novocaine

Established Member

pick and choose Beau, you take your moisture meter with you and you pick the best of the 3 pallets they tend to have in. it pisses the staff off but it is what it is. You look at the ends and take the tight grain and if possible the least amount of pith, then sort that by number of knots and shakes and finally straightness.

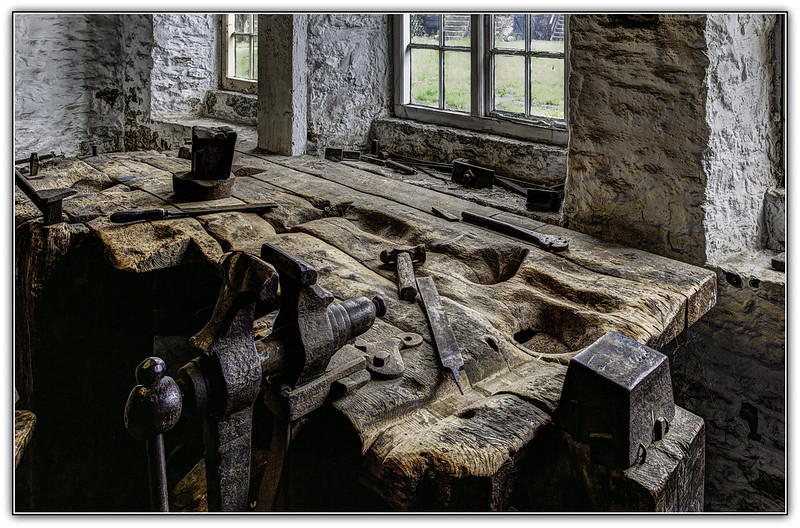

I'd rather have a softwood bench top over a hardwood bench any day, if I drop a piece, it marrs the bench, not the piece, I don't have to be careful around the bench and when it dies I can drill out the fox wedge on the through tenon and make a new top. the entire bench cost me less than 50 quid. it's been a year plus since it was built and it's not showing any real signs of death, it has a sheet of MDF over one end to over some protection next to the metal vice (as much as I intend to do in terms of protection), the lower rails are bowed because of the stuff I've stacked on them, the top hasn't moved more than seasonal allowance.

didn't put much effort in to planning the legs, why when no one can see them and they are completely functional?

The bench by David Rees, on Flickr

The bench by David Rees, on Flickr

I'd rather have a softwood bench top over a hardwood bench any day, if I drop a piece, it marrs the bench, not the piece, I don't have to be careful around the bench and when it dies I can drill out the fox wedge on the through tenon and make a new top. the entire bench cost me less than 50 quid. it's been a year plus since it was built and it's not showing any real signs of death, it has a sheet of MDF over one end to over some protection next to the metal vice (as much as I intend to do in terms of protection), the lower rails are bowed because of the stuff I've stacked on them, the top hasn't moved more than seasonal allowance.

didn't put much effort in to planning the legs, why when no one can see them and they are completely functional?

The bench by David Rees, on Flickr

The bench by David Rees, on Flickr