PhilipL

Established Member

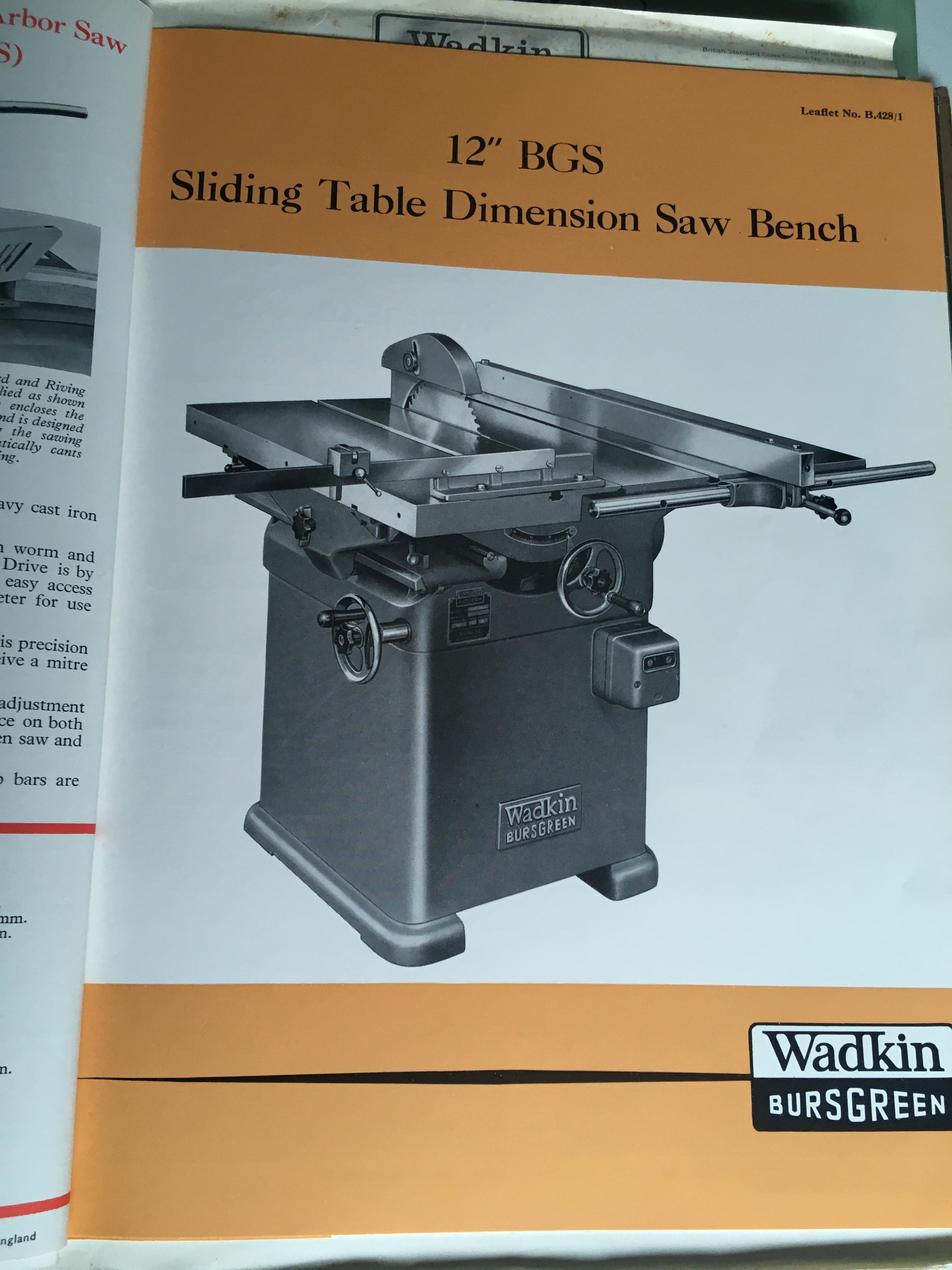

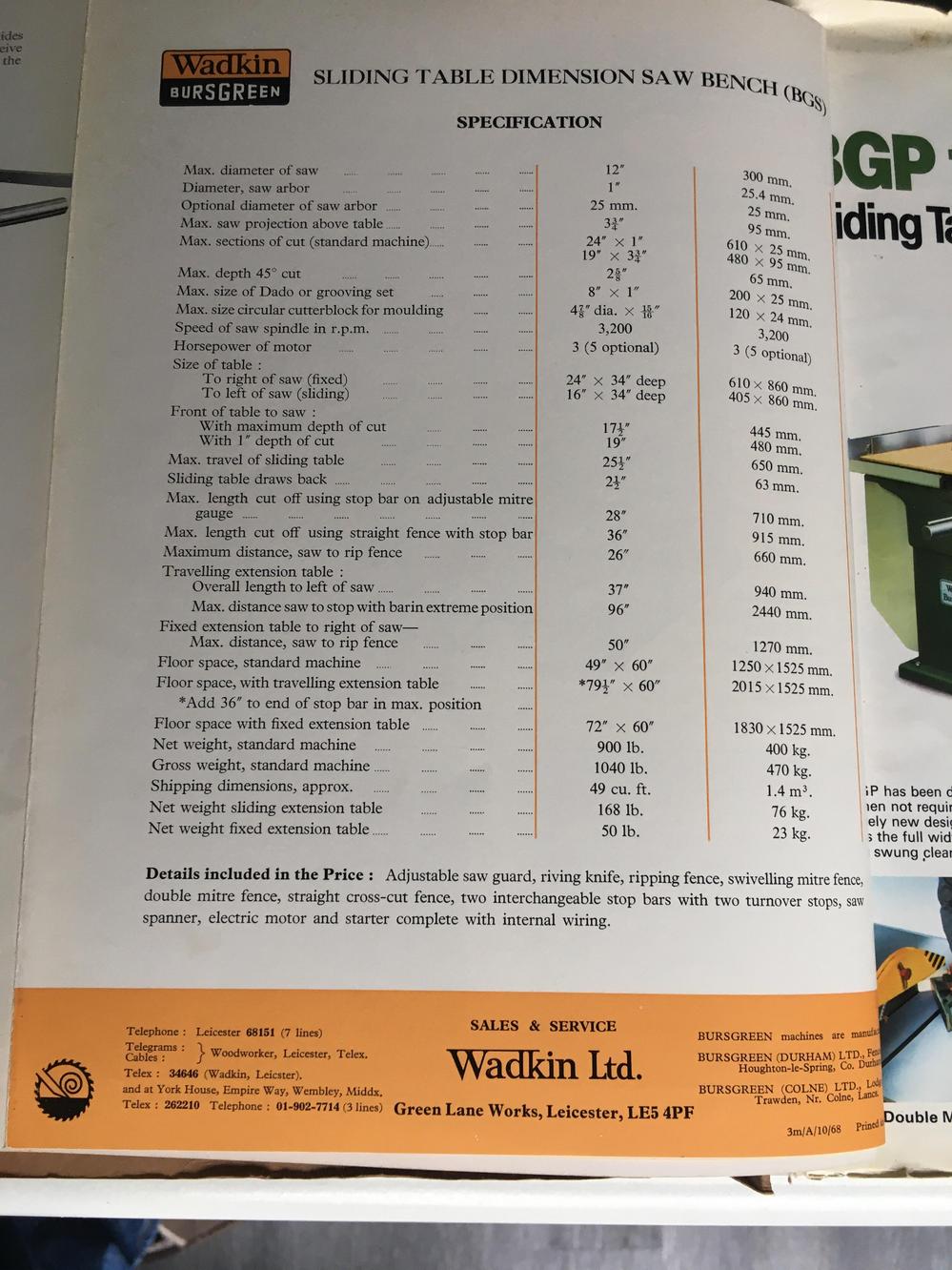

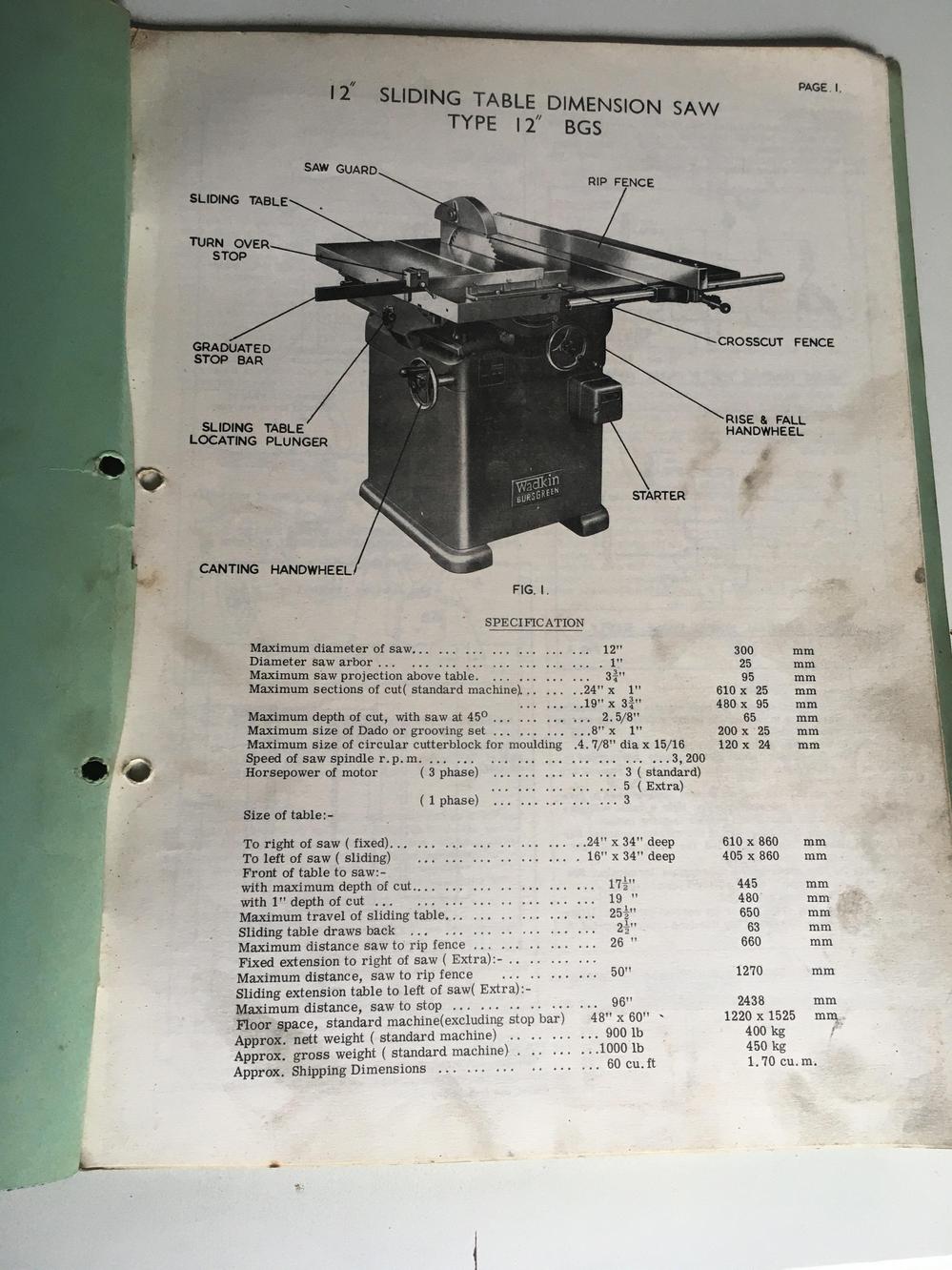

The BGS12 is more common to find, but is still rare compared the the AGS10. They usual command a significant price premium compared to the AGS10 or AGS12.

Until I sold all my workshop equipment a few months ago in a move to a flat I had a BGS12. Very substantial machine. I didn't really get so much interest in it when it was advertised, but it did eventually go to someone over in the west of NI.