Documenting a day of underachievement. Well, half a day. I do have to earn a living now and then.

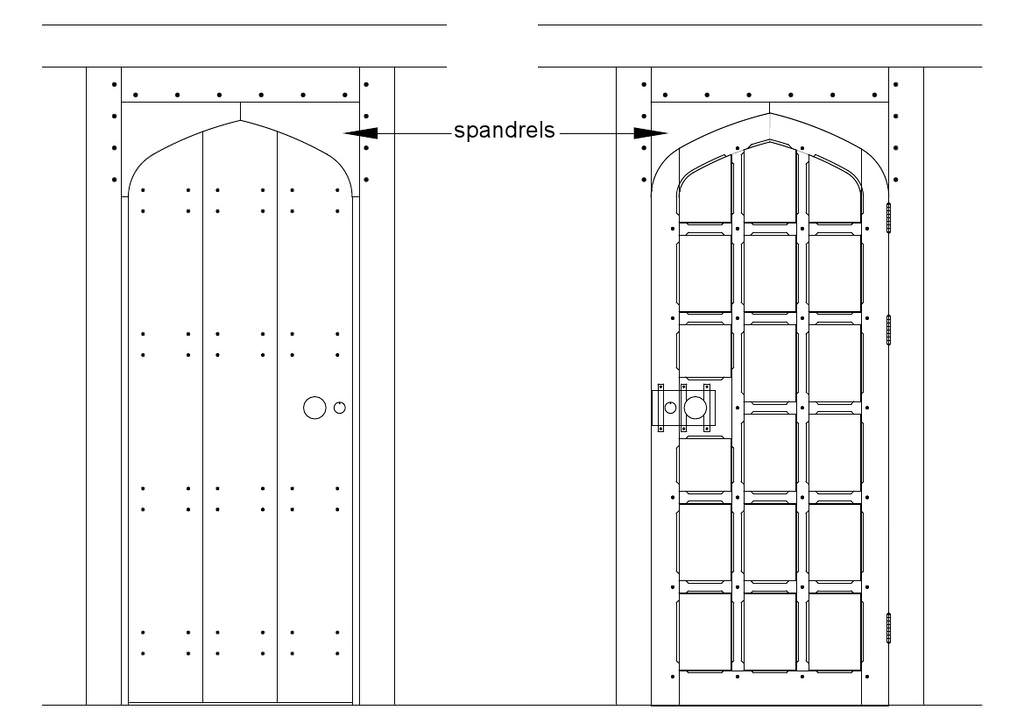

This door incorporates a sheet of 6mm oak faced ply, and when I bought it, it came sandwiched between a sheet of cardboard and a sheet of 3mm MDF. That was a bonus, because I wanted the MDF. This door is nearly 3 inches thick, and will weigh an absolute ton. I don't want to be standing it in place, adjusting, trying again, adjusting, and so on. I want it right first time, so, I made a template. Marking it up:

I thought I should start with the centre of the three layers to this door. This needs to be 31mm thick, to accommodate the insulation (25mm) and the ply (6mm). I had an old plank of oak which was 36mm thick.....perfect!

Let me walk you through preparing the stock. Jump ahead if this is old hat. Here is what I started with:

I used the winding sticks to determine that although there was a good couple of metres of the board which was pretty straight, it was twisted, and twisted enough that I wouldn't be able to plane it up as a whole, but I'd have to do it in individual pieces (I wanted bits approx 70mm wide). So, I sliced it up first:

This gave me three pieces about 2200 long, all with a twist. Out with the plane, and the winding sticks:

This is merely to flatten one face enough to pass the board through the thicknesser part of the P/T. Neither face will be seen in the finished door.......this is a very unusual door, I say again...........so it wasn't imperative to get each face perfect. As it turned out, there was just enough thickness to allow the entirety of both faces to be properly planed. The shorter pieces were cut 3 or 4 inches over-length and planed up as per the longer ones, only it is a much simpler process with short bits of wood. The shorter you can cut the wood, the less planing you have to do to get the twist out. Here are all the bits dropped roughly in place over the template:

As I am sure you know by now, I love proper joints. These are a pair of mortise and tenons (with a small haunch) at the bottom corners of the door. This frame is NOT holding the door square, so there is no need for a through tenon, or wedges:

A 12mm mortise, chopped out with a bevel edge bench chisel (because that's all I have, or need):

With a quick haunch, for resistance to twisting):

Tenon marked out:

Shoulders cut with a knife just to provide a guide for the tenon saw (I didn't need to go to this trouble because, as I said, the faces of this frame will never be seen........but I've looked forward to making this door for a long time, and I was rather savouring it):

You can see I sawed the faces of the tenons, then pared to the line with a 1-1/2" chisel.

It slipped together first time. That's what you get when your stock is properly prepared:

So that's the bottom rail dealt with, dry fitted and offered up to the template to aid marking out the top pieces:

This is the middle joint of the upper two pieces. It will be a long bridle joint, and it needs to be neat because it will be at eye level prominently in the edge of the door. Bridle joints, often taught as one of the first joins you learn, are actually a damned difficult joint to get spot on. Anyway, the shoulders as before, knife then tenon saw:

I roughed off the waste with a handsaw, then cleaned up with the big chisel as always:

Same principle but t'other way around with the female part of the joint. I drilled a hole near the inner shoulder/ face of the joint, sawed down to it, then cleaned up with the chisel (you know how sometimes you get the sharpening absolutely bang-on, and the tool is like a razor......well, that happened, and it makes this job a joy):

I glued it all up, and that's it for the day. Like I said.......something of an underachiement: