JonnyD

Established Member

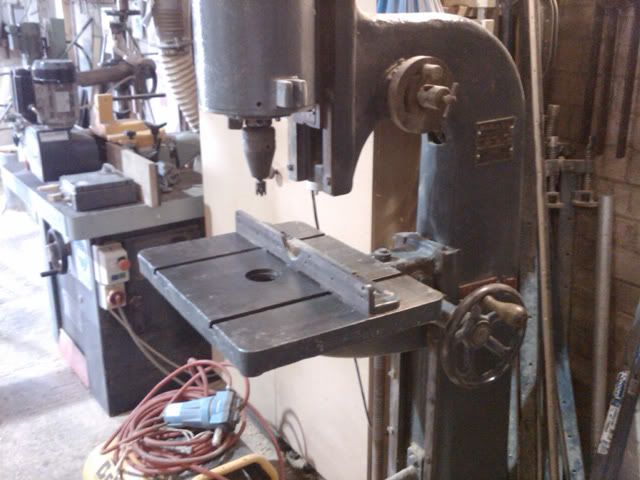

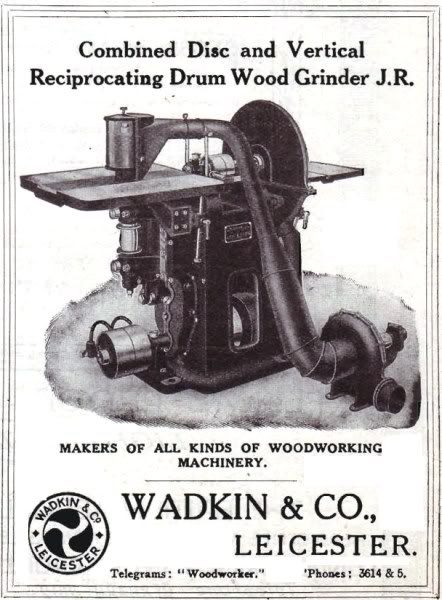

Its a great machine. Mine was in pretty good nick when i got it but i am tempted to pimp it just never seem to get the time. looking at Jacks brochure pics which ive never been able to find the fence on mine is original too.

cheers

Jon

cheers

Jon