RogerS

Established Member

Starting to make some casement windows. I'm using the No.65 traditional window cutter from Axminster and this moulds the profile and rebate at the same time. It also has a scribing cutter (No.66) and you can see it mounted here

apologies for the breakout

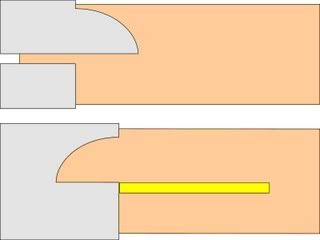

So far so good. But I think that the scribing cutter actually needs a bit more added to it as when you offer the rail up to the stile like so

you can see a shoulder left behind (arrowed). I can't see an easy way to remove it.

I can bandsaw down the side of the tenon but can't work out how to cut the bottom of the groove square. Note that it also has to be a groove to accomodate the slight shoulder.

A grooving cutter for my spindle moulder perhaps?

If the cutter had a bit extra on top then there wouldn't be a problem. Seems to me a lot of faffing about is needed.

Jason has given me an alternative approach using mitres and forgetting about scribing with the spindle moulder but I'd like to know if there is any obvious solution to my problem.

Many thanks

apologies for the breakout

So far so good. But I think that the scribing cutter actually needs a bit more added to it as when you offer the rail up to the stile like so

you can see a shoulder left behind (arrowed). I can't see an easy way to remove it.

I can bandsaw down the side of the tenon but can't work out how to cut the bottom of the groove square. Note that it also has to be a groove to accomodate the slight shoulder.

A grooving cutter for my spindle moulder perhaps?

If the cutter had a bit extra on top then there wouldn't be a problem. Seems to me a lot of faffing about is needed.

Jason has given me an alternative approach using mitres and forgetting about scribing with the spindle moulder but I'd like to know if there is any obvious solution to my problem.

Many thanks