rob.

Established Member

I have a small space that I can work in and I would like to restore a couple of antique chests of drawers.

The chests have the usual problems of missing **** beading and worn drawer runners. There are also one or two loose joints to glue.

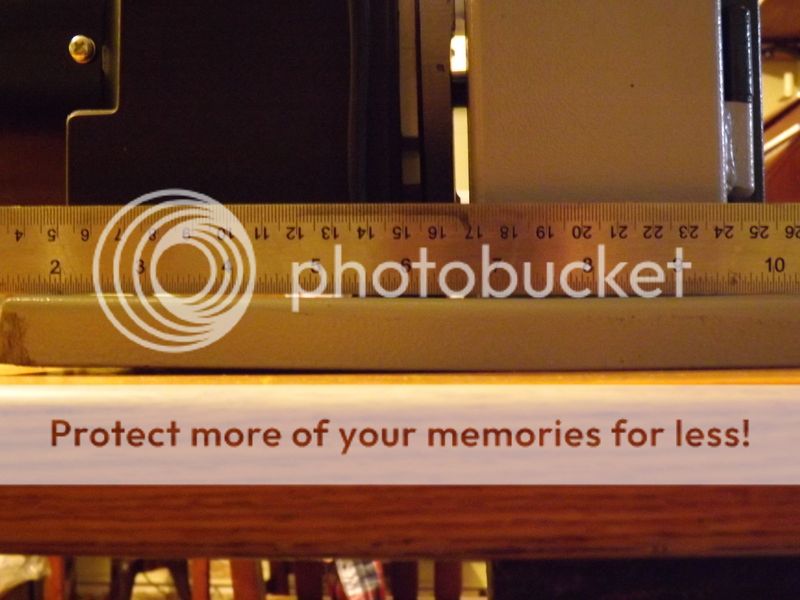

To cut the beading and runners I'm thinking a table saw might be best? However I have read that budget saws are not accurate and I don't think spending a small fortune on a decent one is really worth it for what I will be using it for.

I do however live close to an antiques auction house and can see myself buying a few furniture projects in the not too distant future.

So, back to saws, what do you guys think? Are budget saws any good? Would I be better off cutting by hand?

The chests have the usual problems of missing **** beading and worn drawer runners. There are also one or two loose joints to glue.

To cut the beading and runners I'm thinking a table saw might be best? However I have read that budget saws are not accurate and I don't think spending a small fortune on a decent one is really worth it for what I will be using it for.

I do however live close to an antiques auction house and can see myself buying a few furniture projects in the not too distant future.

So, back to saws, what do you guys think? Are budget saws any good? Would I be better off cutting by hand?