Update time.

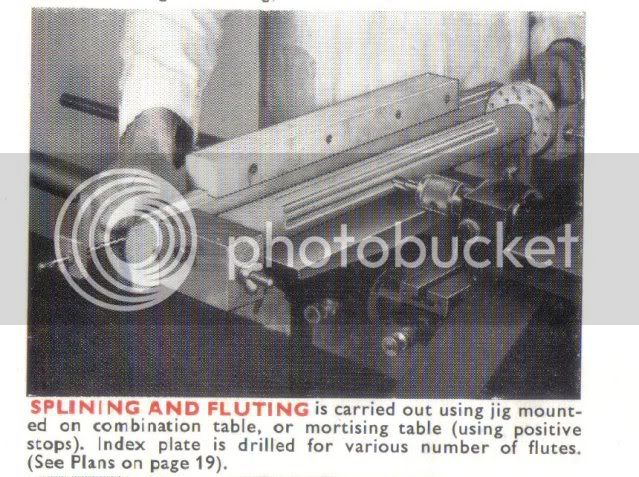

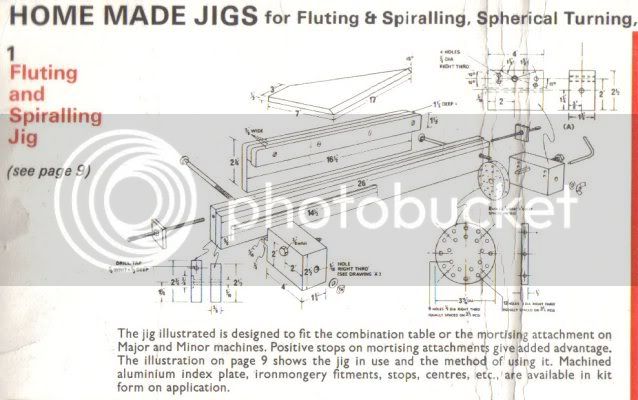

I've managed the flutes on all 4 legs, and reasonably happy with the result. I appreciate there are many jigs and ways of doing these, but I wanted to do them using a scratch, partly because of the control I would get. It's slow but you can progress the cut til you are happy with width and depth along the leg. There were 64 to do, and as with everything I got better (and quicker) as I progressed.

I made 2 discs (same dia) to screw into each end.

The upper one is indexed (16 lines) and a scrap is clamped to act as the mark.

The extended fence on the stock (trusty old Wickes marking gauge) runs along vice front.

I found the scratch was best in a fat ellipse profile rather than a pure circle. As the flute progresses down the leg it needs to get narrower and slightly shallower, but the ellipse seemed to approximate the shape better all along - and by tilting it you can adjust the flute profile (though that is getting very fussy maybe).

The scratch was a bit of bandsaw blade, hardened and honed after, using a ceramic stone.

i did find a quick re-hone made a big difference every leg - cutting far better.

The absence of support all along the leg induces chatter mid-way, so going slower and taking lighter cuts helps reduce that. The full-length jigs will eliminate that, but I was impatient and didn't fancy making the full length version with accurate tapers etc.

The end result needs some cleaning up... abrasives I expect.

One mistake was to turn the small birds-mouth at the top before fluting - the cutter can easily damage the edge of the turned detail. I had to re-turn taking a tiny amount off after fluting was finished.

Anyway, 4 legs fairly well matched... a hint of the handmade but I hope that may be a part of the charm.

Next , build them into a table with no top, then make and fit 2 half-drawers (half width, full depth) and 2 slide-out sides for taken pieces. Then make a top.

No rush on this one... more later.