woodfarmer

Established Member

Hi all

Rang Aminster today and they will have the lathes i want to see in store for me in November.

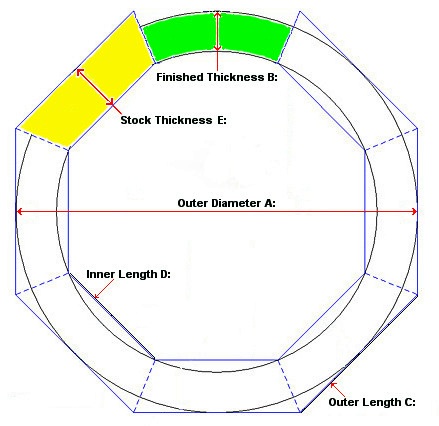

Next thing is how best to cut the wooden segments to make bowls. I am supposing a good quality small accurate table saw would do the trick? maybe in conjunction with some kind of jig.

Could anyone advise me on this? eg is this the way to go and what is a suitable saw. my own (a Ryobi 315mm blade) is well worn and only really accurate enough for farm building construction.

Rang Aminster today and they will have the lathes i want to see in store for me in November.

Next thing is how best to cut the wooden segments to make bowls. I am supposing a good quality small accurate table saw would do the trick? maybe in conjunction with some kind of jig.

Could anyone advise me on this? eg is this the way to go and what is a suitable saw. my own (a Ryobi 315mm blade) is well worn and only really accurate enough for farm building construction.

<<<< Link

<<<< Link