You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WOW !!! my 1st propper Table Saw : ) :) :)

- Thread starter Tusses

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Steve Maskery

Established Member

Yep, nice saw, excellent refurb job. But inadequate guard and badly adjusted riving knife. You need a 10" blade for a 10" saw, that should cure the latter.

The problem with a crown guard like that is that it only prevent contact from above (such as you falling over onto it) it does little to prevent you sticking your fingers in there. But I think we are having this conversation on another thread anyway.

Nice job, I'm sure she'll serve you well. I've just refurbed a Meddings drill of 1962 vintage and am very pleased with it.

Cheers

Steve

The problem with a crown guard like that is that it only prevent contact from above (such as you falling over onto it) it does little to prevent you sticking your fingers in there. But I think we are having this conversation on another thread anyway.

Nice job, I'm sure she'll serve you well. I've just refurbed a Meddings drill of 1962 vintage and am very pleased with it.

Cheers

Steve

OPJ

Established Member

Looks like you got yourself a great deal there; hope you enjoy it!

With regards to the setting of the riving knife, the current HSE regs. require that the riving knife is no more than 8mm away from the back of the blade, at bed level.

If you plan to use the saw for cross-cutting then, not only will you need to consider your choice of blade but I'm sure you'll also find a home-made sled makes the work more accurate than a tiny mitre gauge.

With regards to the setting of the riving knife, the current HSE regs. require that the riving knife is no more than 8mm away from the back of the blade, at bed level.

If you plan to use the saw for cross-cutting then, not only will you need to consider your choice of blade but I'm sure you'll also find a home-made sled makes the work more accurate than a tiny mitre gauge.

BradNaylor

Established Member

- Joined

- 17 Oct 2007

- Messages

- 2,311

- Reaction score

- 2

You did well to find a single phase machine at that price, and you've done a great job cleaning it up.

As far as blades are concerned, your local saw doctor will be able to sort you out with 10" blades with the the correct bore. You would be amazed how many of his customers will be using identical saws. I would go for a couple of blades for ripping and a couple for cross cutting. You need two of each so that you've got one on the machine while the other is being sharpened. Look up 'Saw Sharpening Services' in Yellow Pages and get pally with your local saw doctor.

The correct sized blade should sort out the riving knife gap. If not, get a new knife made. Any blacksmith or small engineering shop will be able to make you one to your template. The last time I got one made it cost me £20 (cash job). Your saw doctor will be able to suggest someone if he can't do it himself.

A plywood cross-cut sled that runs in the mitre slot would be well worth making, as would an out-feed table behind the saw to support long lengths of timber as you cut them. In most workshops this doubles up as a work table.

Enjoy your saw!

Cheers

Dan

As far as blades are concerned, your local saw doctor will be able to sort you out with 10" blades with the the correct bore. You would be amazed how many of his customers will be using identical saws. I would go for a couple of blades for ripping and a couple for cross cutting. You need two of each so that you've got one on the machine while the other is being sharpened. Look up 'Saw Sharpening Services' in Yellow Pages and get pally with your local saw doctor.

The correct sized blade should sort out the riving knife gap. If not, get a new knife made. Any blacksmith or small engineering shop will be able to make you one to your template. The last time I got one made it cost me £20 (cash job). Your saw doctor will be able to suggest someone if he can't do it himself.

A plywood cross-cut sled that runs in the mitre slot would be well worth making, as would an out-feed table behind the saw to support long lengths of timber as you cut them. In most workshops this doubles up as a work table.

Enjoy your saw!

Cheers

Dan

ok - here we go ....

thanks for all the comments.

I will be making a sliding bed for cross cutting, along with other jigs and fixtures that I have made over the years for my old TS, as they dont fit this one .

I have made an insert - which will accommodate the knife/splitter - is mine a knife or splitter - and whats the difference ?

I can tilt the knife forwards a little which does close up the gap..

BUT !!!! all that goes out the window when I lower the blade :?

this is a pic looking at the knife mounting bolts

anyone been in this situation and come up with a workable solution ?

picking up on a few other comments - Saw Doctor ? is this a generic name of and blade sharpener or is there a franchise called the Saw Doctor ?

I have a stack of blades that came with the saw - all approx 9". there are cross cut - rip - rough - fine etc etc so I would like to keep them if poss . They are all old school ones that will need sharpening from time to time - one of them is an original Wadkin

I can make a new knife - but, as above ... is there any point if it doesnt raise and lower with the blade ?

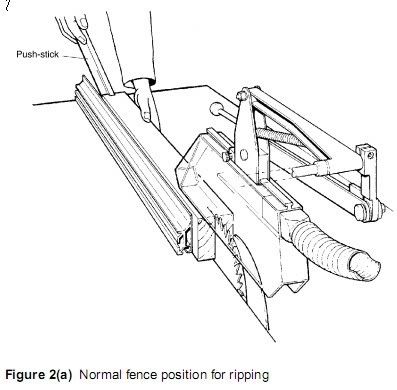

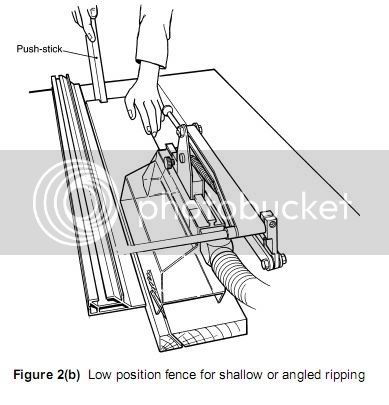

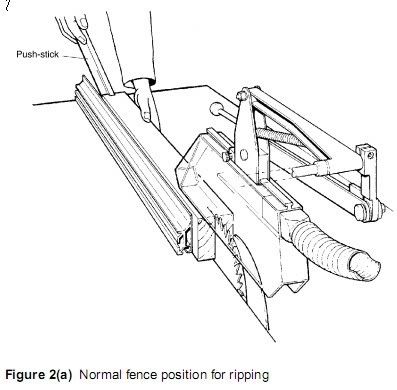

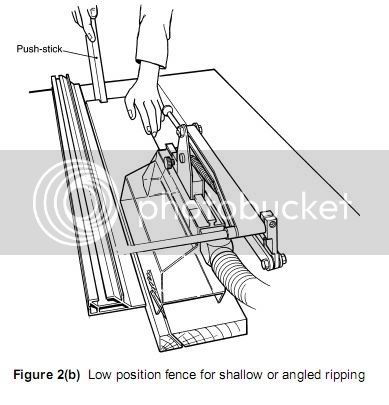

Fence ... I can understand short but not low ... what is the advantage of a low fence (this one may have been on the other thread - but I'll stick it here for now)

oh ... and as for spraying / painting it - I'm thinking about leaving it. I have this thing about 'patina' ! and looking at something and seeing its history / imagining all the things it has made !

thanks for all the comments.

I will be making a sliding bed for cross cutting, along with other jigs and fixtures that I have made over the years for my old TS, as they dont fit this one .

I have made an insert - which will accommodate the knife/splitter - is mine a knife or splitter - and whats the difference ?

I can tilt the knife forwards a little which does close up the gap..

BUT !!!! all that goes out the window when I lower the blade :?

this is a pic looking at the knife mounting bolts

anyone been in this situation and come up with a workable solution ?

picking up on a few other comments - Saw Doctor ? is this a generic name of and blade sharpener or is there a franchise called the Saw Doctor ?

I have a stack of blades that came with the saw - all approx 9". there are cross cut - rip - rough - fine etc etc so I would like to keep them if poss . They are all old school ones that will need sharpening from time to time - one of them is an original Wadkin

I can make a new knife - but, as above ... is there any point if it doesnt raise and lower with the blade ?

Fence ... I can understand short but not low ... what is the advantage of a low fence (this one may have been on the other thread - but I'll stick it here for now)

oh ... and as for spraying / painting it - I'm thinking about leaving it. I have this thing about 'patina' ! and looking at something and seeing its history / imagining all the things it has made !

pe2dave

Established Member

Tusses":g7j32ash said:Fence ... I can understand short but not low ... what is the advantage of a low fence (this one may have been on the other thread - but I'll stick it here for now)

One view is safety? Only needs a knot to grab the wood and your hand

will be whipped away pretty smartish. Also a lot easier to use a piece of

ply, an oak batten sliding in the mitre slot, a piece at right angles across

the back of the ply to act as a backstop. Easier to use, safer and generally

just as accurate.

HTH

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

superunknown

Established Member

I have the same problem as you with the riving knife not lowering with the blade. On later models of the 10AGS this is not an issue, they changed the design. I'm not sure there is a solution to this.

Hi Tusses

First I would like to congratulate you for your "new" saw and the wonderful renovating job.

I'm sure that the iron table top is better then my Aluminum top...

The difference between Splitter and Riving knife is very simple; A riving knife is set to 3~8mm (1/8"~5/16"...in case that you are "Imperial" ) and it moves up/down and tilts together with the blade while keeping the 3mm behind the blade at any blade height.

) and it moves up/down and tilts together with the blade while keeping the 3mm behind the blade at any blade height.

You can say that the blade and the riving knife are like "one unit" that moves up/down and tilt.

In your case, it looks to me like a splitter and only when the blade is at "full up" position you get a "Riving knife".

About the "Low fence", as I said in the other post, I tried it ones and never got back to "High fence"...just imagine that you are ripping without having any rip fence...everything is open and it's very easy to put a push stick or a push block/shoe....

Unfortunately, we must have some guide that keeps the workpiece at the required distance and always parallel to the blade so...we must use a rip fence...

But, make an experiment...set the fence to 1" from the blade and rip some board...first time with the "High fence" and second time, with "Low fence" and decide for yourself with which fence is easier to control.

Even if I cut a 2" thick material, I use the "Low fence"....

That's what the SHE has to say about.....

In my opinion, the high fence is used only when cutting narrow and high boards (kind of re-sawing), if the board is wide the low fence will do the same.

Another advantage of the "Low fence" is when you tilt the blade for bevel cut...if the cut piece is narrow, the tilted blade can touch the "High fence" but will not, with "Low fence"...as you can see on the drawing above and the picture below...

Regards

niki

First I would like to congratulate you for your "new" saw and the wonderful renovating job.

I'm sure that the iron table top is better then my Aluminum top...

The difference between Splitter and Riving knife is very simple; A riving knife is set to 3~8mm (1/8"~5/16"...in case that you are "Imperial"

You can say that the blade and the riving knife are like "one unit" that moves up/down and tilt.

In your case, it looks to me like a splitter and only when the blade is at "full up" position you get a "Riving knife".

About the "Low fence", as I said in the other post, I tried it ones and never got back to "High fence"...just imagine that you are ripping without having any rip fence...everything is open and it's very easy to put a push stick or a push block/shoe....

Unfortunately, we must have some guide that keeps the workpiece at the required distance and always parallel to the blade so...we must use a rip fence...

But, make an experiment...set the fence to 1" from the blade and rip some board...first time with the "High fence" and second time, with "Low fence" and decide for yourself with which fence is easier to control.

Even if I cut a 2" thick material, I use the "Low fence"....

That's what the SHE has to say about.....

In my opinion, the high fence is used only when cutting narrow and high boards (kind of re-sawing), if the board is wide the low fence will do the same.

Another advantage of the "Low fence" is when you tilt the blade for bevel cut...if the cut piece is narrow, the tilted blade can touch the "High fence" but will not, with "Low fence"...as you can see on the drawing above and the picture below...

Regards

niki

Ian Mellin

Established Member

Hello I'm new to this site I have an old ags10, but am missing the parts that connect the riving knife to the saw could someone please supply me with exact measurements so I can get one made.

Kind regards

Ian

Kind regards

Ian

MattRoberts

Established Member

Wow, this is a 6 year old thread

DiscoStu

Established Member

Welcome Ian, whilst Matt seems surprised that this thread has been resurrected I commend you for searching before posting - I rarely do that! I can't help with your question but hopefully someone will be able to.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

SammyQ

Established Member

Ian, there are a few of us here with AGS's. Can you make your query more explicit please so that we may help you? Dalton's have a manual on their website with a manual/parts diagram, so that you can spell out to us what you need. AGS parts are hens' teeth, but they DO crop up on Ebay. There are also several AGS-based threads here and on Woodhaven 2.

Sam

Sam

Ian Mellin

Established Member

Sam,

I've downloaded the manual for the AGS10, if I look at other posts I've found about this subject e.g the post by Katellwood the part they have photographed looks like it would fit my machine. The serial no of my machine is 78606 it is metric. I have also seen there are several different flavours of the AGS10 so not really sure which way to go with this one.

Thanks

Ian.

I've downloaded the manual for the AGS10, if I look at other posts I've found about this subject e.g the post by Katellwood the part they have photographed looks like it would fit my machine. The serial no of my machine is 78606 it is metric. I have also seen there are several different flavours of the AGS10 so not really sure which way to go with this one.

Thanks

Ian.

SammyQ

Established Member

Yes Ian, there are two arrangements to be sure. Earlier BSW-based machines (like mine) had a plate that was broad and flat, perforated with slots and mounted the riving knife off it. Later, metric-based ones seem to have a narrower plate attached to the same place on the arbour casting, with a slightly different mechanism.

I can't see Katellwood's here in work 'cos of spam/**** filters, but I'll try tonight at home to get you a pikkie of mine.

From memory, Mr Fish was really good to me and posted pictures of his later model here some years ago.

Sam

PS Wallace has a list of serial numbers vs dates on his site: http://www.wadkinrestorations.co.uk/wad ... ating.html

Sam

I can't see Katellwood's here in work 'cos of spam/**** filters, but I'll try tonight at home to get you a pikkie of mine.

From memory, Mr Fish was really good to me and posted pictures of his later model here some years ago.

Sam

PS Wallace has a list of serial numbers vs dates on his site: http://www.wadkinrestorations.co.uk/wad ... ating.html

Sam

Ian Mellin

Established Member

Sam,. I looked at the master fish posts very useful, I'd also got an enquiry going at Wadkin themselves they identified exactly the same parts as the manual that was posted, so I've asked them to quote me I can then saw away safely. Thanks for the pointers much appreciated.

Regards

Ian.

Regards

Ian.

SammyQ

Established Member

Benchwayze

Established Member

On blowing up the image it looks like 1028 to me Sammy, unless it's my eyes!

Trying to be helpful

Trying to be helpful

SammyQ

Established Member

Thanks John; I went back to the original jpeg and it's defanintootly 1026!

Let's see if it's even what the OP needs?

Sam

Let's see if it's even what the OP needs?

Sam

I'm always surprised how machinery, even pieces that are many hundred pounds come with miter slots and fences that don't fit properly.

Is it really that difficult to match two pieces? =s I wouldn't have thought so. Although to be honest i'd rather they did put the money on things which I can't fix relatively easily myself.

Is it really that difficult to match two pieces? =s I wouldn't have thought so. Although to be honest i'd rather they did put the money on things which I can't fix relatively easily myself.

Similar threads

- Replies

- 13

- Views

- 3K