minilathe22

Established Member

Hi there

I am currently turning some large bowls from an apple tree and have recently moved house. Previously, the lathe was bolted to the concrete floor through the three holes in the base, with some cork between the floor and lathe to reduce vibration. This worked very well, however I was prevented from moving the lathe once its final location was chosen.

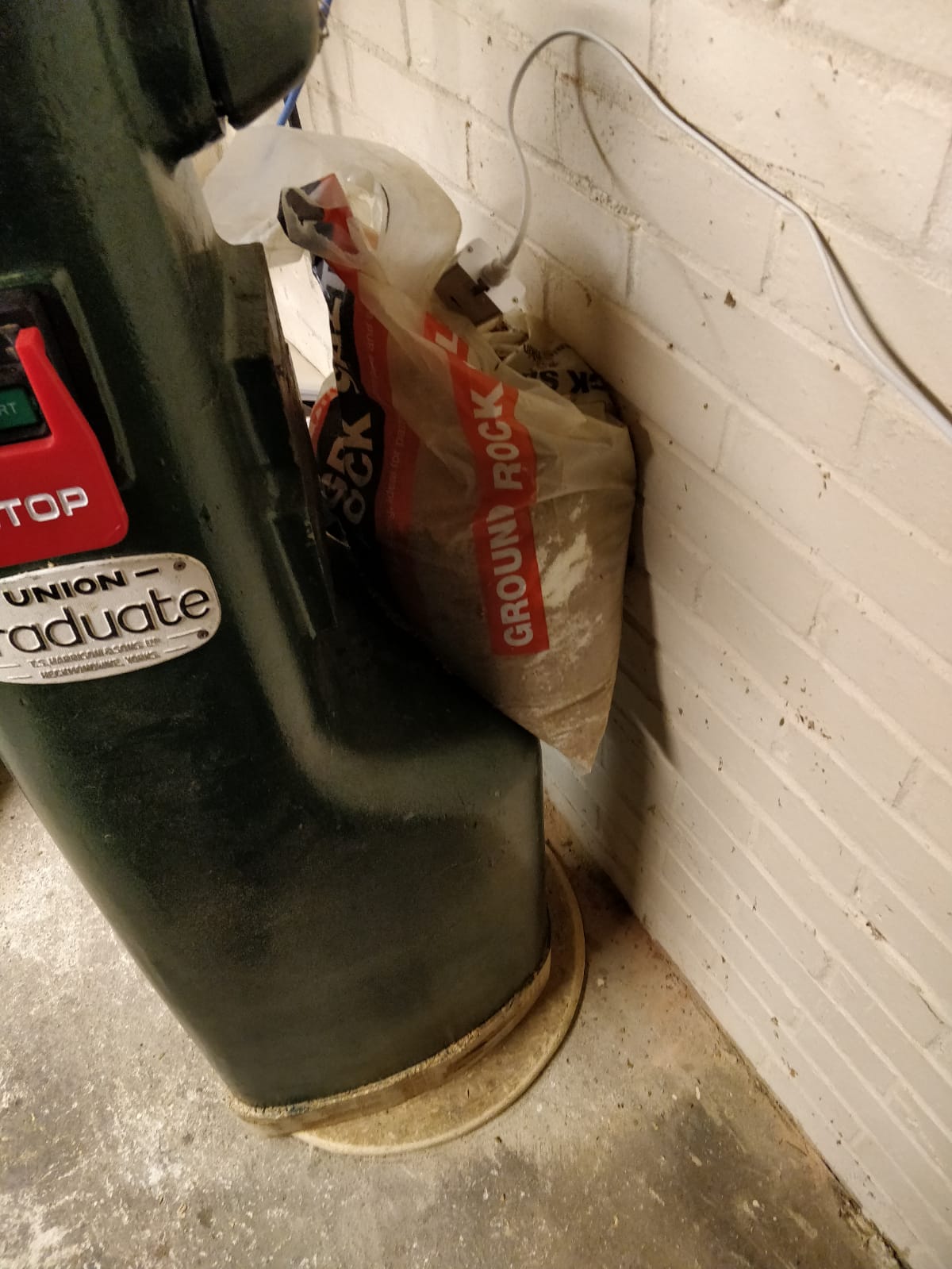

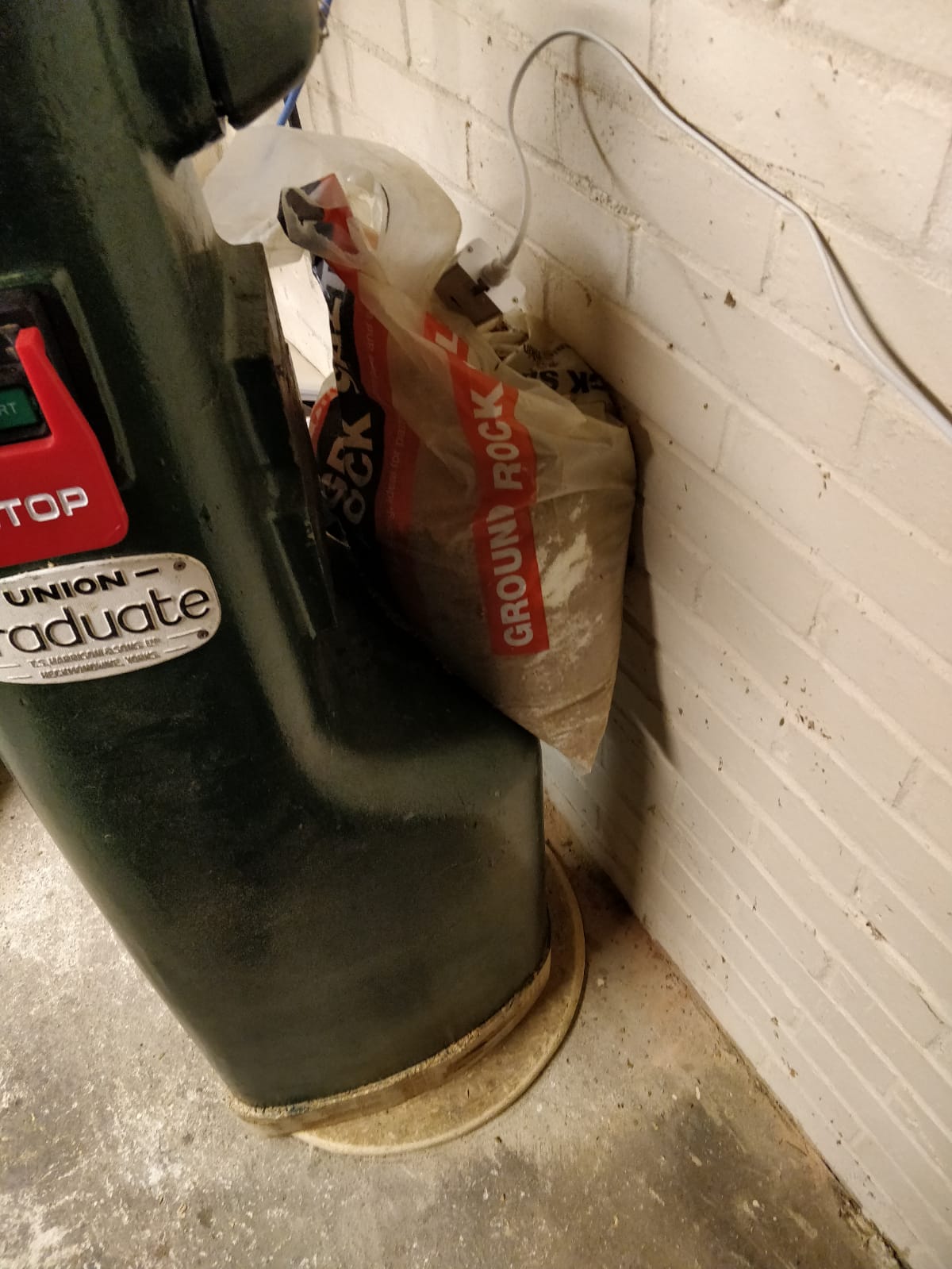

As I am left handed, I like to use the outboard side when I can, as its a much more natural position for me. I have rigged up a single centre bolt that runs through some pieces of chipboard. The top pieces are bolted to the lathe body. This allows me to slacken the bolt and rotate the lathe to have the outboard side facing outwards, or whatever position is convienent, or to rotate back to a position where I can add on the main bed for spindle turning.

Unfortunately the lathe wobbles when running, even with the bolt done up tight, I think the chipboard is flexing. I think I may need to make it again but out of welded sheet steel, or potentially use a wheel bearing and brake drum. Has anyone else made a smilar setup?

I am currently turning some large bowls from an apple tree and have recently moved house. Previously, the lathe was bolted to the concrete floor through the three holes in the base, with some cork between the floor and lathe to reduce vibration. This worked very well, however I was prevented from moving the lathe once its final location was chosen.

As I am left handed, I like to use the outboard side when I can, as its a much more natural position for me. I have rigged up a single centre bolt that runs through some pieces of chipboard. The top pieces are bolted to the lathe body. This allows me to slacken the bolt and rotate the lathe to have the outboard side facing outwards, or whatever position is convienent, or to rotate back to a position where I can add on the main bed for spindle turning.

Unfortunately the lathe wobbles when running, even with the bolt done up tight, I think the chipboard is flexing. I think I may need to make it again but out of welded sheet steel, or potentially use a wheel bearing and brake drum. Has anyone else made a smilar setup?