Picked this one up again yesterday but, with the Word Cup now under-way, I'm afraid to say that my progress has been "interrupted" somewhat...

I can't say it's been entirely worth it, either- the quality of this first week's games, overall, hasn't been that impressive - I'd have been better off in the workshop, most of the time.

Tenons on the top rails needed to be mitred so they didn't foul each other inside the legs:

After which, I was ready for my first dry-assembly:

[

Note - I hadn't shaped the stretchers or the front and back top rails at this point.]

As I was lining up this shot, there was this niggling thought in the back of my mind that

maybe Chris Knight was right... Perhaps these components are a little bit on the 'chunky' side... Looking at this photo now though, I'm not as concerned. I think we'll have a better idea once the top goes on and it's sat next to the finished chair.

To get the correct length and angles for the tenon shoulders on the slats, I used a tried-and-tested method that work well with the chair - two scraps of MDF, taped together. This allows me to transfer the information directly on to the timber. Hopefully, you can see how it works:

With those lines knifed on to the blanks, I could begin shaping. It took a good couple of hours in all - marking out, shaping, marking the shoulders, cutting the tenons, fitting and then sanding through the grits, ready for finishing - a very

un-enjoyable process!! :roll:

While a disc sander does a good job with convex curves, even with a fine-grit disc, you're going to end up with scratchers running perpendicular to the grain. They took some time to remove by hand, as I didn't feel I could use any form of power tool to do it for me, without affecting the curve. It's at times like this that I wonder whether a horizontal

linisher would help... Then again, perhaps I should give the Mike Garnham approach another try - fixing a portable belt sander on its side!!

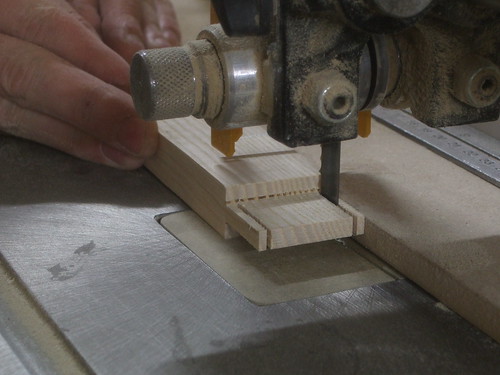

Trimming the tenons to width:

So, I spent the last few hours of yesterday hand-sanding :roll: all the other components, ready for a first coat of oil this morning. I would've put the oil on last night but, after all that work preparing each surface, I didn't have enough energy (plus, I wanted to see Italy struggle against Paraguay, apparently...

).

That first coat of Osmo Polyx (matt) went on this morning.

I don't like doing this first thing in the day because it means I have even less space to work in and I have to be cautious enough note to cover it all in fine dust! Not that I worry too much about first coats, anyway!

Over the weekend, I'd begun having a general tidy up and boxing up offcuts to give away as firewood on Freecycle so, I carried on and finished that off - ending up with three boxes, full :shock:.

After lunch, I decided the oil was "dry enough" (although, it was still a little sticky) so, I got things ready for the first stage of the glue up.

I just used bog standard PVA to glue the slats in, with the legs fitted dry to help keep things aligned correctly and square. I could've glued the legs on at the same time but, I don't like having clamps on, sticking out everywhere. I then spent most of the rest of the afternoon fiddling around with my planer (the

off buttons keep falling off inside!! :shock: And, it needed a bit of a clean.).

When I get back tomorrow afternoon, I'll make a start on the top. Once I've taken the dog for a walk this evening, I may have a go at gluing the legs on - it all depends on who's playing tonight and whether or not it's on ITV!!