If you like the Sorby then you're better off with the SC4 because it takes exactly the same jaws but has two advantages: Firstly its cheaper and secondly the Record Power SC range has wider than normal jaw carriers which makes for a more sturdy (less vibration) work holding solution.

The SC range was only launched year before last and it's therefore learned many of the lessons and pitfalls from those which came before it. Specifically, Record Power used to market the Nova range from Teknatool and when they designed the SC range, they specifically overcame all the shortcomings of the Nova chucks, notably the jaws tighten with a clockwise turn as you would expect intuitively and as I've said, the fatter jaw carriers. Other than that they're basically a total rip off of the Nova chucks....but cheaper and better.

Personally my chuck journey has followed the evolving work holding needs and my advice would be to start with an all rounder because if you do really take to it, it's inevitable as night follows day that you will buy more chucks. Thus it makes sense to get an all rounder and for that reason my personal choice would be to buy into a given manufacturer and then stick to them because you're buying into a jaw compatibility universe.

So I would plump for either the Axy range because in my view their engineering standards are far higher than anything made in the Far East or the RP SC4 because although manufactured in the Far East they are designed in the UK and quality control is good. Plus all the reasons about fatter jaw carriers etc.

But for sheer out and out quality, it's not possible to better the Axminster range, those stainless steel bodies are very appealing because they don't rust and that's a biggy with chucks in the main. They are more expensive but you really do notice that superior quality.

This advice comes from the following journey:

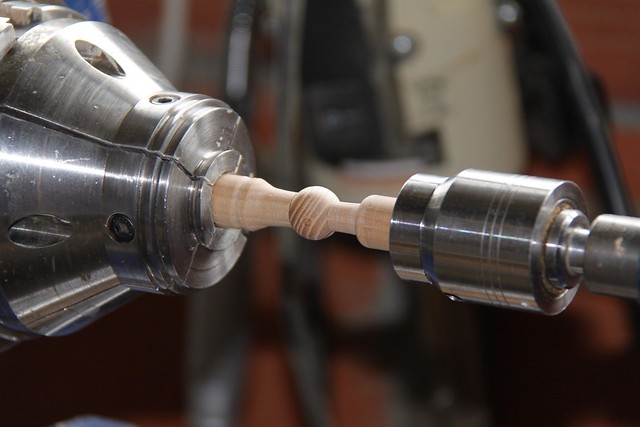

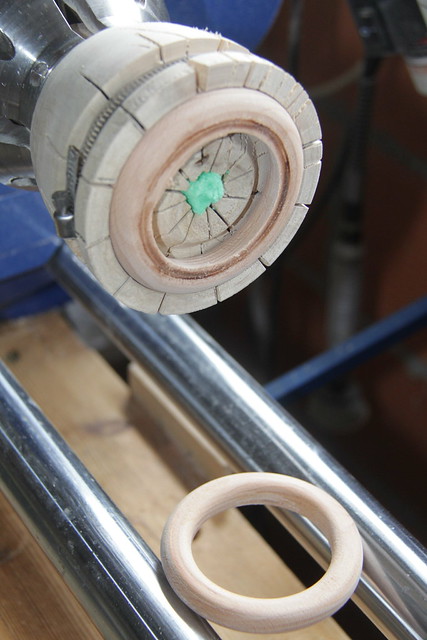

Started with a Supernova 2 with various different jaws. Got bored changing jaw sets so bought a second compatible chuck cheap from Rutlands one Easter, the 4" Dakota model. That ended up with the Nova cole jaws permanently attached and then I had a near miss with a big hollow form blank so wanted a bigger solution. I ended up buying the new(ish) Axy Evolution at £180 which is the best chuck I've ever used in terms of concentricity and build quality. it's a joy to use and huge so great for big, heavy, out of true work. Then I wanted a tiny weeny chuck for holding apple stems and finials etc so I bought the RP2000 with the pin jaws. Finally out of pure curiosity of the new SC range from RP, I bought (just this May) the SC3 for smaller spindle work. I really like it as a general use, for smaller stuff, lightweight solution that's directly threaded M33 for my lathe.

So I have tried a few across the manufacturers and the Axy is the king for build quality but of course is the most expensive. I think your greatest decision is which manufacturer family to buy into because Axy and all the others aren't cross compatible whereas the Sorby/Nova/SC range are all cross compatible.

If I had my time again I would probably buy all Axy....but only if I had the money....and I'd still but the RP2000 cos its just so lovely