woodbloke

Established Member

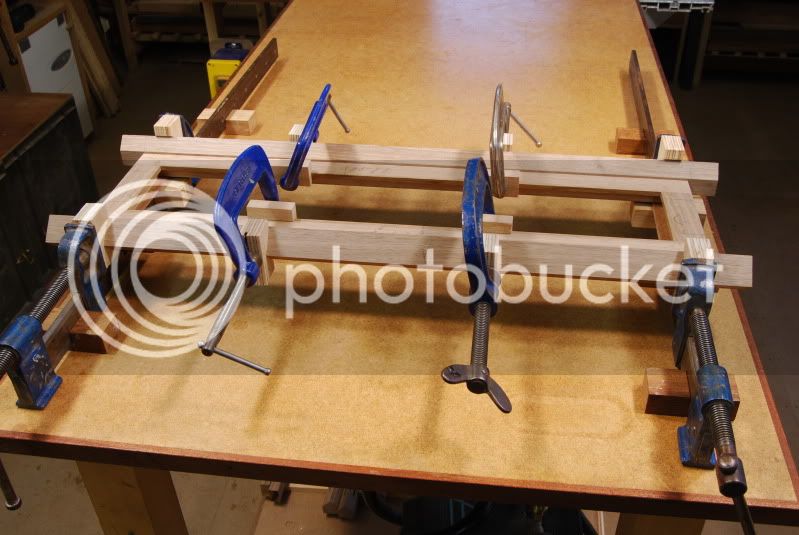

Following one from Dougless's walnut box on the General Woodwork forum, I've just been waiting for the wood to finish it's second conditioning in the 'shop before I start construction, having been machined oversize a couple of months ago. Once it's ready, it'll be skimmed through the p/t to final dimensions and then hand planed. The timber is English Walnut from one of several boards I got just before Christmas last year, but as is usual when I don't know what I'm doing :roll: (which happens fairly frequently) I've made a mock up of one side:

...showing the corner styles that are set in at 45deg to both the back panel and side panels. The side panels and door will of course be glazed but the back panel:

...was part of a set of doors that I made for a very large cabinet in the late 70's, so it ought to be well seasoned by now. Shown in the pic being shot in to size having been hand planed down to 9mm. Once the other timber is fit to use, the back panel will be be made first and then everything else made to fit round it. Top and bottom will be 2mm Walnut veneers over lipped ply. Comments thus far, good, bad or indifferent welcome - Rob

...showing the corner styles that are set in at 45deg to both the back panel and side panels. The side panels and door will of course be glazed but the back panel:

...was part of a set of doors that I made for a very large cabinet in the late 70's, so it ought to be well seasoned by now. Shown in the pic being shot in to size having been hand planed down to 9mm. Once the other timber is fit to use, the back panel will be be made first and then everything else made to fit round it. Top and bottom will be 2mm Walnut veneers over lipped ply. Comments thus far, good, bad or indifferent welcome - Rob