Matt_S

Established Member

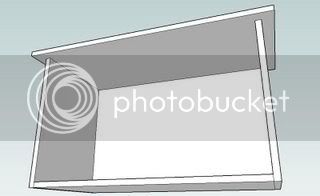

I'm making some drawer units, from ply. I've done woodworking in uni/school workshops but I'm having difficulties in working out best way to do stuff now I'm garage based! The main thing I think is realising the limitations of my hand tool skills as I would have just used big machines before.

I'm wondering with my limitations both skills and tools how to end up with nice square panels at the right size! When they're too large for my small table saw (most are) if I rough down to size with jigsaw (don't have circular saw) could I use a router against a straight edge to do a final cut?

I presume I could cut by hand nice and close then finish with plane, this sounds good but beyond me, always end up with opposite high and low corners when planing an edge

Any suggestions?

I'm wondering with my limitations both skills and tools how to end up with nice square panels at the right size! When they're too large for my small table saw (most are) if I rough down to size with jigsaw (don't have circular saw) could I use a router against a straight edge to do a final cut?

I presume I could cut by hand nice and close then finish with plane, this sounds good but beyond me, always end up with opposite high and low corners when planing an edge

Any suggestions?