SketchUp Guru

Established Member

I actually have a project to report on for a change.

Last weekend I started on a new steering wheel for my sailboat. (Funny, that boat was "finished" four years ago but I'm still making stuff for it. :huh I made the spoke blanks which I sent off to a friend who kindly volunteered to turn them for me. They are laminated up from cherry and hard maple.

I made the spoke blanks which I sent off to a friend who kindly volunteered to turn them for me. They are laminated up from cherry and hard maple.

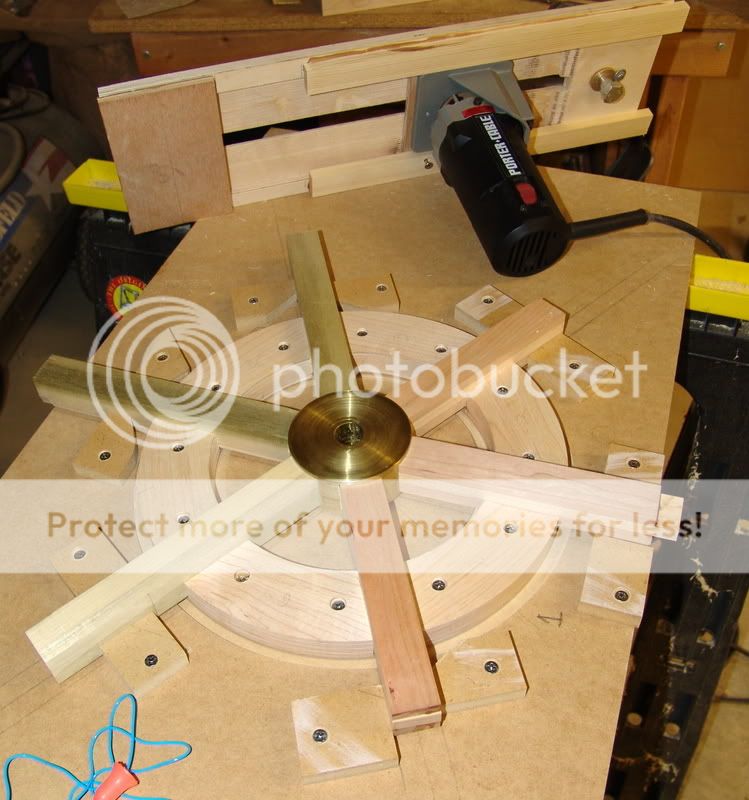

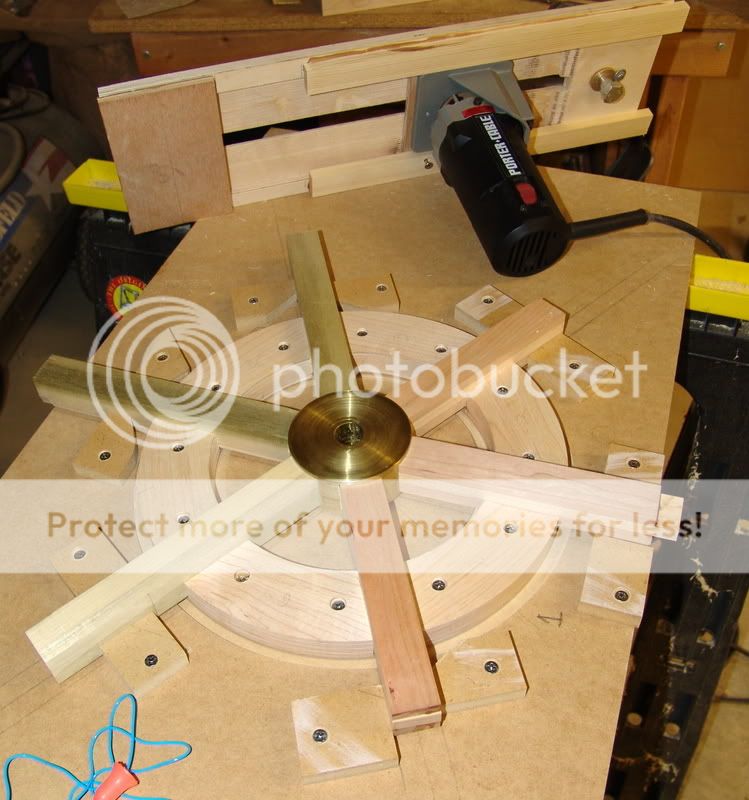

This weekend I made a trammel for my P-C trim router, milled the stock for the felloes, (the parts that form the rim of the wheel. They are called felloes on a wagon wheel, too.) and got the inner felloes cut to shape.

I had enough stock cut to the size of the spoke blanks to stand in for the ones my friend will be making so I could at least get this far.

The trammel was a bit of a challenge to work out. There aren't any extra screw holes on the bottom of the stock router base and there's not really that much vertical travel so the base couldn't be too thick. Since I have plenty of scraps I worked out what you can see in the pictures. I started by replacing the plastic base with one made from a scrap of 3/8" lauan ply I had left over from the boat. I used a piece of 12mm baltic birch ply for the trammel itself. I cut a channel in it for the new router base so it is a snug, slip fit. You can see some bits of pine on top that form the rails to hold the router down. Locking the router in place is a simple matter of drilling a hole and driving a screw through the rail, the base plate and the trammel. Not sophisticated but it works.

The next step is to make the two outer felloes rings and then I need to get the real spokes in place so they can be milled to receive those out felloes.

Thanks for looking.

Last weekend I started on a new steering wheel for my sailboat. (Funny, that boat was "finished" four years ago but I'm still making stuff for it. :huh

This weekend I made a trammel for my P-C trim router, milled the stock for the felloes, (the parts that form the rim of the wheel. They are called felloes on a wagon wheel, too.) and got the inner felloes cut to shape.

I had enough stock cut to the size of the spoke blanks to stand in for the ones my friend will be making so I could at least get this far.

The trammel was a bit of a challenge to work out. There aren't any extra screw holes on the bottom of the stock router base and there's not really that much vertical travel so the base couldn't be too thick. Since I have plenty of scraps I worked out what you can see in the pictures. I started by replacing the plastic base with one made from a scrap of 3/8" lauan ply I had left over from the boat. I used a piece of 12mm baltic birch ply for the trammel itself. I cut a channel in it for the new router base so it is a snug, slip fit. You can see some bits of pine on top that form the rails to hold the router down. Locking the router in place is a simple matter of drilling a hole and driving a screw through the rail, the base plate and the trammel. Not sophisticated but it works.

The next step is to make the two outer felloes rings and then I need to get the real spokes in place so they can be milled to receive those out felloes.

Thanks for looking.