Mcluma

Established Member

Replacing conveyor belt Performax 22-44 drum sander

Back in February I bought a drum sander from a forum member, who had actually never used it, but had it in stored for a long time,

How-ever as he stored it , the conveyor belt was left under tension, this caused some very heavy rippling, and also delamination of the paper from the rubber belt.

I have heard / read that this has happened to other people

So I bought a new conveyor belt and fitted it last night

Any tips on getting the tracking spot on

Here the new belt

Untitled by mcluma, on Flickr

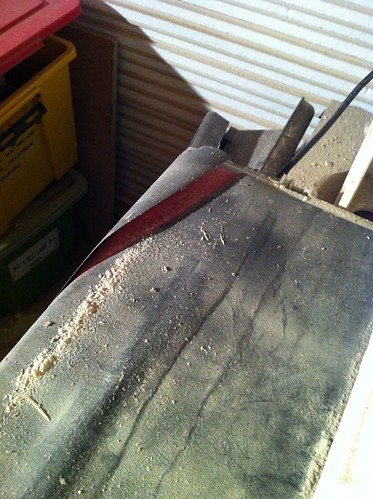

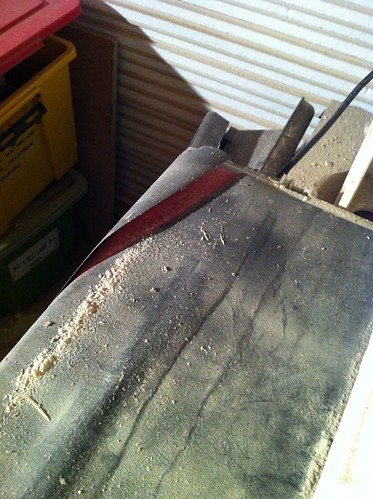

And here the old one – you can clearly see the rippling and delamination

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

Back in February I bought a drum sander from a forum member, who had actually never used it, but had it in stored for a long time,

How-ever as he stored it , the conveyor belt was left under tension, this caused some very heavy rippling, and also delamination of the paper from the rubber belt.

I have heard / read that this has happened to other people

So I bought a new conveyor belt and fitted it last night

Any tips on getting the tracking spot on

Here the new belt

Untitled by mcluma, on Flickr

And here the old one – you can clearly see the rippling and delamination

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr