guineafowl21":3smq3k6y said:

Curse you! I was all set up to buy a simple router table...

Glad I could help :lol:

guineafowl21":3smq3k6y said:

I’ve gone and bought the Charnwood W030P2 package, justifying it as a router table, spindle moulder, tenoner, etc.

I didn’t take much persuading, being slightly unimpressed with the router table offerings. Either a make-your-own expensive kit, with no lift, or a crappy benchtop unit, or a hideously overpriced table with no router or lift.

That looks like a pretty comprehensive deal with everything included, interesting design too that you turn the fence around to work on the backside with more table depth and without the sliding table in the way. The router spindle should also come in handy but I doubt you'll get excellent results with bits smaller than 3" or so in diameter because the top speed of the machine is only 8000RPM. It should serve it's purpose well and will definitely be much better than most router tables, there isn't much if anything you can do with a router table that you couldn't do better and quicker with a spindle moulder.

guineafowl21":3smq3k6y said:

It comes with euro and rebate cutters. I’d quite like to make cabinet doors, like the old boy in the video, with a rail/stile cutter. Also raised panels. Would I need an additional special cutter for this, or could I get shaped knives for the euro cutter?

As far as what you'll need, for the doors themselves, you can pick up knives to fit in your Euro block for doing both the profile and scribe from various suppliers like Whitehill, CMT or Wealden, links below.

https://www.whitehill-tools.com/profile-cutters/kitchen-door-profiles/

https://www.scosarg.com/tooling/spindle-moulder-cutters/euro-cutters-40mm?p=3

https://www.wealdentool.com/acatalog/Knives_40_x_4_96.html

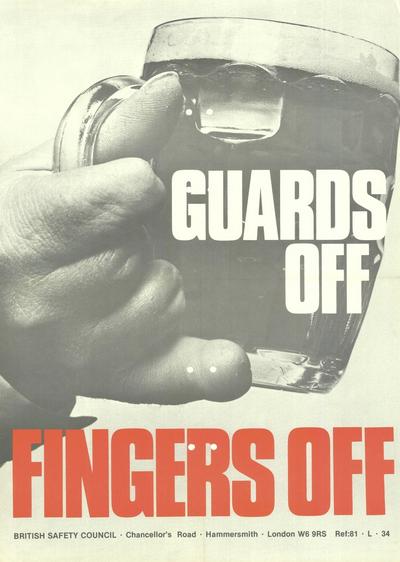

When buying knives you'll also need to buy the corresponding limiters, you

can run the block without the limiters and with blanks in their place but this means they can, in theory, take a full-depth cut in a single rotation which will cause severe kickback. It also means if your hand comes into contact with the spinning blades it will pull your whole hand into the cutter in a split second because it will want to take massive bites rather than the ~1mm per rotation limitation which will allow you to withdraw your hand if you come into contact, it all happens in a fraction of a second.

guineafowl21":3smq3k6y said:

Recommendations for a suitable book would also be appreciated - this looks like a versatile machine that requires study to get full use.

You're very correct that about requiring study to get full use out of the machine, I ignored the theory side of things largely when I started out in my career but when I started reading some old books on the machines it massively expanded my understanding and appreciation of how everything works plus they can give some very useful information you just won't find anywhere else. I think it's amazing how much information has been lost over the years as it seems the machinists from before the 70s would be far superior compared with most now even with modern equipment. I can recommend Eric Stephenson's "Spindle Moulder Handbook" as a modern textbook on the subject that's pretty up to date with modern safety standards whilst also giving very good information on the actual use of the machine. Another one worth picking up despite being more of a general machining book is Nigel Voisey's "Wood Machining, a Complete Guide to Effective and Safe Working Practices". You can pick up both books fairly inexpensively second-hand from various places. There are some older books which I think are excellent for reference but the information is very outdated and not really suitable for beginners to the machine because of some seriously questionable practices.

If you ever feel unsure about something, please ask here. They're an excellent machine but they're to be respected and not be trifled with, just like any other machine really.