This is a follow-up to my post of 14th May (see https://www.ukworkshop.co.uk/forums/352- ... 41714.html )

Recap: E-bay purchase, which was delivered in a bit of a state.

1. Negotiated £80 refund from seller.

2. Bought a complete set of guides form A.L.T. Saws (c. £100 ) (' ')

')

3. Took most things apart and re-assembled cast table with shims to true up as far as possible

4. Removed the GEC 750W 3000rpm three-phase motor and replaced with an almost-new Brook Hanson 1.2kW 750rpm slugger which I happened to have on the shelf....

This is not a trivial mod: the slower motor needed a 280mm pulley to maintain the blade speed, and the centre needed lowering c. 50mm to allow clearance with the lower-wheel pulley (itself 250mm). Plus of course a new longer belt. And a taper-lock bush.

Rear view:

5. The front fence rail was a bit worn, so I drilled & tapped new fixings so it could be replaced "upside-down"

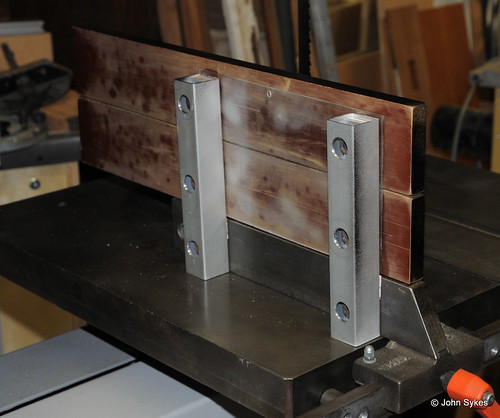

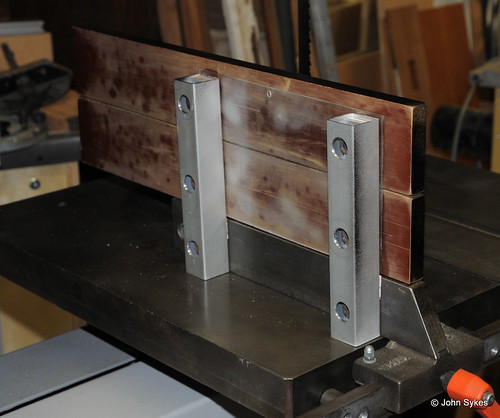

6. Added a heath-robinson fence-extension to allow more accurate deep re-sawing (fabricated from 15mm Tufnol sheet, supported by 1" square ali tube with ali bar inside).

7. Bought a new 3tpi x 5/8 fastcut blade from Ian at Tuff saws.

The motor is driven from an ABB inverter, so it can be soft-started and electronically-braked.

First trial cuts are on a small 4" chunk of cherry, sawn into 1/2" slices.

Having never owned/used a band-saw before, I'm so impressed by the thin kerf (1mm compared to 3.5mm on the circular saw).

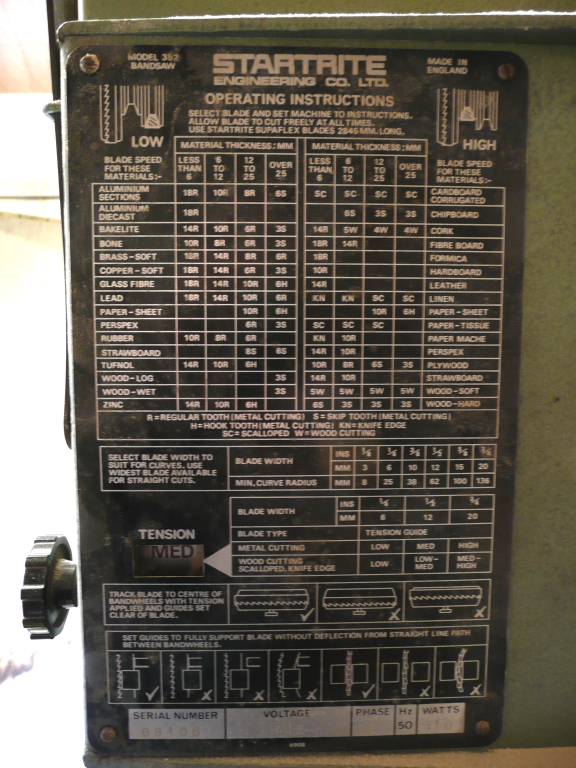

If anyone has any information on optimum blade-speeds for different blades/timbers. I'd very much appreciate some guidance. The original Startrite options were 4000ft/min or 1800ft/min: there's quite a gap between. With the inverter I can of course select any arbitrary speed.

John

Recap: E-bay purchase, which was delivered in a bit of a state.

1. Negotiated £80 refund from seller.

2. Bought a complete set of guides form A.L.T. Saws (c. £100 ) ('

3. Took most things apart and re-assembled cast table with shims to true up as far as possible

4. Removed the GEC 750W 3000rpm three-phase motor and replaced with an almost-new Brook Hanson 1.2kW 750rpm slugger which I happened to have on the shelf....

This is not a trivial mod: the slower motor needed a 280mm pulley to maintain the blade speed, and the centre needed lowering c. 50mm to allow clearance with the lower-wheel pulley (itself 250mm). Plus of course a new longer belt. And a taper-lock bush.

Rear view:

5. The front fence rail was a bit worn, so I drilled & tapped new fixings so it could be replaced "upside-down"

6. Added a heath-robinson fence-extension to allow more accurate deep re-sawing (fabricated from 15mm Tufnol sheet, supported by 1" square ali tube with ali bar inside).

7. Bought a new 3tpi x 5/8 fastcut blade from Ian at Tuff saws.

The motor is driven from an ABB inverter, so it can be soft-started and electronically-braked.

First trial cuts are on a small 4" chunk of cherry, sawn into 1/2" slices.

Having never owned/used a band-saw before, I'm so impressed by the thin kerf (1mm compared to 3.5mm on the circular saw).

If anyone has any information on optimum blade-speeds for different blades/timbers. I'd very much appreciate some guidance. The original Startrite options were 4000ft/min or 1800ft/min: there's quite a gap between. With the inverter I can of course select any arbitrary speed.

John