devonwoody

Established Member

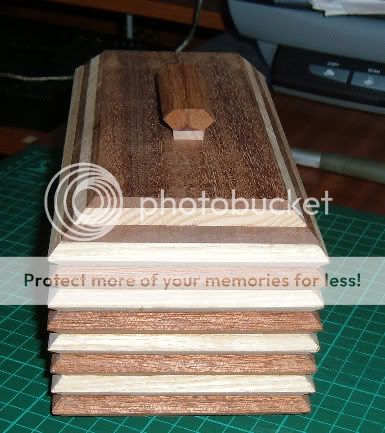

Started a new box yesterday and to me it is a new concept, I suppose somewhere there is a similar effect that has been created, they say there is nothing new under the sun.

Haven't got a plan or photograph I can show you of the design so it is a suck it and see for us all.

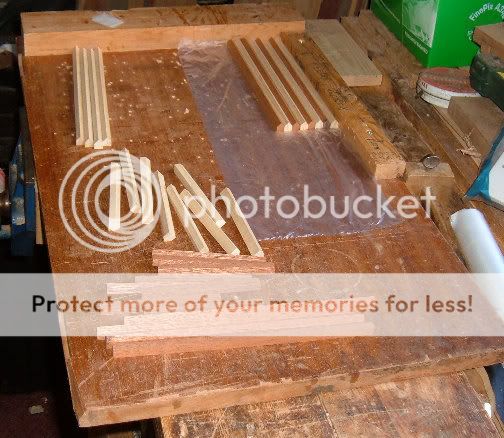

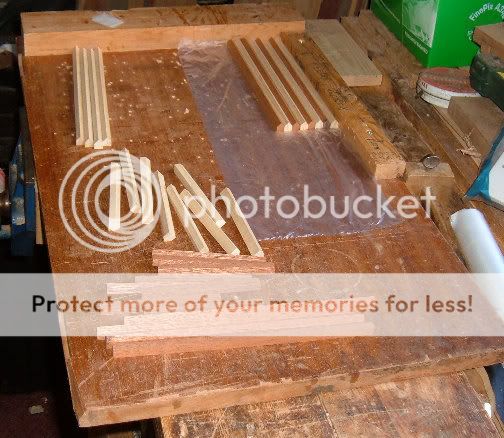

This first picture shows timber prepared from meranti and american ash, this was machined down to 12mmx10mm and one piece (short one) has been put on the router table and a triangular moulding put on one face. This trial moulding was a success so the remaining timber was also machined to the same dimensions.

All the strips were then reduced to finished sizes, and then are mounted on my flat board ready for gluing.

The first section has now been glued and weighted and held in position for glue to set.

The remaining carcass sections were brought inside for gluing owing to frosty weather conditions expected overnight.

Today Sunday I intend going back out to the workshop and putting a mitre joint to each end section. I am anticipating trouble at this point and might have to do some fiddling because I cannot expect mitres to meet exactly at their edges, but we will see!

Haven't got a plan or photograph I can show you of the design so it is a suck it and see for us all.

This first picture shows timber prepared from meranti and american ash, this was machined down to 12mmx10mm and one piece (short one) has been put on the router table and a triangular moulding put on one face. This trial moulding was a success so the remaining timber was also machined to the same dimensions.

All the strips were then reduced to finished sizes, and then are mounted on my flat board ready for gluing.

The first section has now been glued and weighted and held in position for glue to set.

The remaining carcass sections were brought inside for gluing owing to frosty weather conditions expected overnight.

Today Sunday I intend going back out to the workshop and putting a mitre joint to each end section. I am anticipating trouble at this point and might have to do some fiddling because I cannot expect mitres to meet exactly at their edges, but we will see!