maltrout512

Established Member

As I mentioned in my comp entry I had decided on making a writing slope keeping to a traditional theme/stile. So far I have spent a little time on working out what size it will end up. So it will be about 380mm wide, 220mm deep and 180mm tall. These measurements are when it is in the closed position.

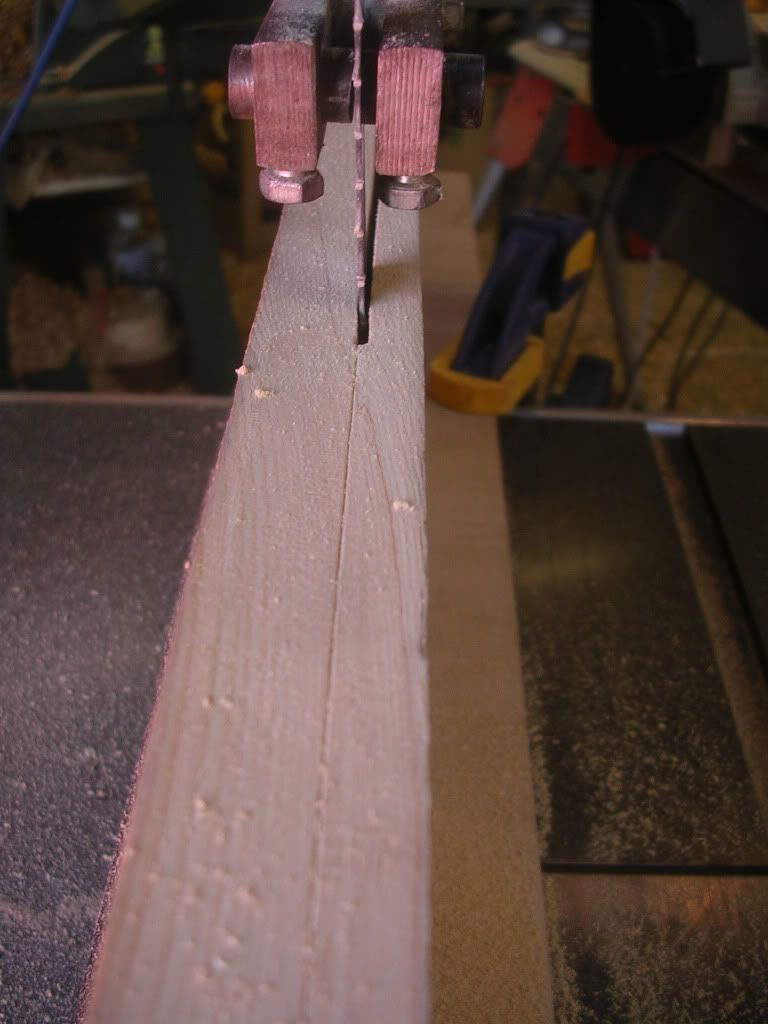

Wednesday I bought some cedar lebanon. 1700mm, 500mm, 27mm.

What a nice smell when working it.

Here is the plank.

This is at the moment as far as I have reached. Still mulling over what vernier to use, what type of material for banding/stringing and so on. Hope to spend some time on it over the weekend.

Wednesday I bought some cedar lebanon. 1700mm, 500mm, 27mm.

What a nice smell when working it.

Here is the plank.

This is at the moment as far as I have reached. Still mulling over what vernier to use, what type of material for banding/stringing and so on. Hope to spend some time on it over the weekend.