You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tablesaw Crosscut Sled problems

- Thread starter wizer

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

9fingers

Established Member

jasonB":1897kvmr said:9 fingers and Digit I think Toms problem is that the fence (front part) is not 90 deg to the blade eg the work is being held at 88deg not 90. So the relation of the fence to the slots is the issue as this WILL affect the cut

Jason

Jason, That does not actually matter.

The only critical part is the parallelism between the axis of motion and the cutting tips of the saw.

I know it feels wrong but give it a try.

Bob

If you want proof, set the slot parallel and your mitre gauge a couple of degrees off 90. Push a test piece through the saw holding the stock firmly in the mitre gauge and you will find that it has cut 90 despite the setting on the gauge.

So when I want a 45deg mitre I set my gauge to 45 and it cuts 45 Not 90

If what you are saying is true why have mitre gauges if at all settings they will cut the wood at 90degrees. :?

Just like a sliding carrage the FENCE must be at 90degrees to the blade/direction of travel to cut at 90deg, 1 degree either way will give me 89 or 91

Jason

This always causes difficulties for people Jason but I'm afraid it's true.

Look at this way. You set to 45, the mitre gauge running in the slot, the blade is 90 degrees to that slot, now run the last few mill of the wood past the blade so that the teeth will cut it, what angle will that cut be?

Roy.

Look at this way. You set to 45, the mitre gauge running in the slot, the blade is 90 degrees to that slot, now run the last few mill of the wood past the blade so that the teeth will cut it, what angle will that cut be?

Roy.

There must be some cross purpose talking here. But I don't know where.

As Jason says, if the fence isn't 90degrees to the blade, then you won't get a 90degree cut, irrespective of anything else. If you set the fence to 45degrees, you'll get a 45 degree cut.

Unless i'm missing something. :?

Cheers

Karl

As Jason says, if the fence isn't 90degrees to the blade, then you won't get a 90degree cut, irrespective of anything else. If you set the fence to 45degrees, you'll get a 45 degree cut.

Unless i'm missing something. :?

Cheers

Karl

Steve Maskery

Established Member

I don't get this guys. I'm sat here reading stuff from people I normally respect (  ) telling me something that appears to me to be nonsense! I'm with Jason on this. If the fence is not square to the slot, I agree the cut will still be square VERTICALLY, but not horizontally. That's why we have mitre fences, for when we want the cut NOT to be square! Isn't it?

) telling me something that appears to me to be nonsense! I'm with Jason on this. If the fence is not square to the slot, I agree the cut will still be square VERTICALLY, but not horizontally. That's why we have mitre fences, for when we want the cut NOT to be square! Isn't it?

The fence must be square to the slot, which, IIUIC, Tom's problem. It's less important (at least, in this respect) that the slot (and hence the fence) be parallel to the blade (although if it is VERY far out you could get pressure problems ont he body of the blade, depending on which way out it is).

Puzzled Steve

The fence must be square to the slot, which, IIUIC, Tom's problem. It's less important (at least, in this respect) that the slot (and hence the fence) be parallel to the blade (although if it is VERY far out you could get pressure problems ont he body of the blade, depending on which way out it is).

Puzzled Steve

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£49.91

£58.33

Mefape Mortise and Tenon Jig Tools for Woodworking Routers, Tenon Cutter, Manual Mortising Machine, Invisible Slotting Machine Jig Stand, 3-Axis Guide Rail for Adjust Trimming Length and Width

wangshijuntianjinhongyuegongyipin

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

When you say Fence Karl are we talking the edge of the sled that the piece you wish to cut is resting against?

If so the angle of the blade has no effect on the sawn end of the timber that you cut.

If that stop that the timber is resting against is at 90 to the slot the sawn end will be 90 regardless of the angle the blade is to that slot.

Roy.

If so the angle of the blade has no effect on the sawn end of the timber that you cut.

If that stop that the timber is resting against is at 90 to the slot the sawn end will be 90 regardless of the angle the blade is to that slot.

Roy.

Steve Maskery

Established Member

So we are not at odds???????? Well I'm glad, but I think I'm going to have to go and lie down.

S

S

Steve Maskery

Established Member

Steady on...!

wizer

Established Member

- Joined

- 3 Mar 2005

- Messages

- 15,589

- Reaction score

- 1

Steve Maskery":2qe1h7y4 said:I think I'm going to have to go and lie down.

I am laying down and I'm not sure I completely get it !!

Ultimately, I think the message is that I need to get the saw setup correctly. I've not checked it since I got it and, since 2010 is going to mainly setting up my workshop, I should sort it out (or at least check it). I'm not getting square cuts from the fence so that needs looking at anyway. Fitting an after market fence seems like a viable port of call. I can't get on with the short fence anyway.

Once Setup, I will follow the advice here to get the fence of the sled 90 degrees to the blade. Hopefully then I would have covered both opinions here.

Thanks all. I thought this was going to be a simple one.

That's a nice way of putting it Roy. There's several of us using slightly different language to describe the same phenomenon.

To pitch it from another angle Wiz. I've seen a 1960s US article on a using a RAS which suggests using a saw blade set vertically in the plane of the blade disc, but at 45 deg to the direction of feed along the fence (when viewed from vertically above the plane of the table), and cutting mostly off the side of the teeth to mould a large coving/concave moulding of similar diameter to the sawblade!

I've also seen an article by a respectable contributor to one of the posh mags on how to make a sled clearly not understand that a saw can cut off the side of its teeth like this.

To try and explain the issue. When you cut on a table saw the blade has only a very moderate guiding effect. This because as above the teeth are happy within reason to cut in pretty much any direction. e.g. you can feed (carefully) a workpiece into the blade at quite a sharp angle (e.g. 45 deg on a cross cut fence - but not recommended unless you are feeling brave) to the plane of the disc and it will still cut. The resulting kerf will be a bit weird - basically part of the ellipse the blade appears to form when viewed along the line in which the workpiece is being fed.

Another way of experiencing this. I've been know to (very naughtily - i wouldn't do it now) feed a piece freehand into the blade without using a fence to rip/nibble out a short slot in the end of a piece - working to a marked out line. You would find if you were foolish enough to do this that you have to control the position of the piece sideways as well as the blade is quite as happy to cut sideways as it is in the direction of the slot.

To get back to the mitre slots. They determine the line in which the piece is fed to the blade. So when the piece contacts the blade it will still as above cut regardless of whether or not it's aligned parallel to the slots.

If the blade is out of parallel to the slots, then the problem is that you will get an elliptical section kerf, also as above. This kerf will however (because the blade has no real preference in terms of which direction it cuts) still be straight and parallel to the slots/direction of feed.

The blade does not need to be set up parallel to the line of the slots to get a straight cut. It does if you want to simultaneously get a vertical sided parallel kerf, and to avoid the trailing side of the blade roughing up one cut face. (that zinging noise)

My guess is that the misunderstanding gets overlooked if you are pernickety about setting the blade parallel to the mitre slots or the direction of movement of your sliding table - because if in that case you reference off the plane of the blade disc to square a 90 deg cross cut it will cut square. i.e. it cuts square, but only because in that specific situation by aligning off the blade you end up square to the slots. Right result, wrong reason.

If on the other hand the alignment of your blade is a bit sloppy relative to the slots/direction sliding table travel (as was the case initially with my Robland, i wasn't experienced enough to check it out) you'll be left wondering how it is that the damn thing is not cutting square or cleanly despite your fence being aligned accurately at 90 deg to the blade.

The reason is of course the above.....

This probably just muddies the water even further, it really needs a drawing to be clear. You're probably right about needing to check the alignment of the saw.

ian

To pitch it from another angle Wiz. I've seen a 1960s US article on a using a RAS which suggests using a saw blade set vertically in the plane of the blade disc, but at 45 deg to the direction of feed along the fence (when viewed from vertically above the plane of the table), and cutting mostly off the side of the teeth to mould a large coving/concave moulding of similar diameter to the sawblade!

I've also seen an article by a respectable contributor to one of the posh mags on how to make a sled clearly not understand that a saw can cut off the side of its teeth like this.

To try and explain the issue. When you cut on a table saw the blade has only a very moderate guiding effect. This because as above the teeth are happy within reason to cut in pretty much any direction. e.g. you can feed (carefully) a workpiece into the blade at quite a sharp angle (e.g. 45 deg on a cross cut fence - but not recommended unless you are feeling brave) to the plane of the disc and it will still cut. The resulting kerf will be a bit weird - basically part of the ellipse the blade appears to form when viewed along the line in which the workpiece is being fed.

Another way of experiencing this. I've been know to (very naughtily - i wouldn't do it now) feed a piece freehand into the blade without using a fence to rip/nibble out a short slot in the end of a piece - working to a marked out line. You would find if you were foolish enough to do this that you have to control the position of the piece sideways as well as the blade is quite as happy to cut sideways as it is in the direction of the slot.

To get back to the mitre slots. They determine the line in which the piece is fed to the blade. So when the piece contacts the blade it will still as above cut regardless of whether or not it's aligned parallel to the slots.

If the blade is out of parallel to the slots, then the problem is that you will get an elliptical section kerf, also as above. This kerf will however (because the blade has no real preference in terms of which direction it cuts) still be straight and parallel to the slots/direction of feed.

The blade does not need to be set up parallel to the line of the slots to get a straight cut. It does if you want to simultaneously get a vertical sided parallel kerf, and to avoid the trailing side of the blade roughing up one cut face. (that zinging noise)

My guess is that the misunderstanding gets overlooked if you are pernickety about setting the blade parallel to the mitre slots or the direction of movement of your sliding table - because if in that case you reference off the plane of the blade disc to square a 90 deg cross cut it will cut square. i.e. it cuts square, but only because in that specific situation by aligning off the blade you end up square to the slots. Right result, wrong reason.

If on the other hand the alignment of your blade is a bit sloppy relative to the slots/direction sliding table travel (as was the case initially with my Robland, i wasn't experienced enough to check it out) you'll be left wondering how it is that the damn thing is not cutting square or cleanly despite your fence being aligned accurately at 90 deg to the blade.

The reason is of course the above.....

This probably just muddies the water even further, it really needs a drawing to be clear. You're probably right about needing to check the alignment of the saw.

ian

It's a bit like trying to understand that people in Australia are upside down relative to us. Some people simply can't see it Ian. I've had apprentices walking away shaking their heads in disbelief.

Roy.

Roy.

jimi43

Established Member

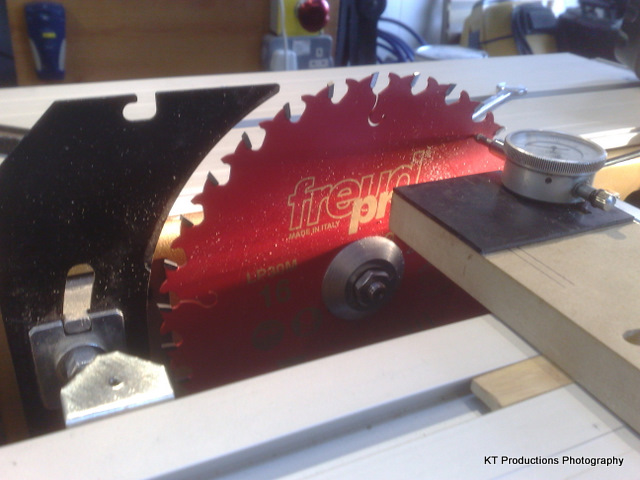

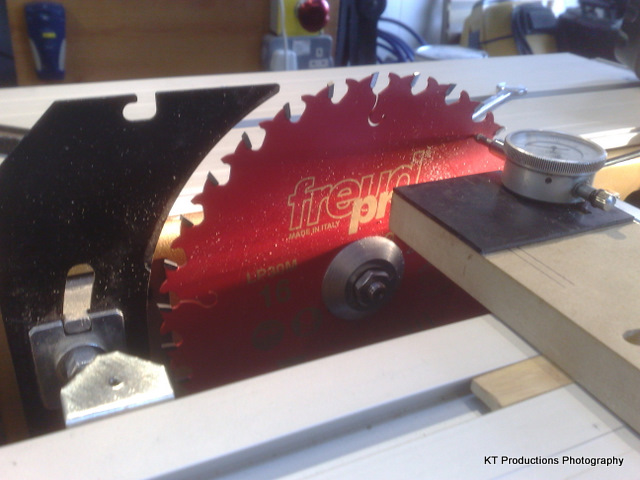

Setting up the blade parallel to the mitre slot...my solution:

Probably a bit of an overkill but fun and I had a spare dial gauge..they are cheap as chips on fleaBay.

Cheers

Jim

Probably a bit of an overkill but fun and I had a spare dial gauge..they are cheap as chips on fleaBay.

Cheers

Jim

devonwoody

Established Member

complicated project is making a sled.

Wizer if you have the energy left try this.

estimate how far you are out of square and hand plane up a new false rear fence and keep planing until you get a true square, then clamp the new fence with glue to the old fence inside with screw holes already prepared.

When glue has set do a cut and if satisfactory put in the screws. Mind you if you used ply for a base this damp cold weather means that it will not be stable.

Are you on steroids yet? :wink:

PS don't use much glue otherwise it will push the accuracy of the set up again.

Wizer if you have the energy left try this.

estimate how far you are out of square and hand plane up a new false rear fence and keep planing until you get a true square, then clamp the new fence with glue to the old fence inside with screw holes already prepared.

When glue has set do a cut and if satisfactory put in the screws. Mind you if you used ply for a base this damp cold weather means that it will not be stable.

Are you on steroids yet? :wink:

PS don't use much glue otherwise it will push the accuracy of the set up again.

I agree to an extent that the blade does not have to be parallel to the slot*

Looking at Jimis picture above, the edge of his bit of MDF is what I hope we are talking about, if this were at an angle to teh slot then the wood when held against it would not be cut at 90deg.

I'll tak esome photos later today to clarify what I am talking about.

* If taken to extreams and the blade is a long way off then the cut will be concave as mentioned above as its like cutting a cove. Not what you want.

Jason

Looking at Jimis picture above, the edge of his bit of MDF is what I hope we are talking about, if this were at an angle to teh slot then the wood when held against it would not be cut at 90deg.

I'll tak esome photos later today to clarify what I am talking about.

* If taken to extreams and the blade is a long way off then the cut will be concave as mentioned above as its like cutting a cove. Not what you want.

Jason

Similar threads

- Replies

- 0

- Views

- 343

- Replies

- 20

- Views

- 1K