Derek Cohen (Perth Oz)

Established Member

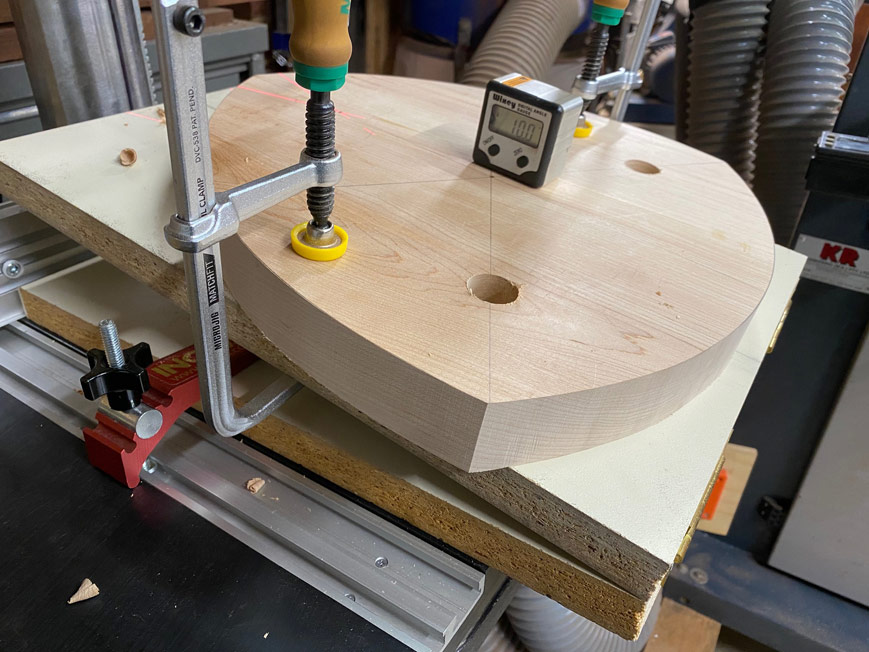

For the past 25 years, we have lived with these Ikea bench stools in our kitchen ...

We do not eat much at the bench, but they get used. More recently Lynndy suggested that we replace them, and I thought that this would be a good excuse to build something inspired by Wharton Escherick, whose stools are just so organic and profound in their simplicity.

The design was also influenced by a point made by Lynndy that a fixed-height footrest does not fit everyone. I thought about this and it occurred to me that the stretchers on the Escherick stools could form the basis of a slightly different design - make the seat three-sided, and one could choose the stretcher height to suit.

The last requirement was that the wood must be Hard Maple, to match the kitchen I built a few years ago. I would have preferred a contrasting top, say in Walnut, but She Who Must Be Obeyed vetoed this. So ...

I did manage to get contrasting wedges for the tenons passed her

The stretchers ....

One last one ...

I'll am happy to post build photos if there is interest.

Regards from Perth

Derek

We do not eat much at the bench, but they get used. More recently Lynndy suggested that we replace them, and I thought that this would be a good excuse to build something inspired by Wharton Escherick, whose stools are just so organic and profound in their simplicity.

The design was also influenced by a point made by Lynndy that a fixed-height footrest does not fit everyone. I thought about this and it occurred to me that the stretchers on the Escherick stools could form the basis of a slightly different design - make the seat three-sided, and one could choose the stretcher height to suit.

The last requirement was that the wood must be Hard Maple, to match the kitchen I built a few years ago. I would have preferred a contrasting top, say in Walnut, but She Who Must Be Obeyed vetoed this. So ...

I did manage to get contrasting wedges for the tenons passed her

The stretchers ....

One last one ...

I'll am happy to post build photos if there is interest.

Regards from Perth

Derek