wallace

Established Member

cheers Van, I've got one sorted a bit closer to home. I got Matt Matts drawings but i thought the real thing would be easier to copy.

Westwood":3ezh1ips said:Very impressive restoration so far. looking forward to seeing the finished article and a good mug shot.

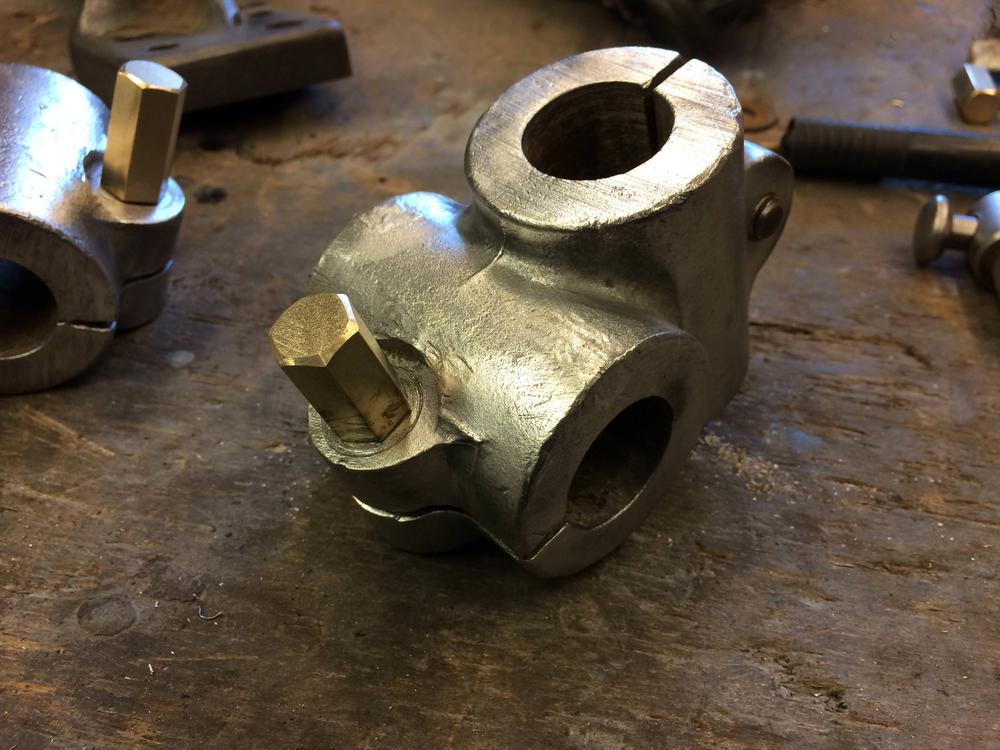

wallace":2ayrlg9r said:I had a rummage around my junk piles and found these which I'm going to try and make into a crown guard and support.

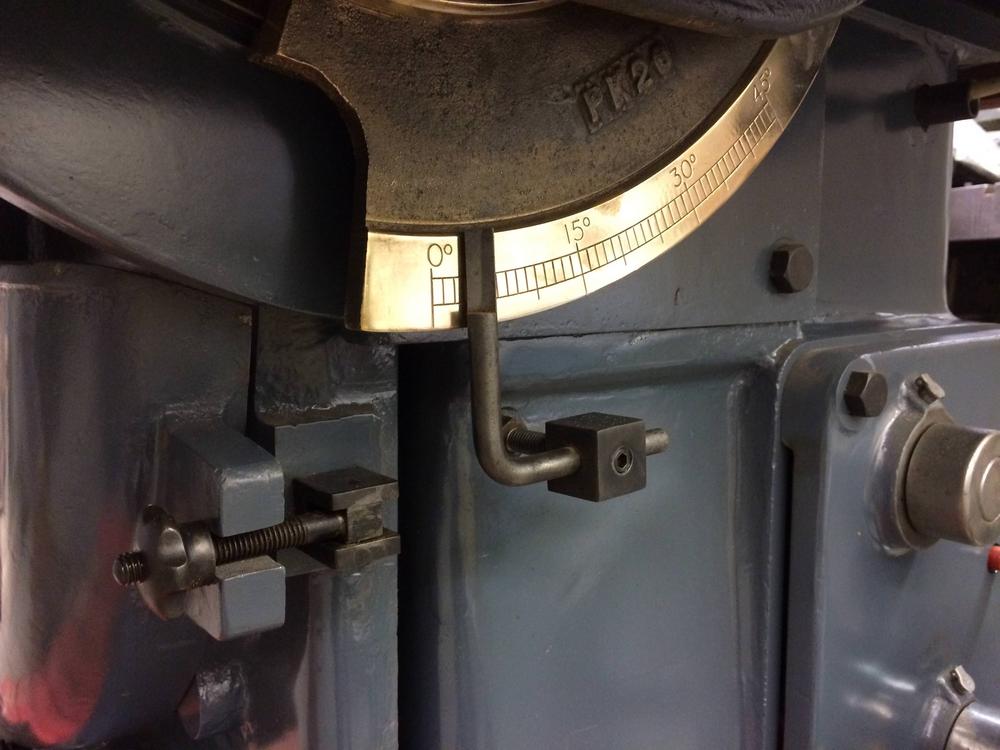

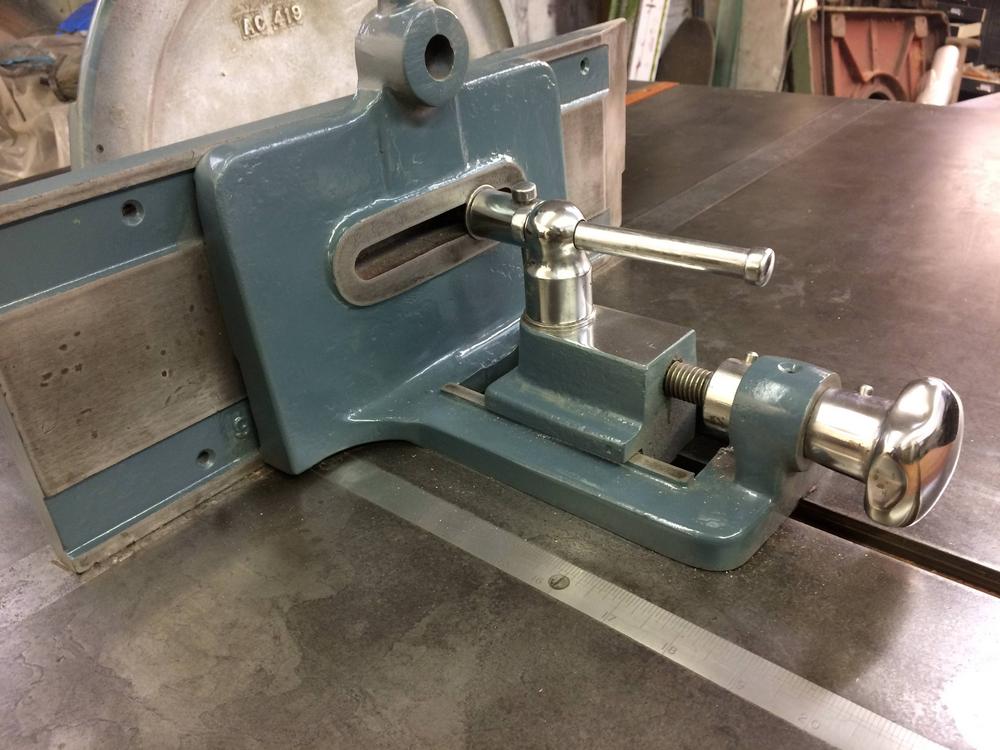

That hand screw Knob is paramount. You can't mistake a Wadkin Spindle Moulder split fence. Brilliant use as a substitute rip fence. Tonymore done, I'm pleased the motor was ok after spending 4 years outside. Bearings in good shape so just flushed and repacked.

After much filling and sanding a few coats of primer

Followed by the usual RAL 7011 enamel

Theres no reason to paint inside other than it looks good

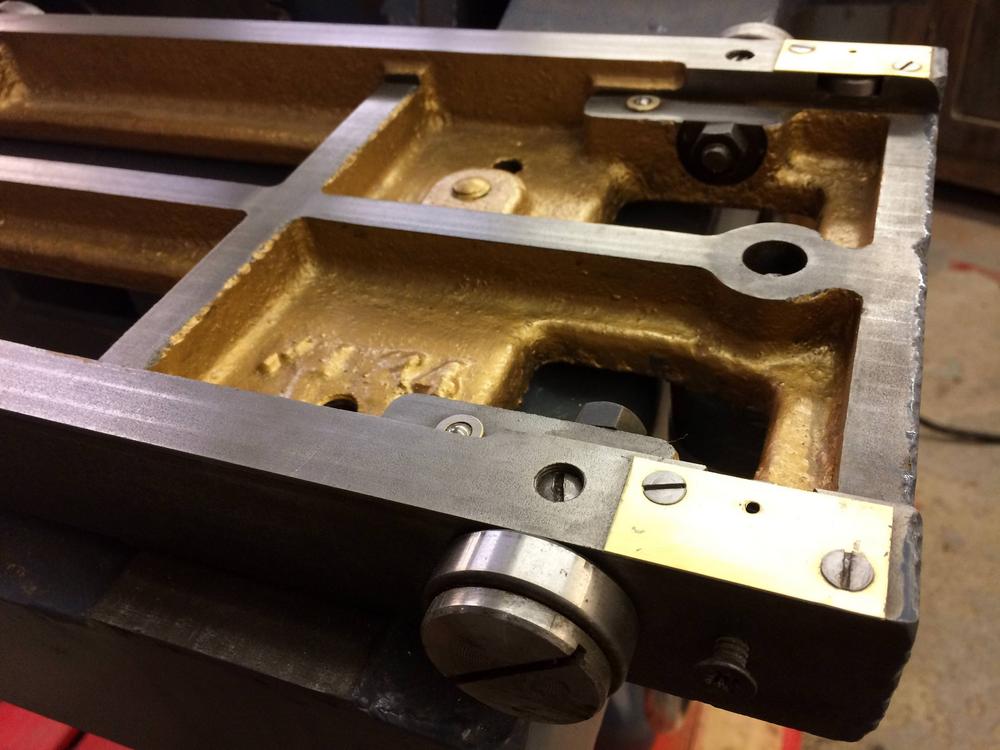

This saw was missing its fence, its original fence ended up in canada. I've been looking for a fence for years so in the end I got the fence off a EQ spindle moulder which has the same fine adjuster but it doesnt tilt. I think it should work well and I think the provision to use the EQ's hold downs which go into the top of the fence will be quite usefull.

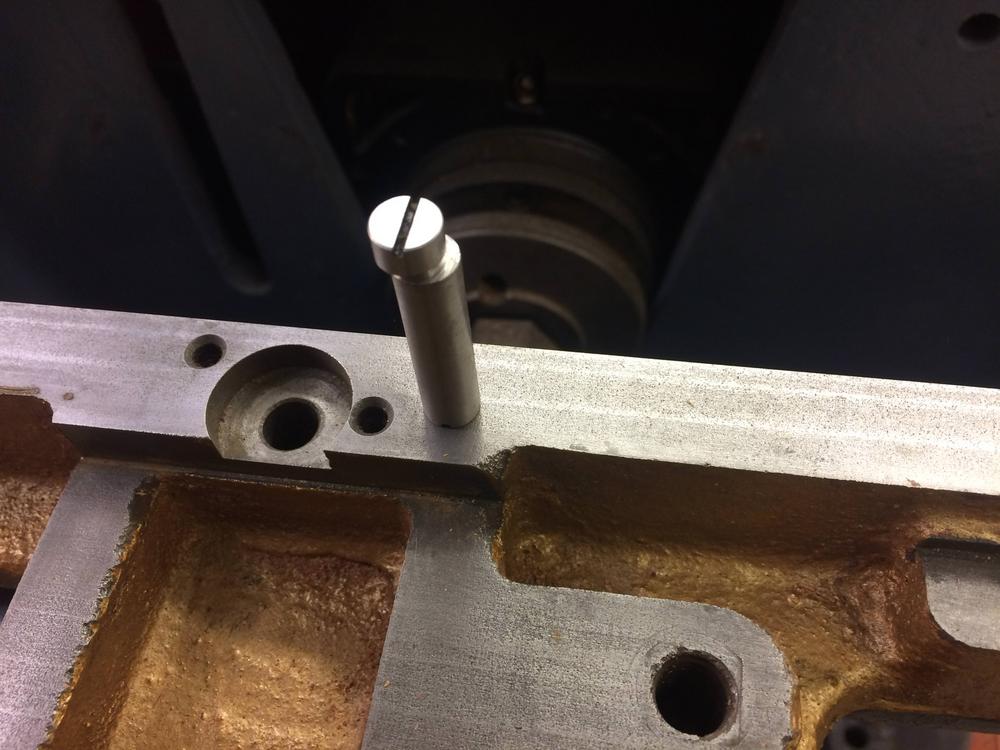

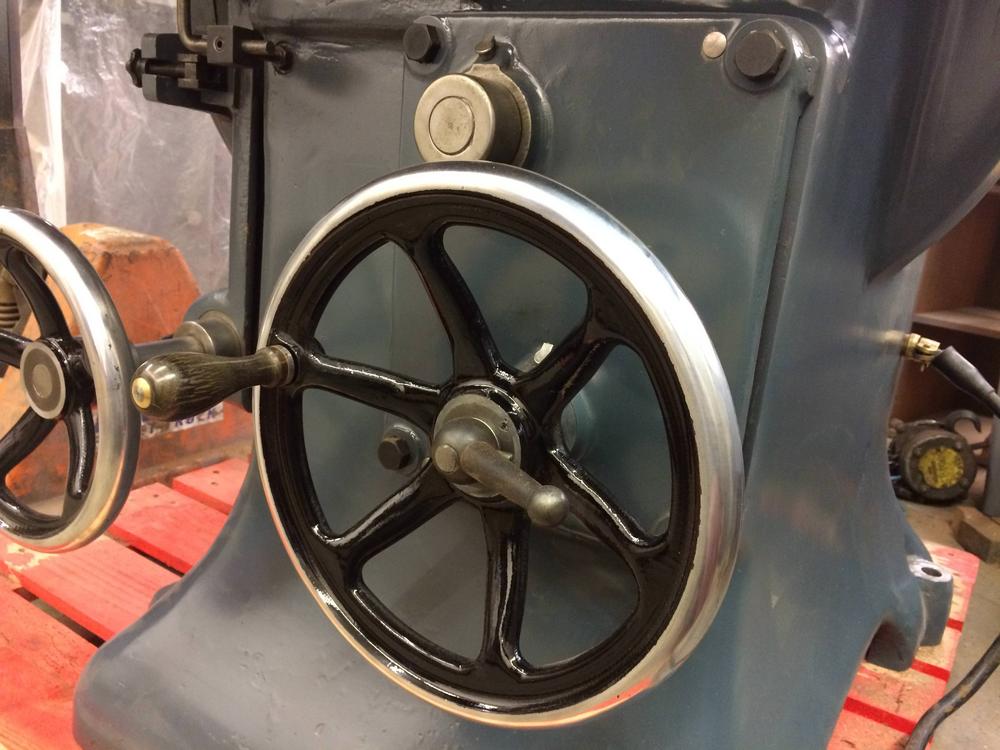

Thanks for the great thread! I was wondering, after removing the horn handles, how you put them back in? I would think there wouldn’t be enough material left to re-peen it? Thanks!More done, to remove he handle from the handwheel is pretty easy, just drill the peened over end a bit and knock it out.

The handles look a bit rough but since they are made from horn they clean up really easy. Stick the stub in a drill, hold some sandpaper and spin it in your hand, go through the grits and finish with t-cut

The handwheels are in great shape and just needed putting in the lathe and used grey then red scotchbrite before polishing.

This machine looked in bad order but the more I dig into its obvious it was well cared for.

I tried gun bluing for blackening some bolt heads

And just a little bling