Hi,

The Scheppach Basa 3 that I ordered has arrived. I have put it together and am in the process of "fine tuning" it. (I have to say, the instruction manual is really not very clear). (Therefor,) I have a couple of questions:

1) In the manual, the counter pressure bearings (which are no real bearings) that absorb the feed pressure of the work piece are shown like this (the number 1 on the image):

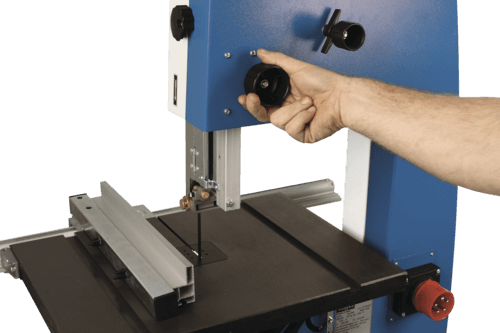

The feed pressure "bearing" underneath the table indeed is situated like that. However, the one that is above the table is on the other side, like this:

AND...you cannot push this circular black "bearing" against the back of the saw, because it the black disc is not big enough...it actually sits to the side of the saw...I can take it out completely (it is just a metal black disc on a metal stick...no spring or anything...I'm not sure how it works, even if the back of the saw was pushing against is).

Now, looking at a couple of youtube video concerning the Scheppach basa 3, they all seem to have -at least the upper - feed pressure "bearing" (the one above the table) on the right side, just as shown in the picture above. So, I'm not sure what to do. Should I position it the way it is positioned under the work table? Or is anything else going on..?

I'd really appreciate your advice on this.

Question 2) Then I have a question about the tension of the saw. The Basa 3 - as you know - comes fitted with a saw. This is a 1 cm broad saw. The tension coming from the factory/distributor was set to "1/2". It seems that on the small image (see underneath) the tension setting should be the same as "x", which is the broadness of the saw. That would mean that I would have to set it to "1" instead of "1/2". So, I think I'm misinterpreting things here.

What tension setting should be used for this 1cm broad saw? Is setting "1/2" indeed the right setting? (I'm also asking, because the saw cuts very wobbly, and does not cut in a straight line. And I did put the guiding rollers [#2 in the manual image, above] quite a bit closer to the saw than is shown in the first photograph that I attached).

Any ideas? Thanks!

The Scheppach Basa 3 that I ordered has arrived. I have put it together and am in the process of "fine tuning" it. (I have to say, the instruction manual is really not very clear). (Therefor,) I have a couple of questions:

1) In the manual, the counter pressure bearings (which are no real bearings) that absorb the feed pressure of the work piece are shown like this (the number 1 on the image):

The feed pressure "bearing" underneath the table indeed is situated like that. However, the one that is above the table is on the other side, like this:

AND...you cannot push this circular black "bearing" against the back of the saw, because it the black disc is not big enough...it actually sits to the side of the saw...I can take it out completely (it is just a metal black disc on a metal stick...no spring or anything...I'm not sure how it works, even if the back of the saw was pushing against is).

Now, looking at a couple of youtube video concerning the Scheppach basa 3, they all seem to have -at least the upper - feed pressure "bearing" (the one above the table) on the right side, just as shown in the picture above. So, I'm not sure what to do. Should I position it the way it is positioned under the work table? Or is anything else going on..?

I'd really appreciate your advice on this.

Question 2) Then I have a question about the tension of the saw. The Basa 3 - as you know - comes fitted with a saw. This is a 1 cm broad saw. The tension coming from the factory/distributor was set to "1/2". It seems that on the small image (see underneath) the tension setting should be the same as "x", which is the broadness of the saw. That would mean that I would have to set it to "1" instead of "1/2". So, I think I'm misinterpreting things here.

What tension setting should be used for this 1cm broad saw? Is setting "1/2" indeed the right setting? (I'm also asking, because the saw cuts very wobbly, and does not cut in a straight line. And I did put the guiding rollers [#2 in the manual image, above] quite a bit closer to the saw than is shown in the first photograph that I attached).

Any ideas? Thanks!