Hello,

I have finally decided to buy Laguna 1412 bandsaw in the near future (was considering Sabre 350, but I have read about people having issues with poor dust collection).

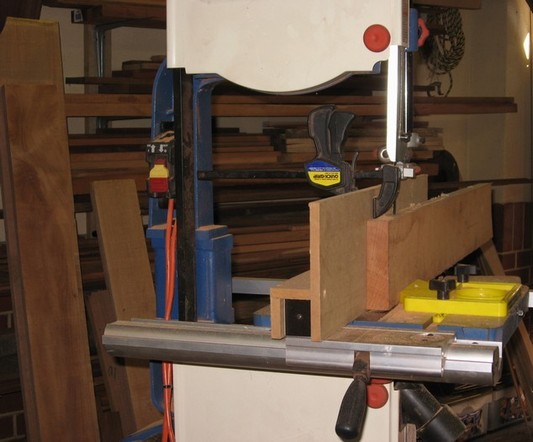

I will still dimension the wood with hand planes. Is there anybody, who is (or was) thicknessing wood on the bandsaw? I.e. planing the reference face and edge with hand planes and then standing the board on the edge and running the board through the band saw 1-2 mm away from the line and then finishing with the hand planes? Will the result be coplanar as from the thicknesser or it will be far from it?

Is this method reliable with a quality bandsaw? I think that @Derek Cohen (Perth Oz) mentioned somewhere, that he used it prior to buying a jointer/thicknesser, but I am not sure if I remember correctly.

I have decided for Hammer A3-26 jointer/thicknesser as the next machine, but it might take a lot of time to save up for it, so I would like to use the bandsaw approach for thicknessing.

Thank you.

I have finally decided to buy Laguna 1412 bandsaw in the near future (was considering Sabre 350, but I have read about people having issues with poor dust collection).

I will still dimension the wood with hand planes. Is there anybody, who is (or was) thicknessing wood on the bandsaw? I.e. planing the reference face and edge with hand planes and then standing the board on the edge and running the board through the band saw 1-2 mm away from the line and then finishing with the hand planes? Will the result be coplanar as from the thicknesser or it will be far from it?

Is this method reliable with a quality bandsaw? I think that @Derek Cohen (Perth Oz) mentioned somewhere, that he used it prior to buying a jointer/thicknesser, but I am not sure if I remember correctly.

I have decided for Hammer A3-26 jointer/thicknesser as the next machine, but it might take a lot of time to save up for it, so I would like to use the bandsaw approach for thicknessing.

Thank you.