jimi43":3gdzz3ng said:

Aside from kickback the main cause of severed fingers is a slip which tends to come after stress relief. When stock gets stuck for some reason...knots etc...then pushing harder nearer the blade when it gives in smooth stock makes you fall forward.... :roll:

I ALWAYS stand to the side...use a push rod that reaches right over the pre-bed to the blade and don't reach forward....accident waiting to happen there!

Jim

Hi Jim

Standing on the side is ok but, which side...

Please have a look at this site and you'll see that there are 2 kinds of kickback....

http://www.waterfront-woods.com/Article ... blesaw.htm

1.Back-side kickback

2. Over-the-top kickback

As for the Back-side kickback, there are no problems...the workpiece is coming directly back to the operator and we know where to stand

It is the Over-the-top kickback that is confusing me...as you will see on the following video, the workpiece is lifted up - on top of the blade - turned (you can see the marks) Anti-clockwise and propelled to the left side of the blade and, if the operator is there....well...

http://www.metacafe.com/watch/910584/ta ... nstration/

http://www.metacafe.com/watch/910584/ta ... nstration/

I'm standing at any convenient place (that I can stand stabilized) but always using the Riving Knife, featherboard, the crown guard - I belive that the crown guard connecting bolt (to the guard) will reduce the intensity of the kickback by not letting the workpiece to climb on the blade top...

And of course, a short fence extending up to the blade centre (Arbor)...

I also use "High blade" but that's personal...

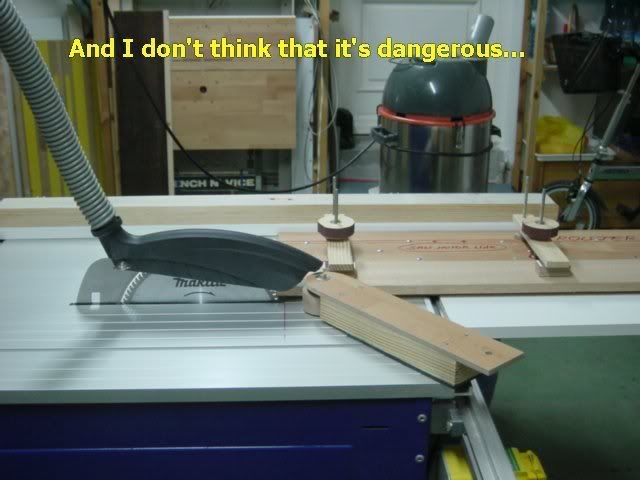

I set the fence almost to the Arbor center (the hole that you see on the table near the blade center is for pushing a pin to lock the Arbor for blade change).

As you noticed, I love "high blade" for ripping solid wood. It's easier on the motor, the feed rate is faster and the cut is cleaner without burn marks but of course, I use the blade guard that covers this "meat and bones slicer" totally.

Ready to cut...please note that I'm using the "Low fence" even though the board is only 30mm thick.

It gives me more "open area" and actually the "High fence" in not needed even if the board was 3" except in the case of re-sawing (that I never did on the TS)

I'm still using my hand to push the board from the end

But that's the point that I revert to push stick

Last push.....

Done...please note where is my hand when the cut is finished...

As you can see, no burn marks even though I use 60 tooth blade...

Sometimes, I'm using 80T or even 100T blade for ripping (the Makita on the pic)...

Regards

niki