joiner_sim

Established Member

This project wasn't really planned at all. It has started from me practising how to cut dovetails by hand. Here's my first attempt on friday, which you can see went dreadfully wrong! However, it did teach me the basics and with a little bit of help from some of the guys off UK Workshop Forums, the rest of the project came alive today.

Following the advice, I am working with African Cedar which is a hardwood, which are apparently better to work with when cutting dovetails, and it was so true! Here's my first attempt:

As you can see, I think it's an immediate improvement over the first attempt in softwood. Having the hardwood to spare I decided to have a go at doing another 3 joints to try and make a box. So here's the second joint I cut. This time I nearly cut out the wrong part of the dovetails, as you can see, luckily I stopped cutting before I did the damage though!

My third attempt, getting better, and faster!

The fourth and final joint is cut and I actually have got a box!

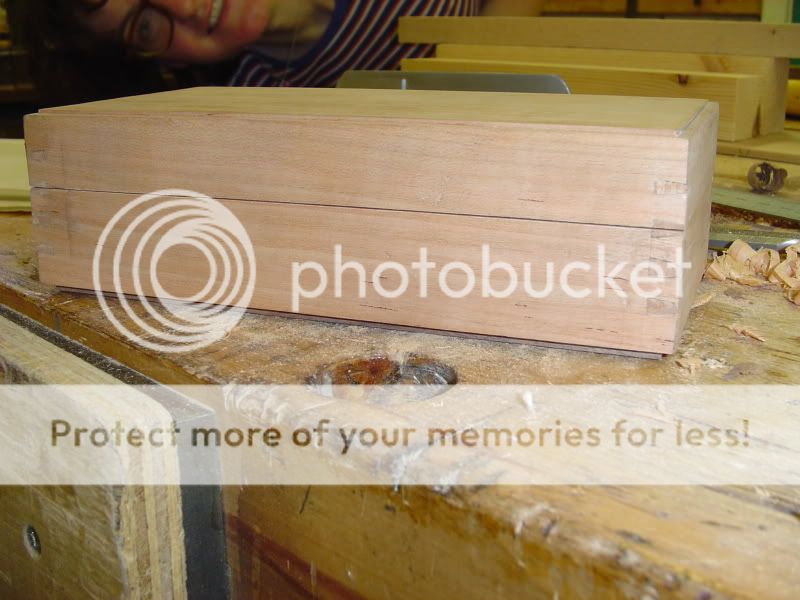

And here is it dry assembled!

Being fairly pleased with myself, I got to work on planning out a lid and base. I routered the bottom edges of the box so I can fit a base after it has been glued up. As you can see in the photo, it is routered and cramped up.

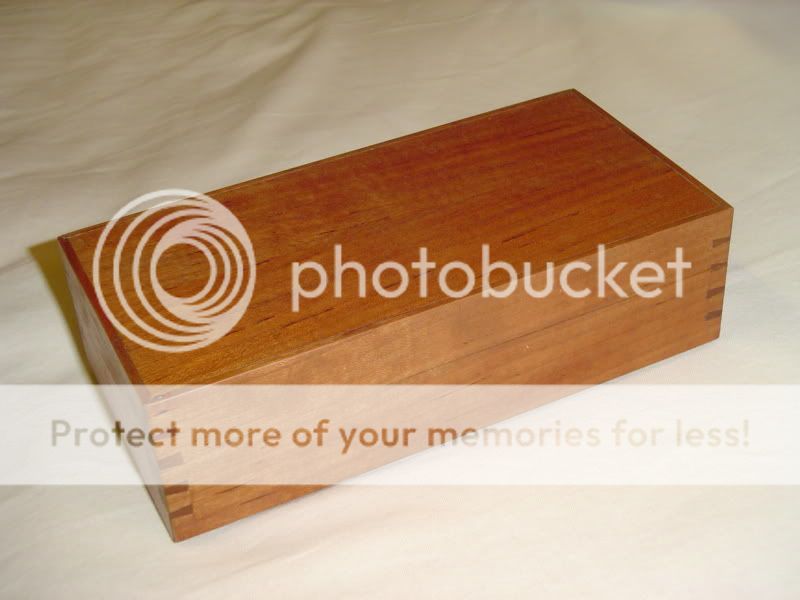

Below, is the lid and base. The base is the same timber as the box, african cedar. The lid is sapele. The main reason for the change of timber is down to the fact it's all I had left lying around, but I think it will give a nice contrast between the two timbers. As you can see I'm dowel joint the two pieces together.

I finished off todays work by glueing and sash clamping the lid and base parts together.

I hope you have enjoyed reading the progress so far, this was more of an experiment in my hand skills and I think it's paid off, I never thought I'd of even contemplated putting a base and lid on the thing. Please let me know what you think of it so far, thankyou, -Simon.

Following the advice, I am working with African Cedar which is a hardwood, which are apparently better to work with when cutting dovetails, and it was so true! Here's my first attempt:

As you can see, I think it's an immediate improvement over the first attempt in softwood. Having the hardwood to spare I decided to have a go at doing another 3 joints to try and make a box. So here's the second joint I cut. This time I nearly cut out the wrong part of the dovetails, as you can see, luckily I stopped cutting before I did the damage though!

My third attempt, getting better, and faster!

The fourth and final joint is cut and I actually have got a box!

And here is it dry assembled!

Being fairly pleased with myself, I got to work on planning out a lid and base. I routered the bottom edges of the box so I can fit a base after it has been glued up. As you can see in the photo, it is routered and cramped up.

Below, is the lid and base. The base is the same timber as the box, african cedar. The lid is sapele. The main reason for the change of timber is down to the fact it's all I had left lying around, but I think it will give a nice contrast between the two timbers. As you can see I'm dowel joint the two pieces together.

I finished off todays work by glueing and sash clamping the lid and base parts together.

I hope you have enjoyed reading the progress so far, this was more of an experiment in my hand skills and I think it's paid off, I never thought I'd of even contemplated putting a base and lid on the thing. Please let me know what you think of it so far, thankyou, -Simon.