1. BU or BD makes no difference for the wood. The wood only cares about the iron where it actually touches the iron. How far back from the edge does the wood touch the iron? 1mm? Maybe it slightly glides over the iron at 2mm from the edge? Any further the shaving curls away from the edge, and the cut surface dwindels back behind the edge. For the wood, the bevel orientation is just semantics.

2. The only difference for the wood is the cutting angle. 45 degree in a standard BD plane. 45 degrees in a BU plane with a 33 degree bevel. Exactly the same.

Hi Kees

OK, this is easier to explain - still theoretical, but hopefully someone qualified can interpret my thoughts and support or reject the notion.

Firstly, none of the above is relevant. Misses the point completely (as you will hopefully recognise in a short while). I'm not dismissing what you have written, just that it does not relate to the issue of Centre of Effort.

Both BU and BD planes plane wood. The wood cannot determine if they are BU or BD. Ignore cutting angles. Tis is also irrelevant in this topic. The wood cannot tell if the cutting angle comes from a B or BD plane.

The issue of C of E is not what happens on or to the wood. It is about what happens to the user of the plane. It is the experience the planer has when using a BD or BU plane. It is not just these planes, but the experience of planing when the hang of the handle is changed, when the handle is raised or the body is lowered.

4. You say that you compared BU versus BD in your shooting board test. But you don't mention that you also compared high versus low cutting angle in the exact same experiment. An experiment with two variables at the same time. So you cannot conclude that the bevel orientation was the major cause for the differences in wear. Because the wood doesn't know about the bevel orientation of the plane, you can just as well conclude that the cutting angle was the major cause.

I did compare BU and BD in the shooting plane review. And I compared low verses high beds. And I compared different bevel angles.

Of course you can draw conclusions (about BU and BD) with multiple variables involved - I am a trained researcher (as well as a clinician), and controlling variables is bread-and-butter to me. There was absolutely no doubt that the BD orientation, with the blade bedded at 45 degrees, created greater force on the edge of the blade than did the blade in the BU orientation, which was bedded at 12 degrees.

You have perhaps only read the one review. There was a second, a follow up. Look at the conclusions.

Link:

http://www.inthewoodshop.com/ToolReview ... lades.html

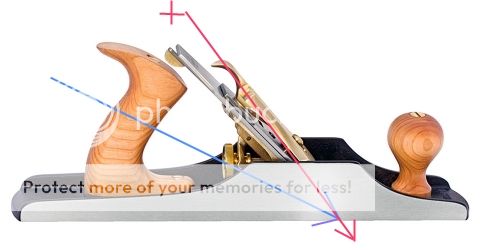

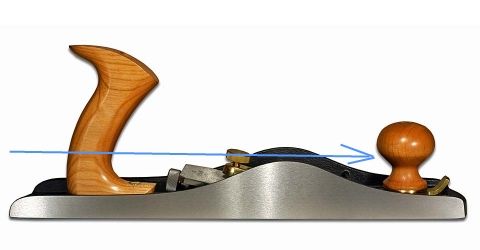

5. Look at these two planes. Bearing in mind the points discussed above, what differences do we see? Exactly what difference in the planes make them feel different?

Image

Image

The rear handle is a little bit more upright in the BU plane, and it is positioned a little bit more to the rear. The BU plane has a four finger grip versus 3 finger grip of the BD plane. And the center of gravity is lower in the BU plane. And now I am curious which one of these details make a real difference in the experience of using the plane.

Thank for these pics, Kees. These again allow me to show you what I have been referring to all along.

What you will see below are vector lines. The single blue line represents the Centre of Effort, and the red line is where this is increased.

Please keep in mind that I am just theorising. I am trying to find a way to both convey what I have observed for some years and translate it into something that may be explained scientifically. Vectors and engineering are not my area of expertise (and it shows!). However, I recognise that if we can understand what is happening here, it may just contribute to plane design ergonomics.

There must be a reason why pushing horizontally (with the more upright handle on the BU) creates less resistance than pushing down (with the more forward leaning BD handle)

Look at this picture of the BD plane ...

When you push down on a forward leaning handle, you direct weight over the mouth. If you raise the hand (handle) higher, the weight is increased, and resistance increases with it. (Keep in mind that both BD and BD also place pressure on the front knob. For the argument, let us just assume that this is the same for both planes).

Here is the BU plane with the more upright handle ...

Now the weight is lifted off the mouth. Of course, if you add a handle with more forward lean, then you increase the weight over the mouth, and thereby increase resistance.

I experienced this when I changed the handles on my LV planes from the original to Bailey-style.

Keep in mind that there is also the angle of the bed to take into account. From my earlier experiments, the lower bed exerts less force on the edge of the blade, and the higher bed exerts greater force on the edge of the blade.

The combination of lower C of E and lowered force combines to make the BU plane feel lighter in the hand as if it were "floating". Conversely, the increased resistance when pushing the BD plane makes it feel more "powerful".

These are features that are part of the ergonomics of plane use. They do not directly change the way the plane impacts on the wood.

Regards from Perth

Derek