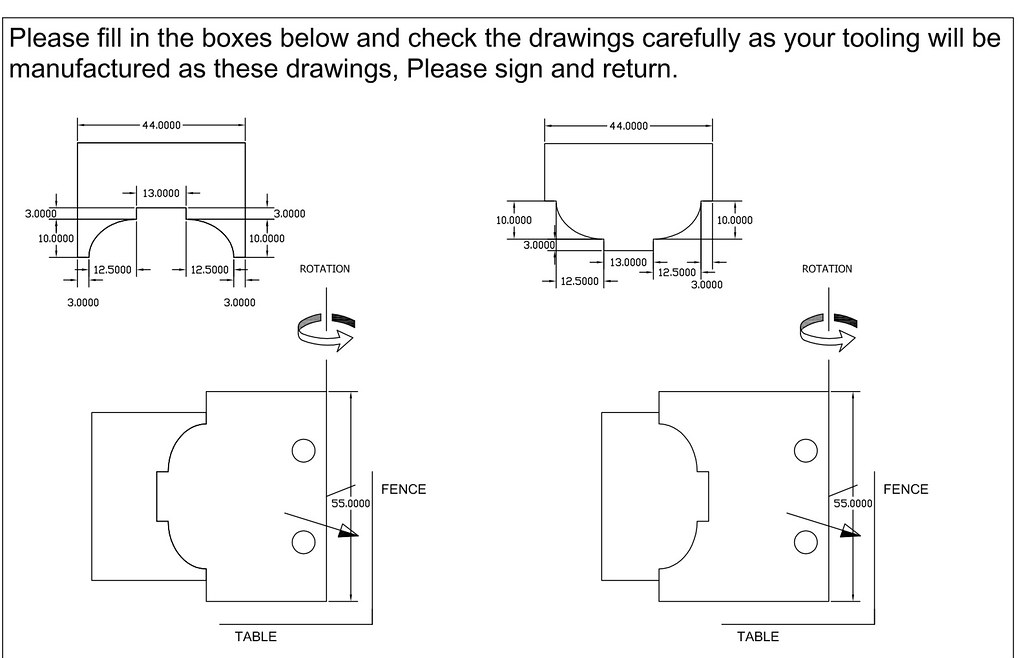

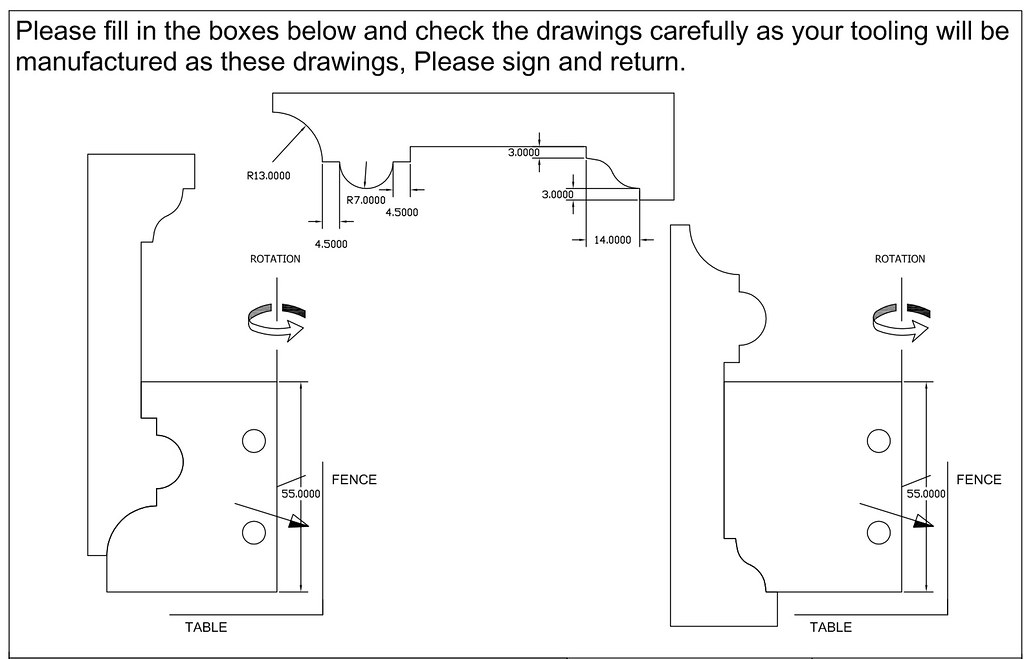

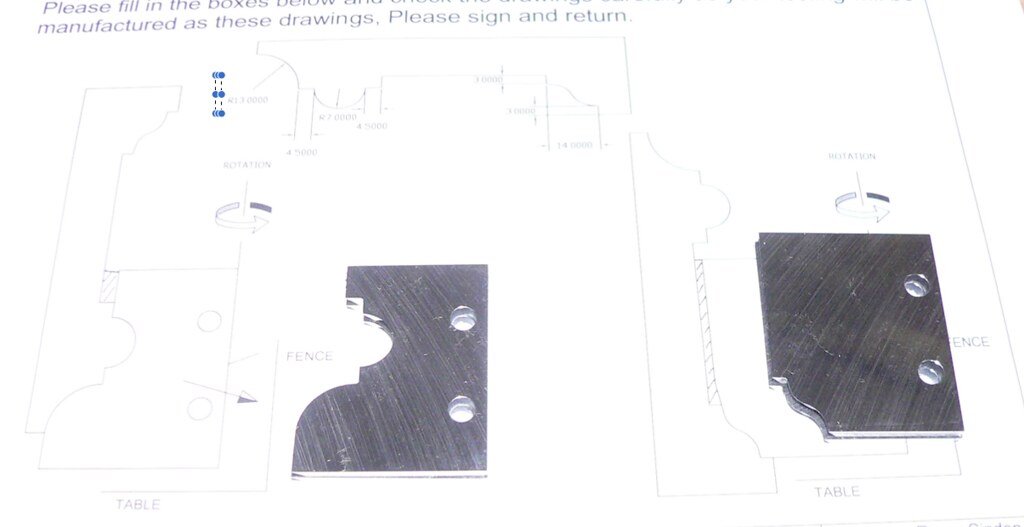

If they’ve passed their sanity check then the next stage is for the supplier (I’m using Whitehill in this instance but other suppliers are available) to draw up proper drawings thus …

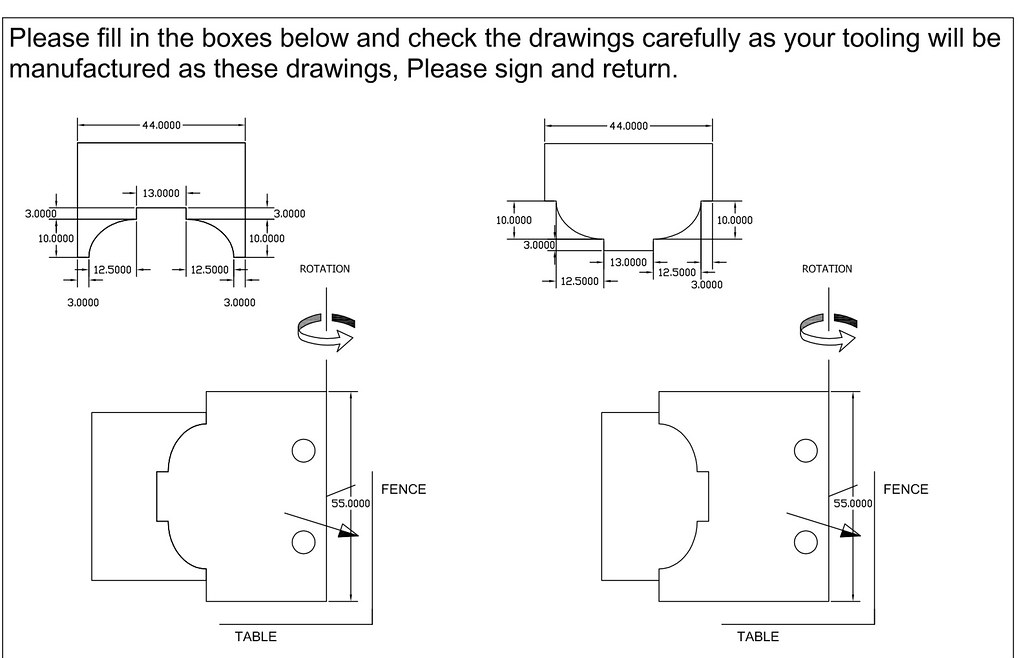

Door

All good.

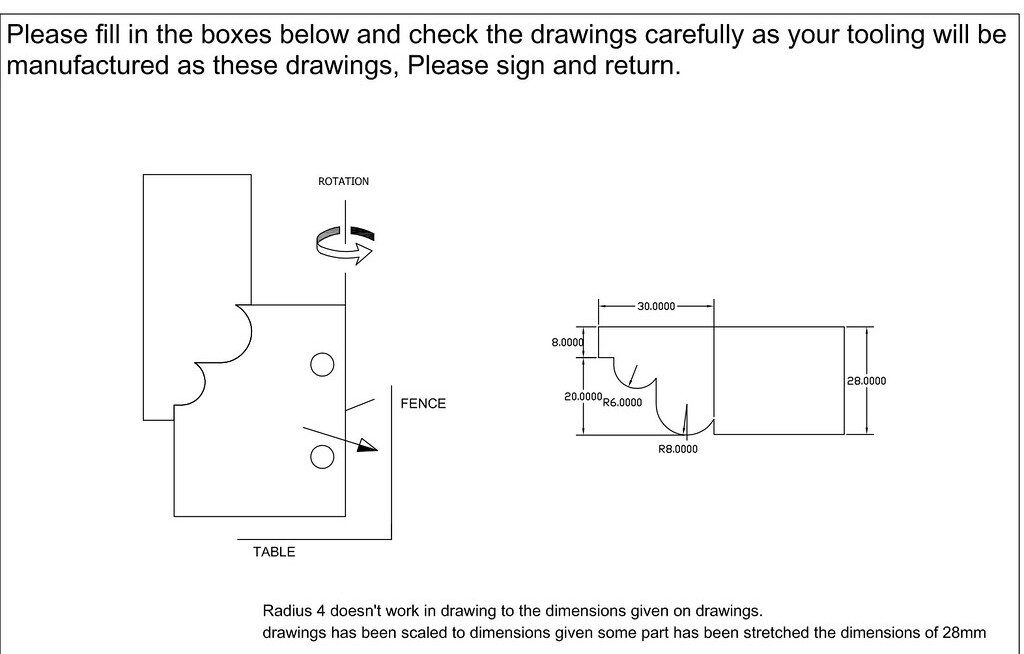

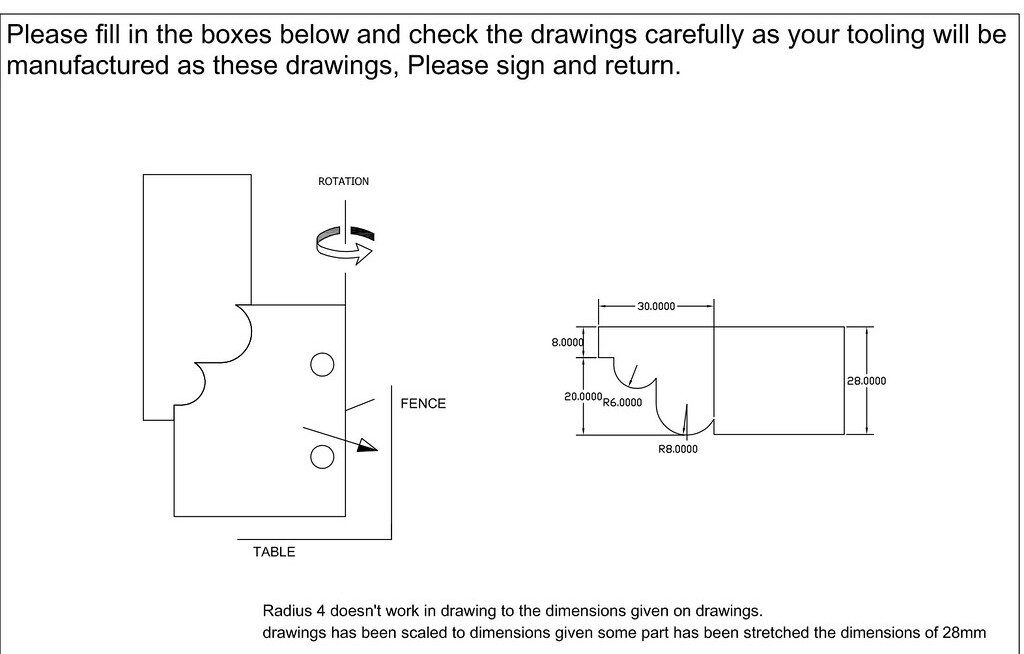

Skirting - Rev 1

Note their comment at the bottom and referring the drawing to the Atkey profile it certainly looks wrong. Further inspection showed I’d cocked up on the initial drawing and the width of the skirting at this point is 22mm and not 28mm

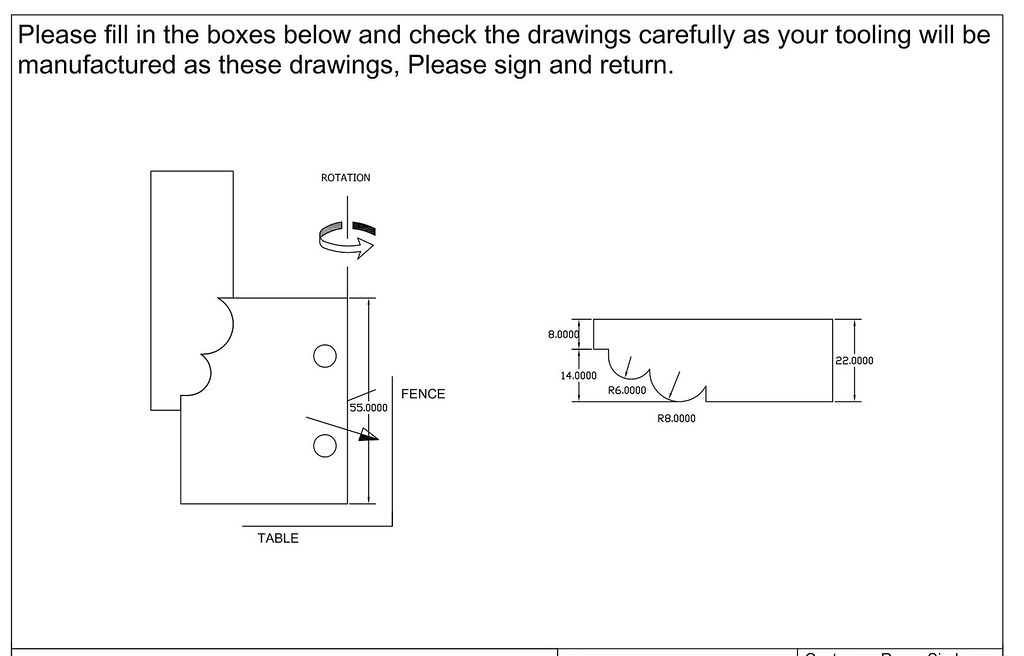

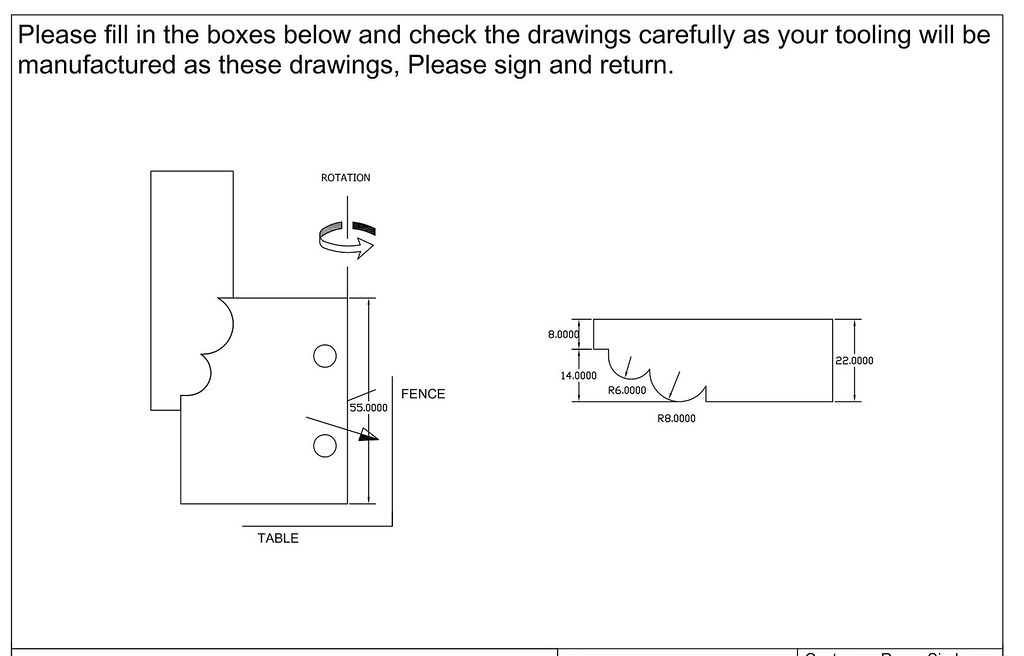

Skirting - Rev 2

Spot on

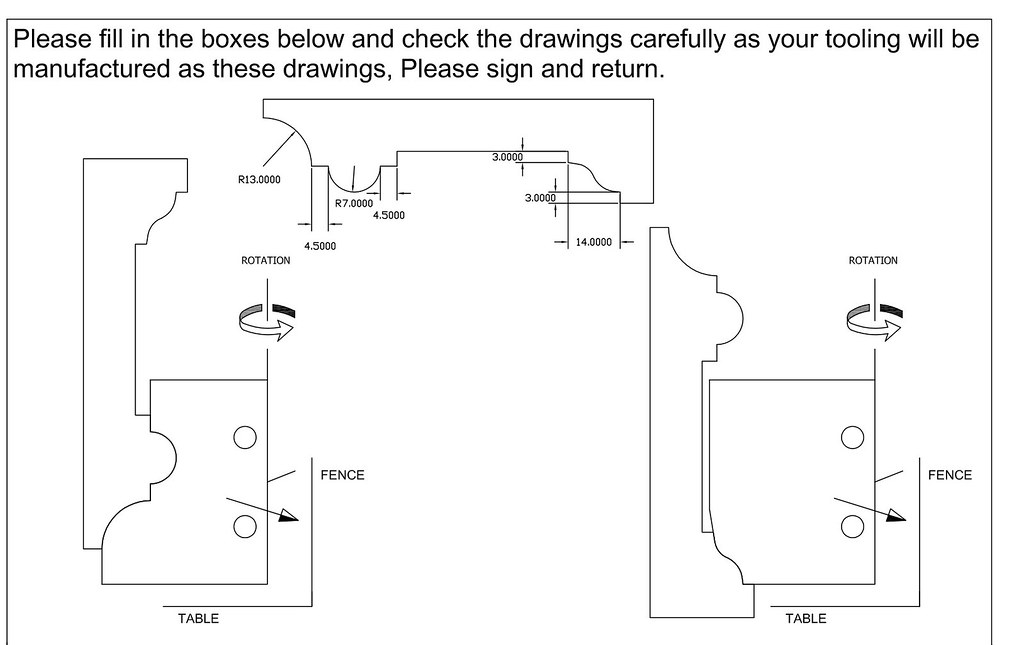

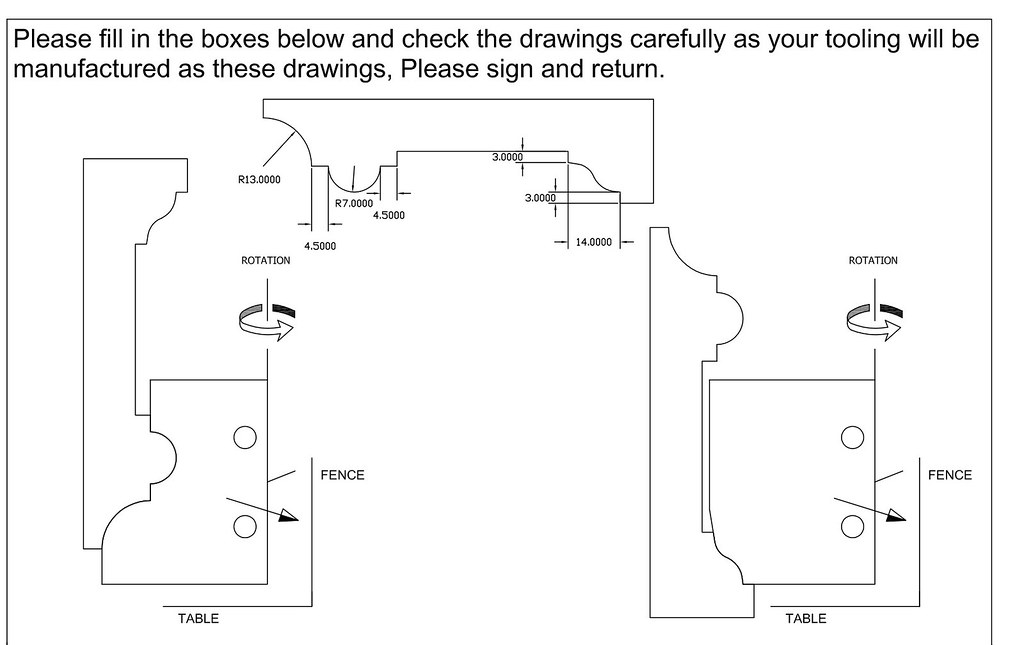

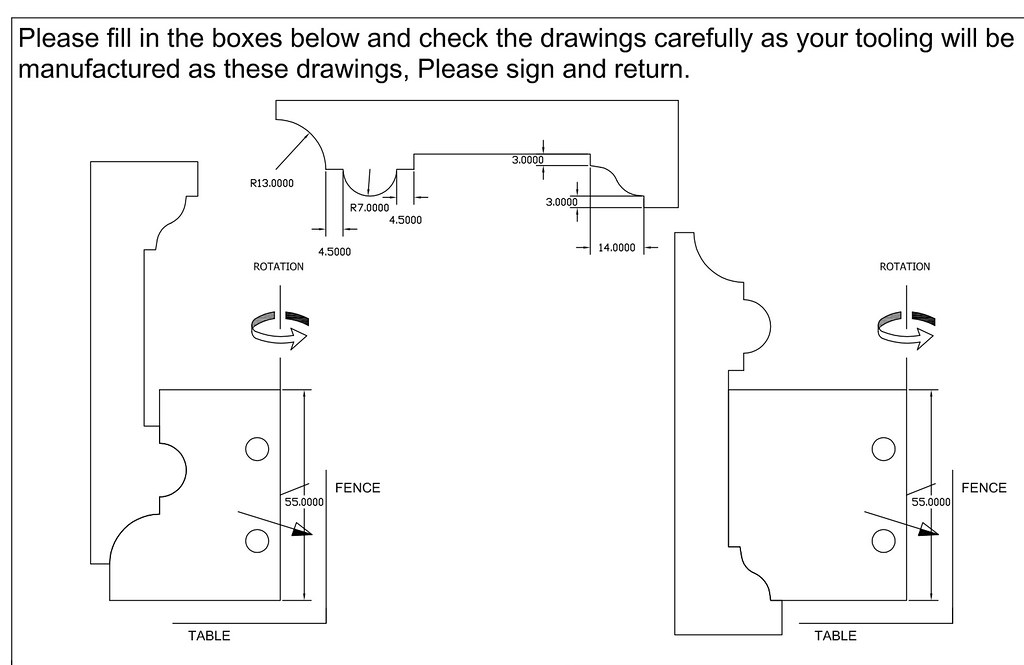

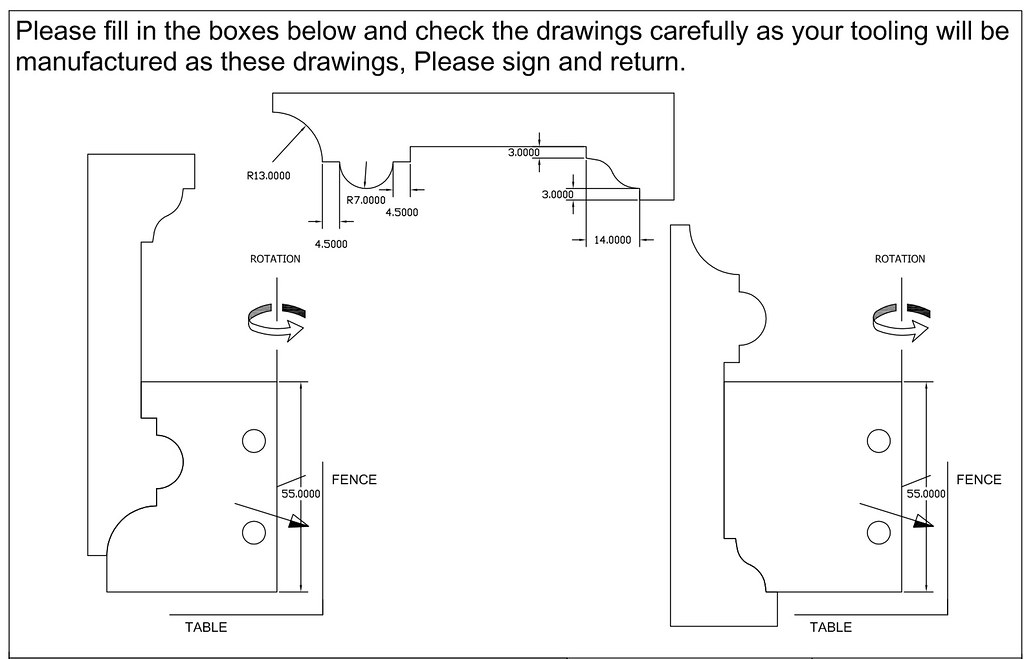

Architrave - Rev 1

I wasn’t sure how this one would pan out because sometimes if the size and/or shape of the profile is such then you need a tilting spindle moulder (which I no longer have). But no tilt needed here. However, what I did pick up was that I could get the cutters altered to make the rebate as part of their profile and so cut down on the number of passes through the spindle moulder.

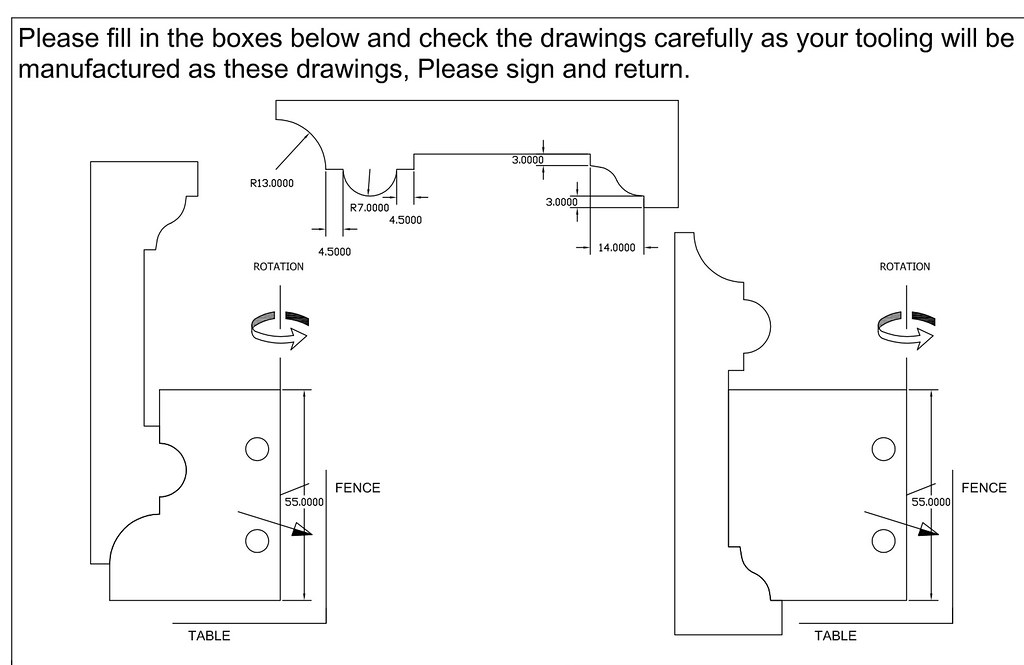

Architrave - Rev 2

Note that they missed out the requested change to the profile cutter on the left.

Architrave - Rev 3

All good.

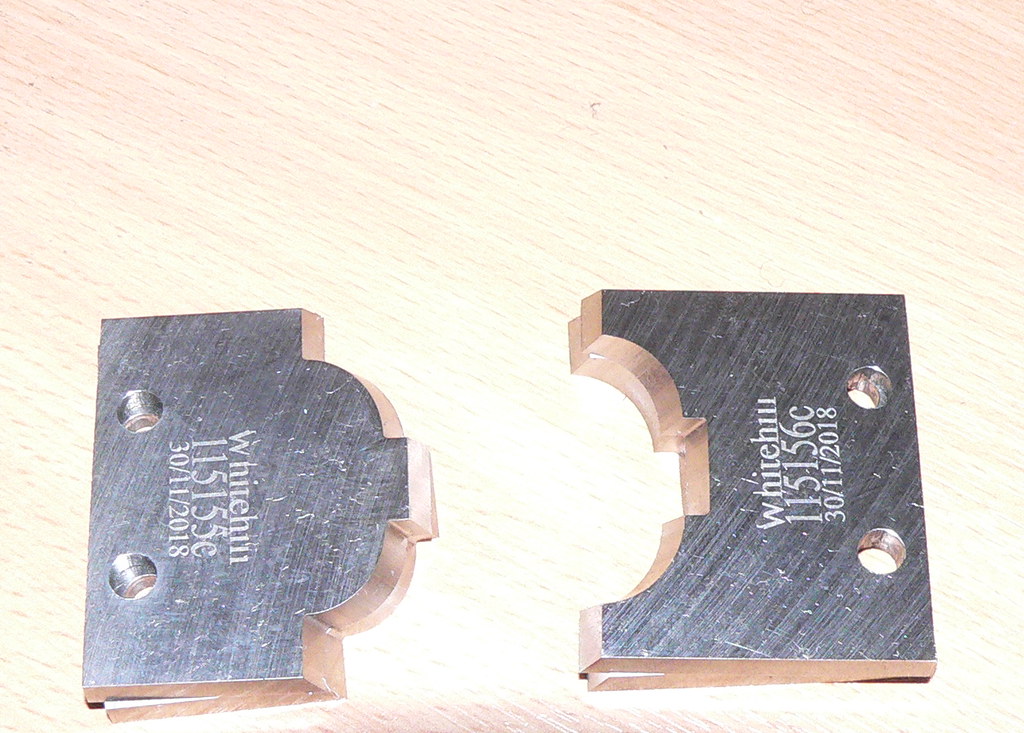

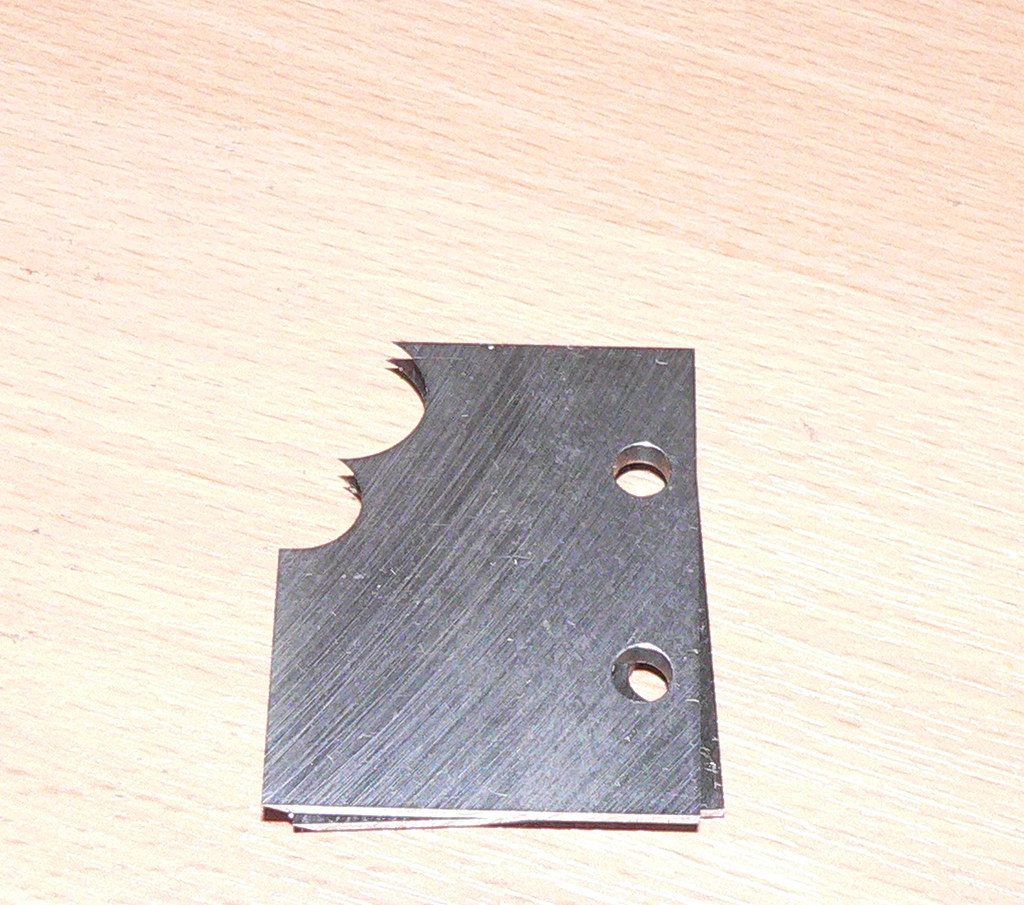

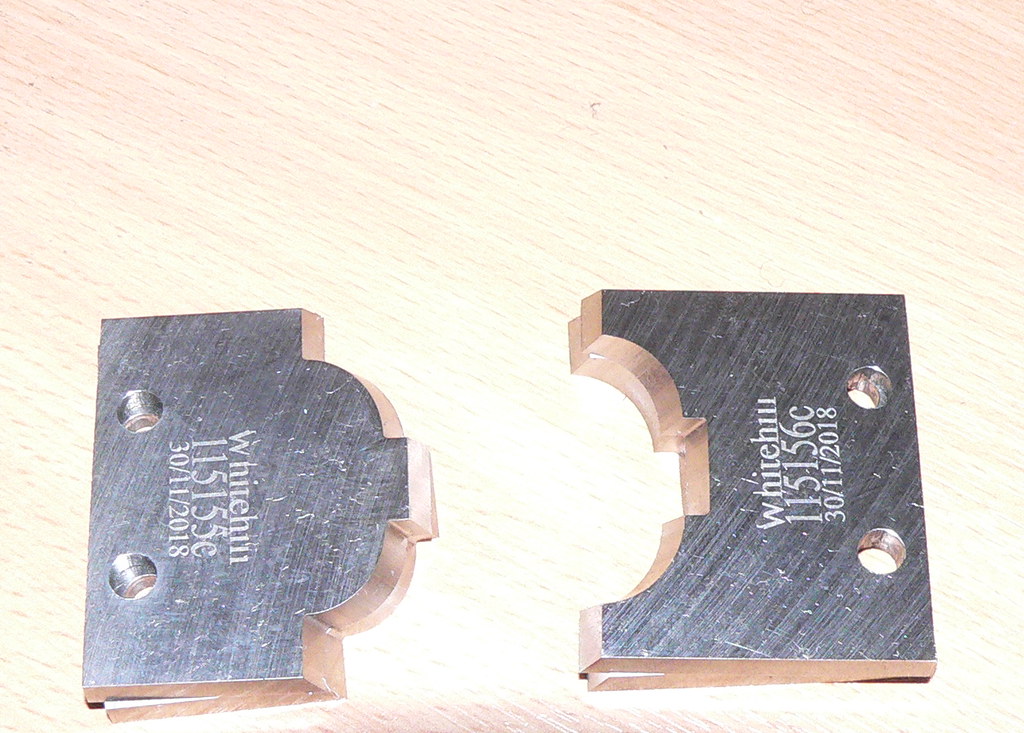

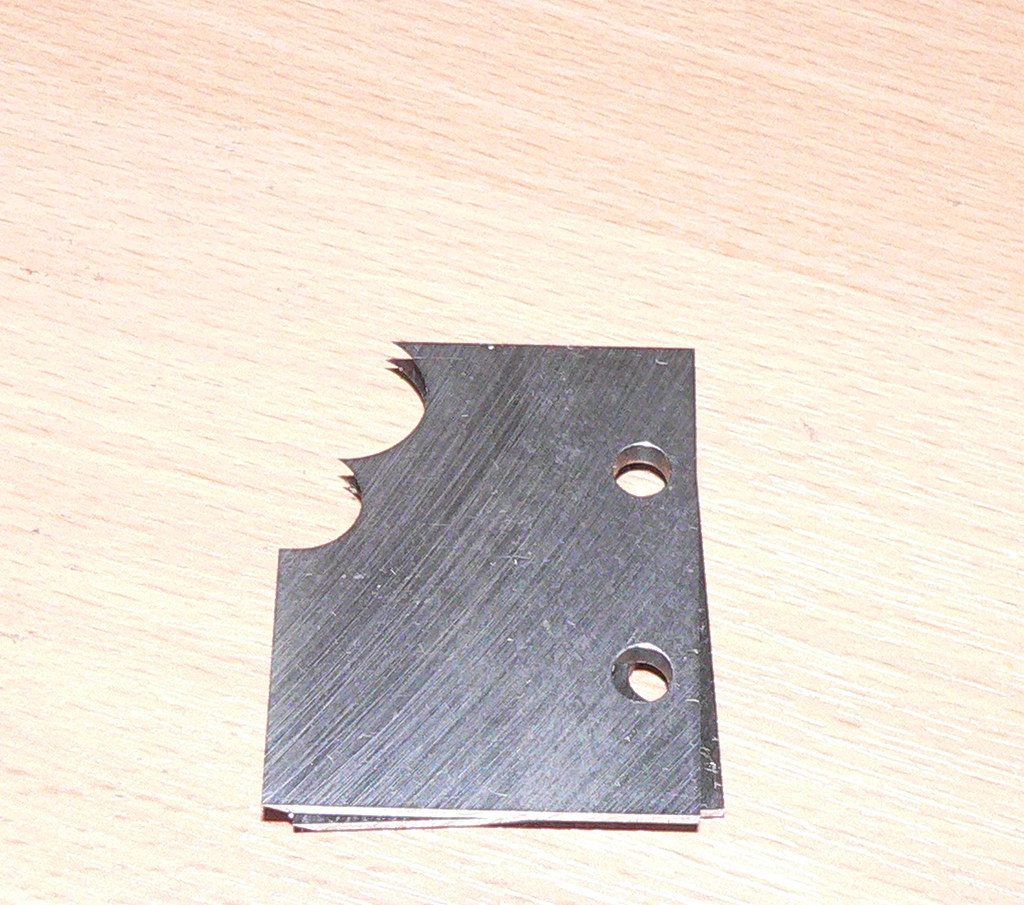

And a few days later, the courier brought me these cutters. Chuffed to bits. Cost £60 a pair + VAT

Guess the first question is ‘Why would you want to use them ?’. A couple of reasons spring to mind.

Method 1 - is to match an existing profile in a door or window etc that one is making a replacement part for. For this my preferred method is to get some cling film and two-part car body filler. Mix up some filler, take a sheet of cling film and put it over your palm, slap the filler on top followed by another sheet of cling film and then hold the whole lot over the original moulding making sure you get the filler into all the nooks and crannies in the original moulding. It can get a bit warm while the filler hardens. Once hard, take a slice through the filler that is now a profile of your moulding, draw up/photograph/whatever and send it to your preferred supplier of custom cutters.

Method 2 - is often used when, for example, you want to create a period moulding on a door or architrave and the pattern for the moulding is not available from usual sources.

But first a bit of history. Our house was built in 1754. In the 1960’s, there was a plan to build a large reservoir in the North East. Two sites were in play - one based around the Irthing Gorge and the other Kielder. A London-based couple - the Darlings - bought the house together with a swathe of river frontage. Had Irthing got the go-ahead then they reckoned they’d be sitting on a tourist trap AKA gold mine. But Kielder won the day and the Darling bar stewards simply walked away and let this Georgian house rot. By the mid-1970’s all that was left were the gable ends, the back wall and some of the front wall. The roof had totally gone so allowing all the original Georgian interior to rot. Bar stewards. The house was eventually bought back from them in the 1970’s and renovated - after a fashion. Architraves made from decking, for example !

We’re trying to bring back a little bit more authenticism. So CD (Chief Designer) carried out some research and liked this door by Robert Adams - designed and made at a similar time to our house.

Further research discovered a company called Atkey who will make doors, architraves and skirting to the same design as the originals. Albeit at a price. But they do have a good website with lots of diagrams including this door from Bowood House. CD then chose architrave and skirting to suit.

Now I can’t post their pictures as they are copyright but you can see what we chose directly from their website

https://atkeyandco.com/product/georgian ... r-gdr0180/

https://atkeyandco.com/product/georgian ... g-gdm0180/

https://atkeyandco.com/product/georgian ... e-gar0195/

https://atkeyandco.com/product/georgian ... d-gsk0189/

So taking a cross-section of the moulding from their website, they state the overall dimensions, I make a simple four cell spreadsheet that will let me take the dimensions from the printout and convert them to actual size. I then rough sketch the drawings with dimensions thus.

Architrave - note two cutters required due to the size of the architrave

Door moulding - note two cutters required (scribe and profile) and a proper ovolo

Skirting

You can cross-reference these back to the profiles on the Atkey site.

At this point I like to send these drawings off to the supplier for a rough check that they are ‘doable’. The reason for this is that my original idea was to do the door profile and scribe in one pass with a groove in for the panel but I was told that they couldn’t machine up the small groove for the panel. So the door will now be a two pass moulding process.

If they’ve passed their sanity check then the next stage is for the supplier (I’m using Whitehill in this instance but other suppliers are available) to draw up proper drawings thus …

Door

All good.

Skirting - Rev 1

Note their comment at the bottom and referring the drawing to the Atkey profile it certainly looks wrong. Further inspection showed I’d cocked up on the initial drawing and the width of the skirting at this point is 22mm and not 28mm

Skirting - Rev 2

Spot on

Architrave - Rev 1

I wasn’t sure how this one would pan out because sometimes if the size and/or shape of the profile is such then you need a tilting spindle moulder (which I no longer have). But no tilt needed here. However, what I did pick up was that I could get the cutters altered to make the rebate as part of their profile and so cut down on the number of passes through the spindle moulder.

Architrave - Rev 2

Note that they missed out the requested change to the profile cutter on the left.

Architrave - Rev 3

All good.

And a few days later, the courier brought me these cutters. Chuffed to bits. Cost £60 a pair + VAT