Hi,

We recently got a new combination machine from the factory and it has angled snipe front and back and drags to one side in and out of the thicknesser. Had three visits from the company to try and find/fix the issue but no luck yet. They have replaced the in feed roller as he thought it might be cupped. Although I did think it would be tricky to make a cupped roller in error.

The blades are helix. Roller pressures and heights have been adjusted for hours but still the same issue. Bed is totally grease/dirt/rust free.

Slimmer pieces of wood work fine but wider widths 200mm+ really show it up. Have tried oak and maple as that is what we mainly use and both show up.

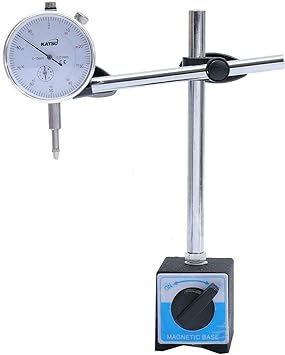

My question is the bed has a slight concave cup in the width by around .15 to .2 mm over 410mm would this be enough to cause these issues? They are thinking this wouldn’t be enough as it’s within their tolerances but I can’t think what else it could be.

We recently got a new combination machine from the factory and it has angled snipe front and back and drags to one side in and out of the thicknesser. Had three visits from the company to try and find/fix the issue but no luck yet. They have replaced the in feed roller as he thought it might be cupped. Although I did think it would be tricky to make a cupped roller in error.

The blades are helix. Roller pressures and heights have been adjusted for hours but still the same issue. Bed is totally grease/dirt/rust free.

Slimmer pieces of wood work fine but wider widths 200mm+ really show it up. Have tried oak and maple as that is what we mainly use and both show up.

My question is the bed has a slight concave cup in the width by around .15 to .2 mm over 410mm would this be enough to cause these issues? They are thinking this wouldn’t be enough as it’s within their tolerances but I can’t think what else it could be.