MikeG.

Established Member

Don't get me wrong........the number 6 itself was absolutely bog standard, nothing special about it at all. What was unusual was the extent to which I had to go to restore it to working order. But let's start at the beginning.

Due to being away for a few days and leaving multiple bids in on Ebay in my absence, I found myself in possession of one more number 6 than I'd wanted to buy (for my son in law). I gave him the good one, having cleaned it up and sharpened it. No great story there. That left me with this beauty:

A bit of a clean up, flatten the bottom, and she'll be fine in an hour, I thought....... Well, an hour later:

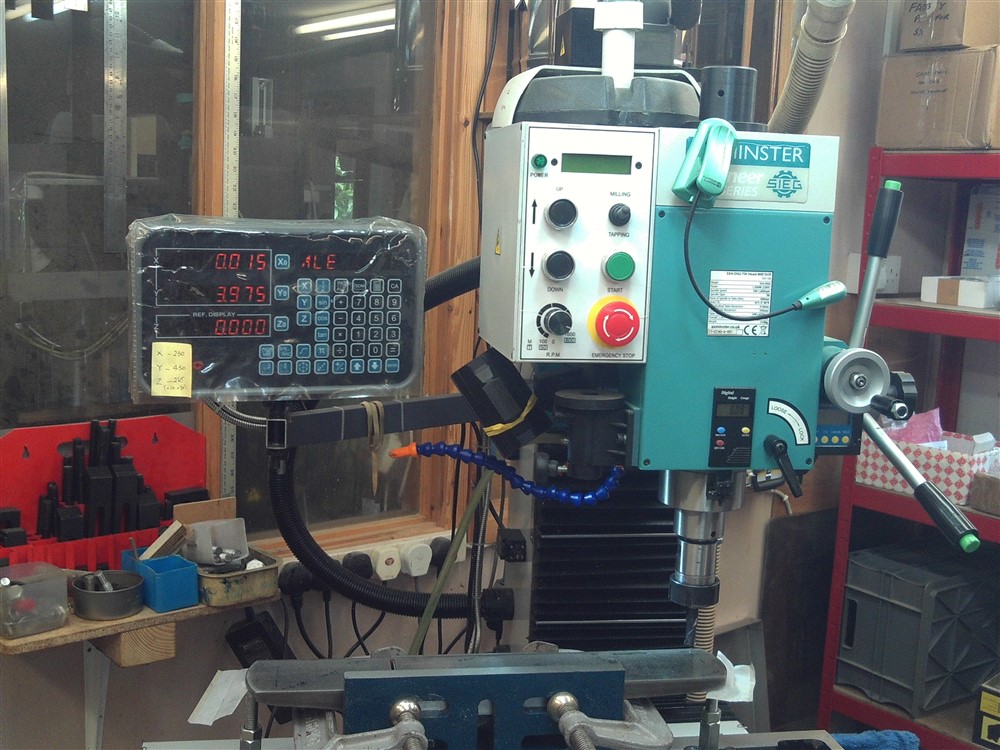

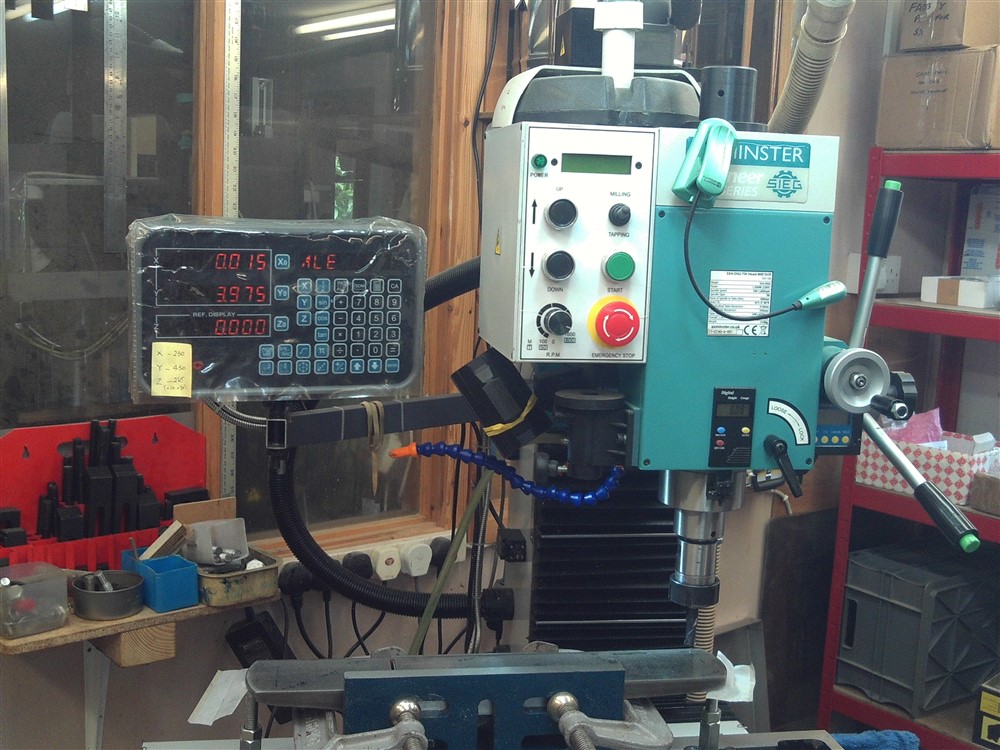

That was literally an hour of rubbing the thing on 60 grit, 80 grit......whatever I could find to scrape off the high points. I was miles from getting it flat. It was not only badly bowed end-to-end, but also twisted. God knows how it had got in such a state. Luckily, believe it or not, I have friends, and one of my friends has this bit of kit:

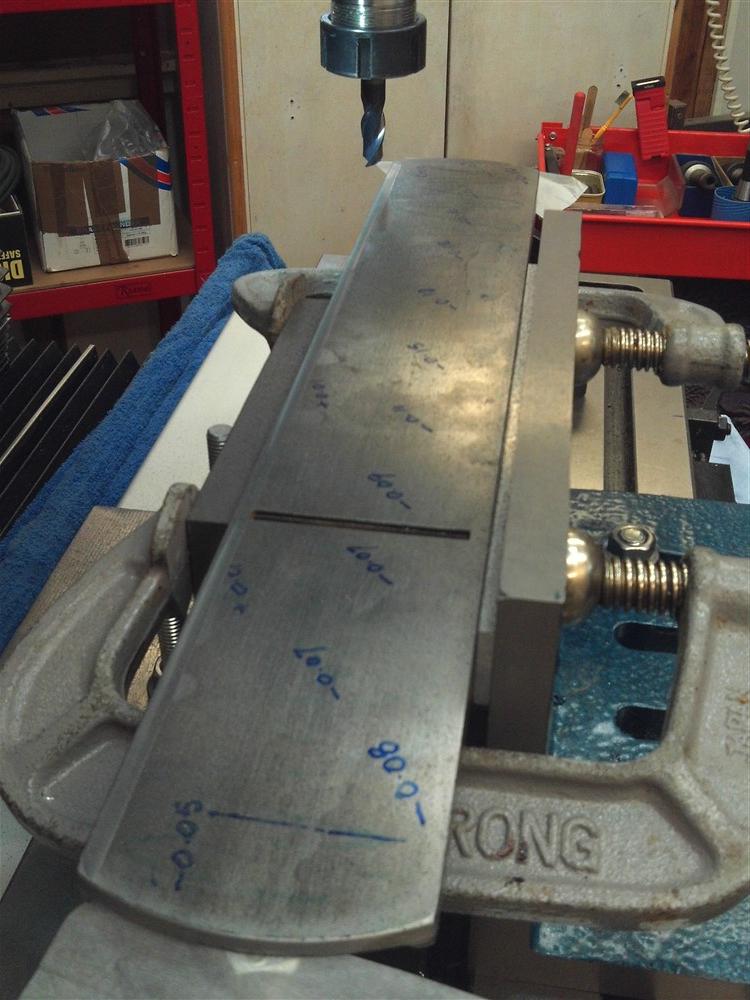

A computer controlled milling machine, fitted for this job with a brand new cobalt cutter. He spent a couple of hours making brackets which could hold the plane rock steady, then truing everything up, measuring the material to be removed, and so on. All very engineery, but gratifying to know that we were going to be removing the very least amount of cast iron possible:

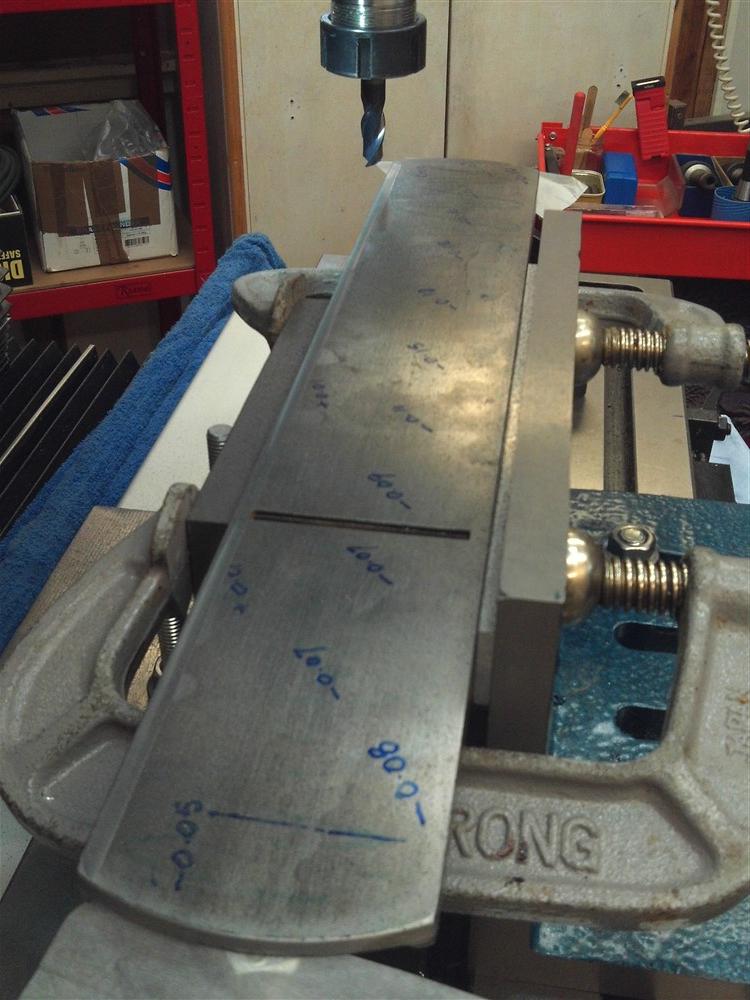

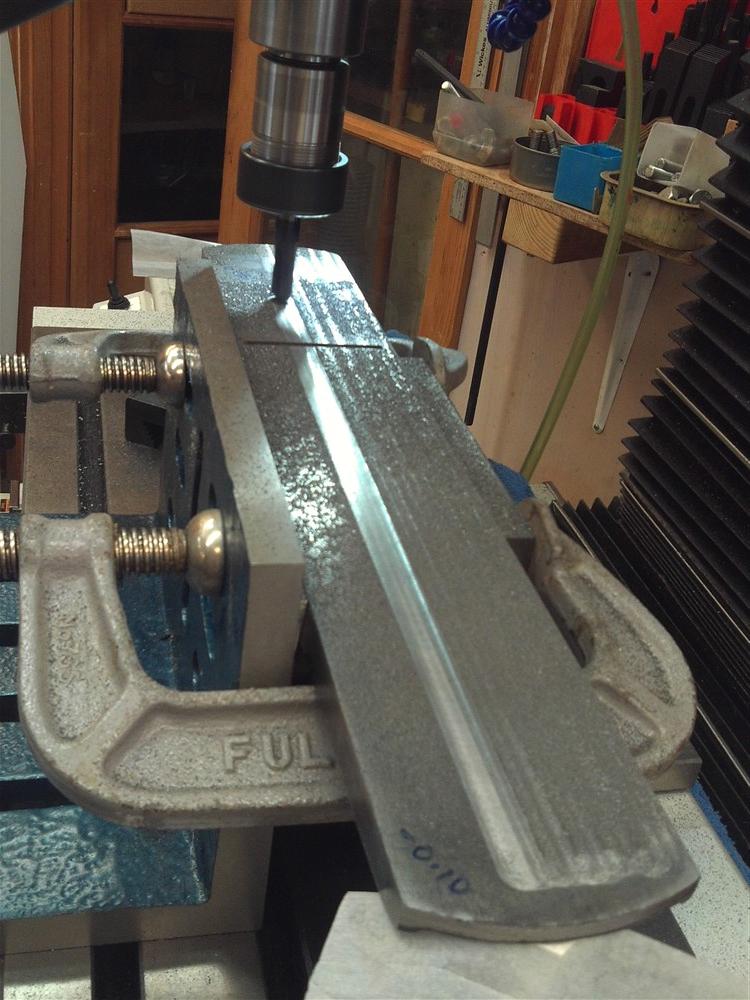

He also measured the amount of casting we had to play with, and it was very thick. With the blade in (but retracted, of course), and everything tensioned up, he ran the first cut:

To add to the complications, the length of travel on the machine was just a little short of the length of the sole of the plane, so I was going to be left with a a step at the heel end which I'd have to deal with myself manually.

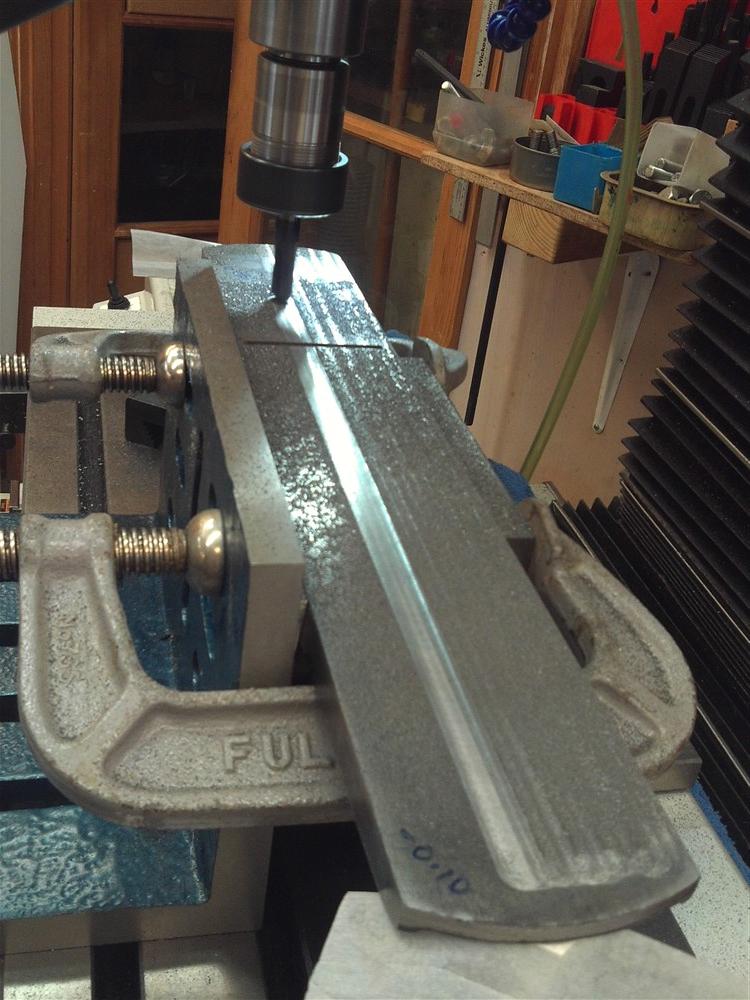

It took quite some time, maybe 45 minutes, but eventually it looked like this:

I know! It looks dreadful. The thing is, that was absolutely flat, with no discernible edges between those stripes. I couldn't feel anything, and pushing the bristles of a fine brush across it produced no flutter. This was just what the cutter left as "grain" in the casting. I took it home, and just a couple of minutes on the sandpaper-on-granite and I had a normal-looking flat bottom to my plane:

I cleaned this stuff up in the usual way:

And in no time it was working beautifully, albeit with a monster camber on the blade which I'll ease a little over time:

Due to being away for a few days and leaving multiple bids in on Ebay in my absence, I found myself in possession of one more number 6 than I'd wanted to buy (for my son in law). I gave him the good one, having cleaned it up and sharpened it. No great story there. That left me with this beauty:

A bit of a clean up, flatten the bottom, and she'll be fine in an hour, I thought....... Well, an hour later:

That was literally an hour of rubbing the thing on 60 grit, 80 grit......whatever I could find to scrape off the high points. I was miles from getting it flat. It was not only badly bowed end-to-end, but also twisted. God knows how it had got in such a state. Luckily, believe it or not, I have friends, and one of my friends has this bit of kit:

A computer controlled milling machine, fitted for this job with a brand new cobalt cutter. He spent a couple of hours making brackets which could hold the plane rock steady, then truing everything up, measuring the material to be removed, and so on. All very engineery, but gratifying to know that we were going to be removing the very least amount of cast iron possible:

He also measured the amount of casting we had to play with, and it was very thick. With the blade in (but retracted, of course), and everything tensioned up, he ran the first cut:

To add to the complications, the length of travel on the machine was just a little short of the length of the sole of the plane, so I was going to be left with a a step at the heel end which I'd have to deal with myself manually.

It took quite some time, maybe 45 minutes, but eventually it looked like this:

I know! It looks dreadful. The thing is, that was absolutely flat, with no discernible edges between those stripes. I couldn't feel anything, and pushing the bristles of a fine brush across it produced no flutter. This was just what the cutter left as "grain" in the casting. I took it home, and just a couple of minutes on the sandpaper-on-granite and I had a normal-looking flat bottom to my plane:

I cleaned this stuff up in the usual way:

And in no time it was working beautifully, albeit with a monster camber on the blade which I'll ease a little over time: