Hello all

I've been sharpening an old plane blade this weekend using an eclipse style hone guide.

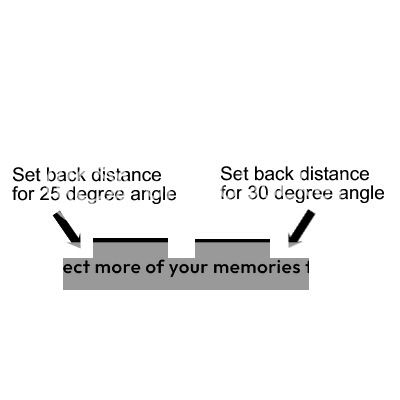

I've set the blade projection for a primary bevel of 30 degrees. How much difference should there be for the micro bevel? If I decrease the projection of the blade from the honing guide by a couple of mm will that be sufficient?

Thanks for any advice.

Stewart

I've been sharpening an old plane blade this weekend using an eclipse style hone guide.

I've set the blade projection for a primary bevel of 30 degrees. How much difference should there be for the micro bevel? If I decrease the projection of the blade from the honing guide by a couple of mm will that be sufficient?

Thanks for any advice.

Stewart