Mr Ed

Established Member

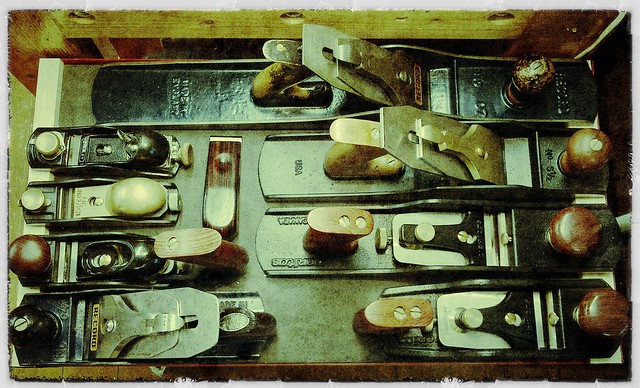

After months of unsuccessful eBay searching, I located a nice Record No.7 at Tony Murlands, which arrived today.

Turns out to be a war finish plane, which for something around 70 years old is in excellent condition.

I checked the sole with a straight edge and feeler gauges and there is a concavity of 0.015mm in the middle, which I don't think we'll worry about. So all in all a cracking plane, for £50.

Here's a little shot of it with the family

Cheers, Ed

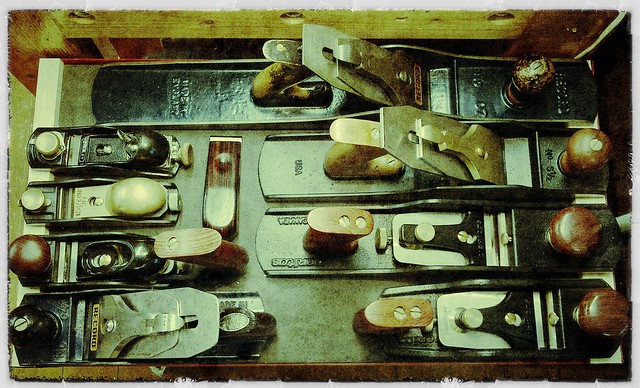

Turns out to be a war finish plane, which for something around 70 years old is in excellent condition.

I checked the sole with a straight edge and feeler gauges and there is a concavity of 0.015mm in the middle, which I don't think we'll worry about. So all in all a cracking plane, for £50.

Here's a little shot of it with the family

Cheers, Ed