Honestly it has mostly been used as a 250kg workbench more than a table saw thus far

The fence that mine has has a bow in it which doesn't help and as yet I've still not found confidence that I'll get the results from it that I want, so I'm less inclined to use it. I WANT to use it, but also have limited time to dedicate to faffing around with it.

We're I flush with money then I'd more likely head toward something like the Laguna F3 or similar.

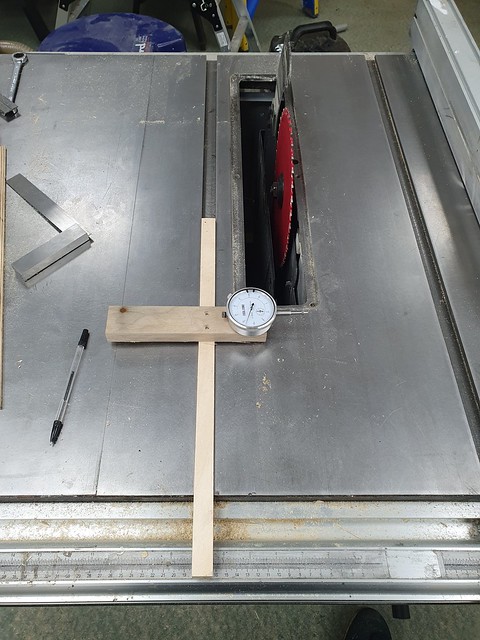

My main issues with the saw design (rather than my own versions issues) are that the blade is slung from the table, not the cabinet. This makes getting the blade parallel to the mitre slots frankly a colossal pain in the backside. You need to clamber underneath, open the door, reach in and undo 3 of the 4 bolts holding the blade to the table, then go back to the top and try and adjust it, to then go under again to do it up so that you can check it again to see that it moved a fraction. Repeat.

I'm not a fan of fences that grip both front and back.

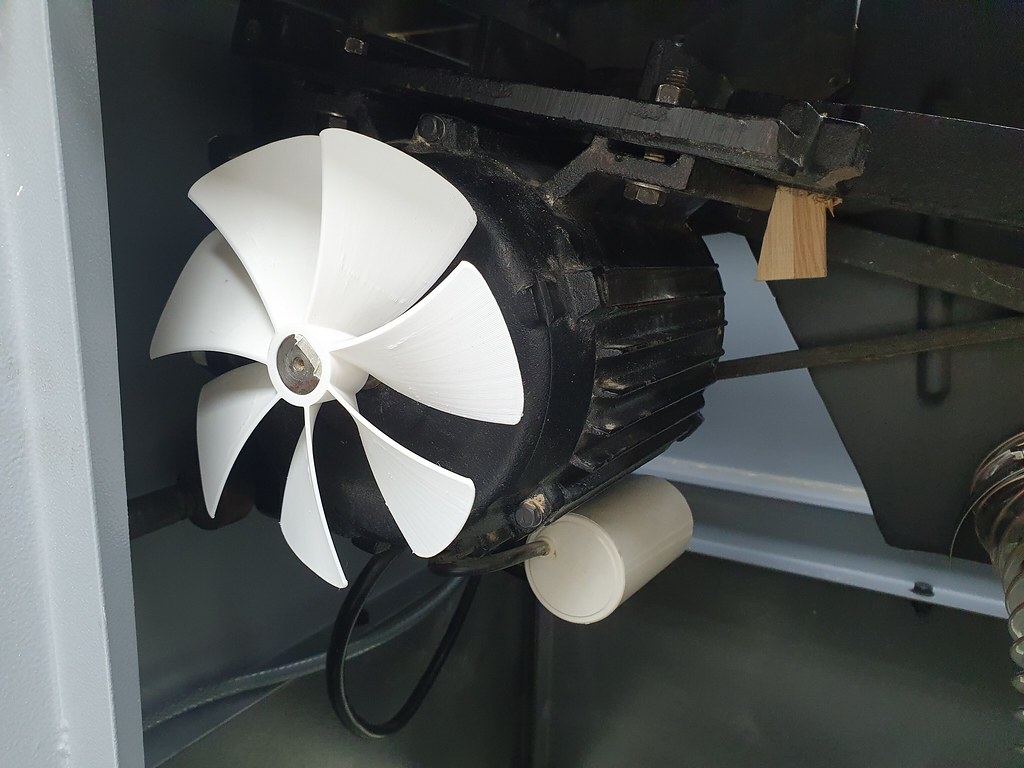

On top of that, the saw has had revisions that the parts diagrams do not reflect which means I was unable to replace a damaged part, having to find another creative solution so motor tensioning.

Getting it running to be happy with it is on the list. I'm currently working on a couple of other workshop projects before I get to that (again).