DiscoStu

Established Member

Two related questions:

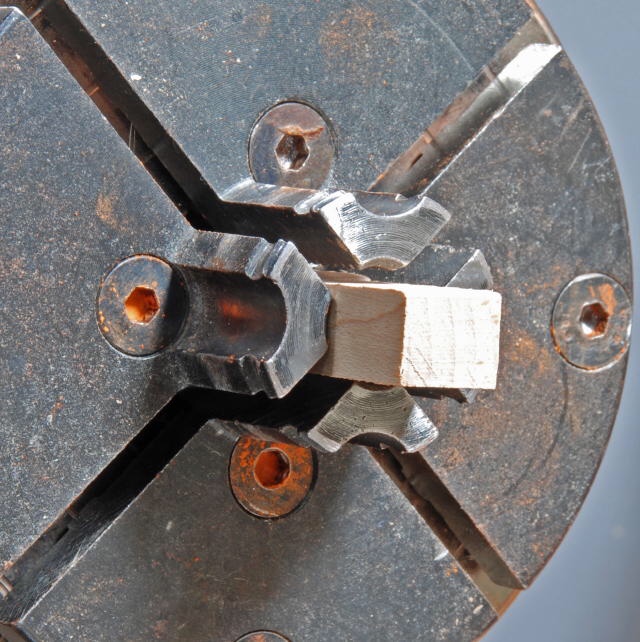

I've got an Axminster 100 chuck with C Jaws. I've got into pen turning and would like to get the Pen Jaws that Record make. Is there any way of using these on my Axi chuck?

Also I'm going to have a go a making a Salt and Pepper Mill, I'm thinking that I drill a 25mm hole from one end, turn it around and the pen jaws could be used inside the hole and be expanded to hold it whilst drilling the hole from the other end. Anyone know if that would work?

I've got an Axminster 100 chuck with C Jaws. I've got into pen turning and would like to get the Pen Jaws that Record make. Is there any way of using these on my Axi chuck?

Also I'm going to have a go a making a Salt and Pepper Mill, I'm thinking that I drill a 25mm hole from one end, turn it around and the pen jaws could be used inside the hole and be expanded to hold it whilst drilling the hole from the other end. Anyone know if that would work?