OldWood":1gxarlwl said:

Paul

Your input is from someone who is in the professional world. I think you are incorrect in raising all sorts of ghosts for the amateur and DIY environment - I consider that you are scare mongering, perhaps not deliberately, but because you take your job seriously and think that what applies there, applies to us all. It is not fair for you to quote PUWER98 at us - these are regulations for the work place and do not apply elsewhere, OK it might be that they represent good practice, but it certainly isn't the case for instance that insurance companies could penalise a homeowner for not complying. We are under no obligation whatsoever to ensure for instance that our bandsaws run down in 10 seconds, that our circular saws have all the protection covers; these may be desirable, but beyond that nothing. We have no one to sue if we damage ourselves and that is the key point. 20, 30, 50 years ago the loss of a finger was regarded as a hazard of the job and you lived with it; now in the litigious age, every company has to make sure they cover their a****s, and that is where you come in. Please stop the lecturing - it's not helpful.

Apart from the standard wiring regulations, there are no safety regulations that apply to the homeowner - Chas has pointed out for instance the significance of the DOL/NVR, but I am no obligations in terms of the law, or in fact the insurance company, to comply.

Rob

Rob,

My opening line I hoped, covers my comments, in that IF the machine is in use in a business undertaking then the business "rules" apply.

If this was not the case then sorry.

However, have you read your home insurance policy small print recently!

These companies have been hit hard by the global financial crisis and are looking for get out clauses not to pay claims to reduce their outgoings.

You may find that there are clauses in there which they will use “on” you if you had an issue relating to a fire originating in a machine you had wired/built/modified.

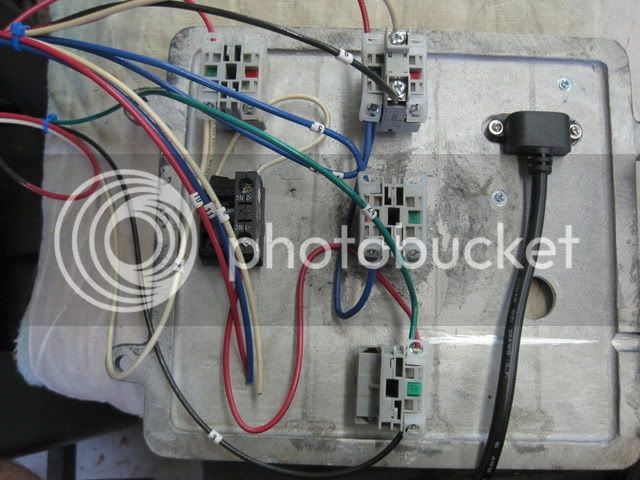

Apart from that, I am trying to make the point that for example a bleeder resistor could have a temperature rise of perhaps in excess of 100 deg Celsius in less than one second, now that could be an issue if you were touching it, or it were covered in wood flour could it not?

I am NOT scaremongering, I hoped to make that clear with my closing comment.

What I was trying to do was to put some facts down with regard to the engineering science, from an inverter manufacturers point of view, my last employer prior to my own business was with such a company on design/applications/service.

I feel that much of my post does have relevance to the DIY use of these devices.

It seems to me that there is a mixed bag of posters on here, some are DIY some seem to be running business ventures, unfortunately, all H&S legislation applies to businesses even sole traders it is just the complexity that varies with the size of the business. Am I incorrect? Is this a completely and wholly DIY forum, as it does not seem to be from some of the web sites I have looked up?

I hoped also to show obviously not well the rules that apply to businesses, i.e nvr, e-stops PUWER98 etc.

IMHO you would hope that one would fit some kind of emergency stop device when modifying a machine even for ones own use as in the event of an unforeseen incident you may be on your own at home (?) and the big red button may be the one that saves you!

I do make customers laugh, sometimes, as I have 2 sayings I use on them about safety “devices”!

The e-stop is the only button on the machine that matters, the green one only makes it go, and that is not really important as the big red one is the one that makes it stop when you need it to, now that is important!

The only wire that is important is the earth wire as that is the one that stops you from getting electrocuted, the others only make the machine work and in comparison they are pretty unimportant really, are they not?

If you want I’ll just leave the forum, no problem.

I contacted the mod team on joining and made them aware of my status and I was told that I would be monitored. This I expected & I believed was wholly right.

I have never hidden my status in the industry, which is the major reason for putting the information I have in my signature, thus it is obvious to all readers of my posts my background.

I have not yet made any approaches or attempted to ply my wares to any poster, I have attempted to move machinery for posters on to my trade contacts however, I have made it clear to them my intentions I did this in an effort to help them.