wallace

Established Member

I've been pretty busy doing lathes this year, I've done 4 but since I already did a thread on one I thought it pointless to do another thread. I'm now doing an morticer which I've never done before so looking forward to it.

I bought this about 3 years ago thinking it might have some good parts to salvage, but instead I'm going to try and resurrect it. Before I got it it had spent some time outside and since in my possession its sat out side smothered in waxoyle and covered with a tarp.

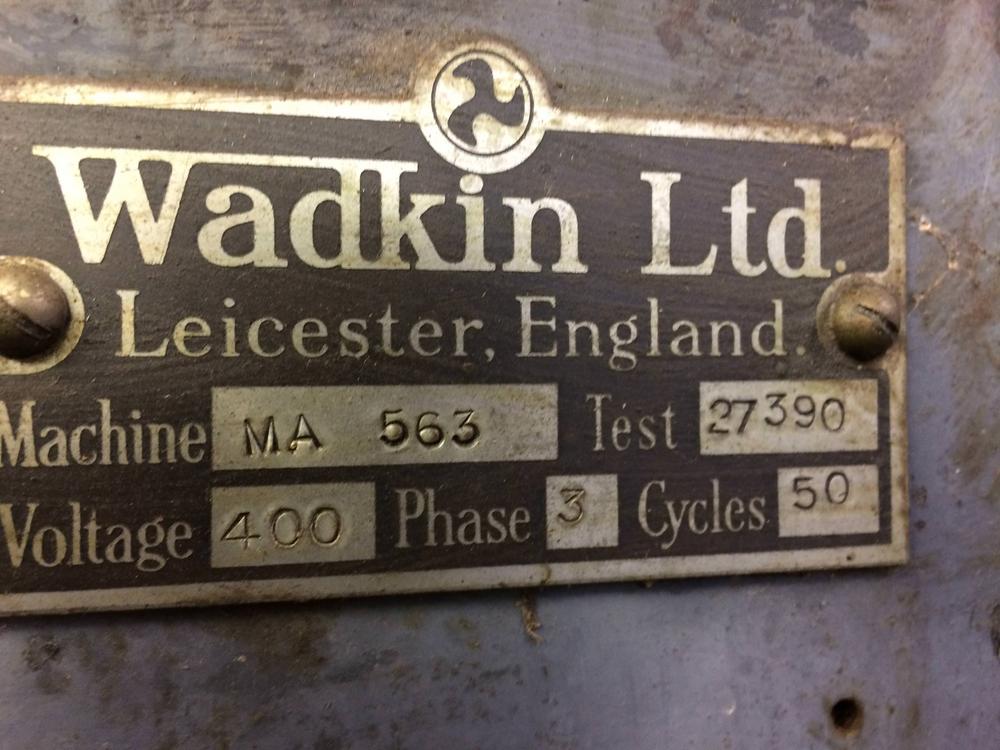

This one dates from 1946 which I think is wadkins wonder years

I really like using waxoyle to preserve metal, it works its way into everything and helps loosen stuff

I just love the way bolts that are 72 years old come out looking like this

My first balls up

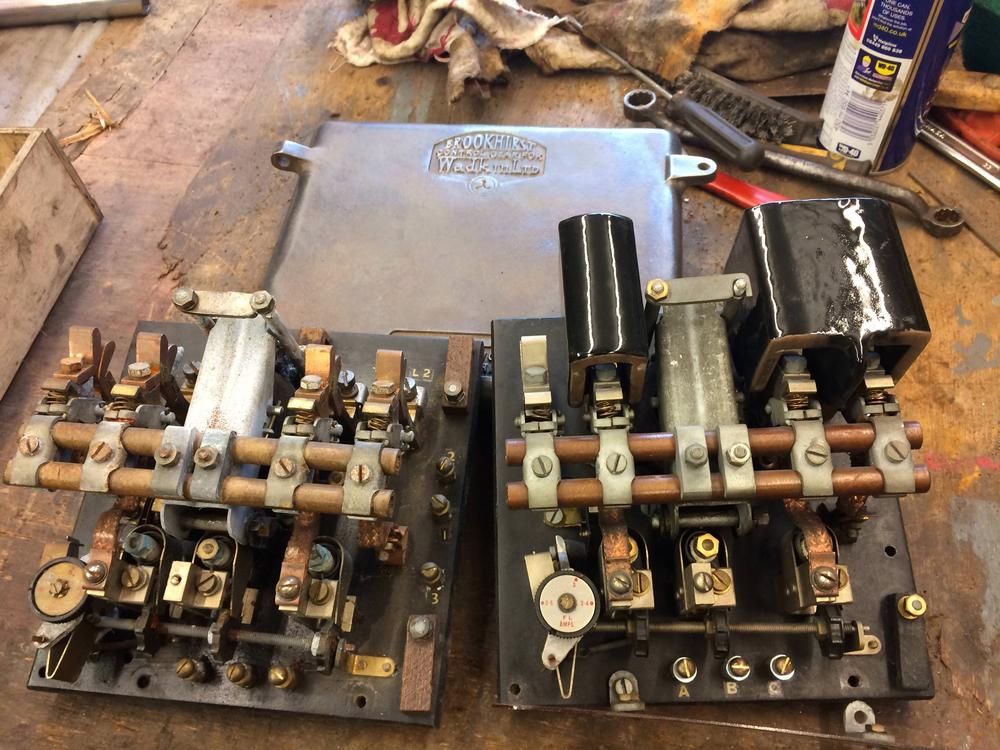

They made proper insulating tape back in the day, the brass screws in is connector look new

That motor and chain head are pretty heavy

I bought this about 3 years ago thinking it might have some good parts to salvage, but instead I'm going to try and resurrect it. Before I got it it had spent some time outside and since in my possession its sat out side smothered in waxoyle and covered with a tarp.

This one dates from 1946 which I think is wadkins wonder years

I really like using waxoyle to preserve metal, it works its way into everything and helps loosen stuff

I just love the way bolts that are 72 years old come out looking like this

My first balls up

They made proper insulating tape back in the day, the brass screws in is connector look new

That motor and chain head are pretty heavy