Jacob

What goes around comes around.

Yebbut you wouldn't use a 6 or 7 on 1/4" stuff anyway. Still less if you had a 1/8" dip in the bench top - you'd probably plane out the dip first - but just to normal tolerances for any table top i.e. to seen to be "flat" by eye.bugbear":20vdjs80 said:Jacob":20vdjs80 said:Yes obviously a flat surface helps in general, but talk of "reference surfaces" is pseudo science. Even "fine workpieces thin enough to flex" don't need to be "flat", as they will flex and will be pulled into shape by the construction process whatever it is.

Not sure what you mean by pseudo science. That's normally applied to homeopathy and dowsing.

This is simple mechanics.

It's not straightness in the workpiece that causes the main trouble.

It's thickness.

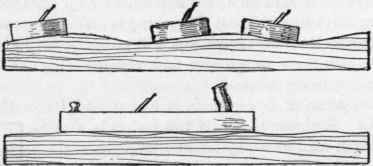

Consider trying to plane something down to 1/4" on a bench with a 1/8" concavity in length...

If the bench were flat, and the ends were 1/4" thick, and a #6 or #7 were used, the middle of the work would be 1/4", or near enough for a practical man.

But a 1/8" concavity in the bench would result in a workpiece 50% too thick in the middle.

Timber framers probably don't know this!

BugBear

There is a lot of "pseudo engineering" talked about in woodwork as we all know. "Flatness" features to a large extent, along with bevel mania. A work bench just needs to be "flat" like any other work surface and isn't itself a "reference surface" for flatness.