motownmartin

Established Member

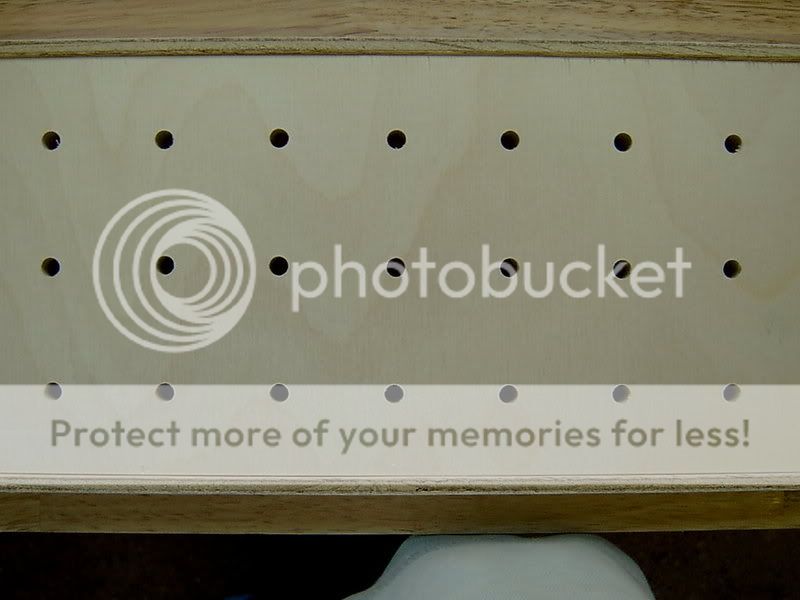

I managed to get in the workshop for a couple of hours this morning and assembled most of the carcase.

The plans called for biscuits to join the internal boards to the back but I wasn't sure how to get it accurate enough, in the end I opted for screws and glue.

If anyone could explain how to do this I would be grateful, although it's too late to do it on this job.

Some of the boards were slightly twisted but it seemed ok once I got the clamps on, the squareness was 2mm out across diagonal at the front, I was fairly happy with that.

The next Job is the drawers and I shall admit to being a little nervous, they seem to be just glued, I think I need some help with them ](*,) (hammer) #-o [-o<

The job up to date

The plans called for biscuits to join the internal boards to the back but I wasn't sure how to get it accurate enough, in the end I opted for screws and glue.

If anyone could explain how to do this I would be grateful, although it's too late to do it on this job.

Some of the boards were slightly twisted but it seemed ok once I got the clamps on, the squareness was 2mm out across diagonal at the front, I was fairly happy with that.

The next Job is the drawers and I shall admit to being a little nervous, they seem to be just glued, I think I need some help with them ](*,) (hammer) #-o [-o<

The job up to date