Well, after the advice offered here, I purchased the pump for £25 plus £9 courier. It’s a beast at 25kg. I bought the VFD and took the connector plate off the pump terminal housing. The terminals were connected along the top row in the star arrangement. Taking the links off and putting the as per diagram for delta mode I addded the UVW wires from the VFD.

set VFD parameters to 50Hz, 2 pole, 2850 revs, as lowara’s data sheet.

Powered VFD up, turned dial and Yey! Motor not only turned, but in the correct direction first time. It accelerates to full speed over four or five seconds and I’ve cut the deceleration time to two seconds. This means the startup current is not a massive load and the water will build pressure over those few seconds.

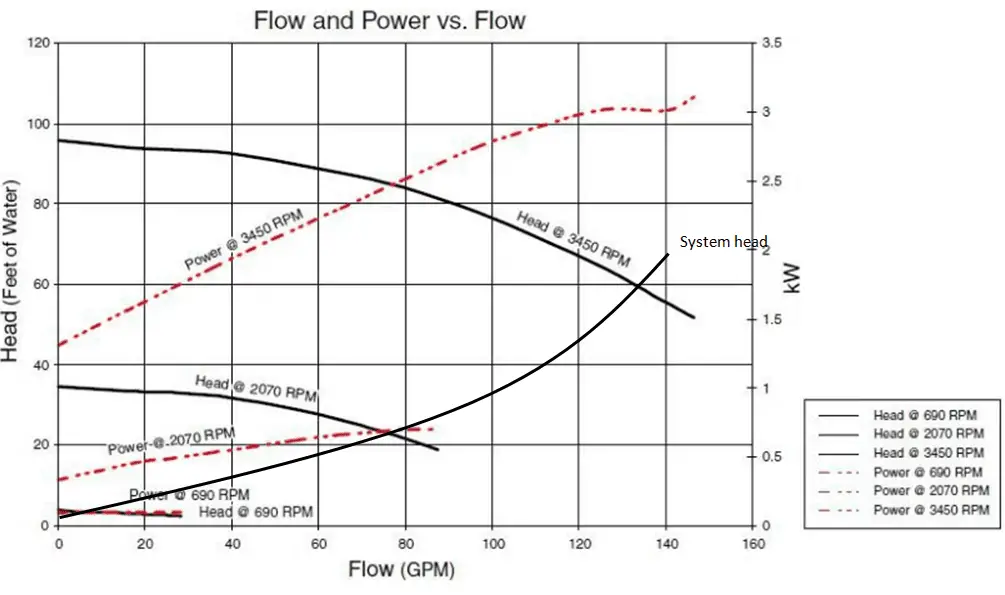

just got to install a 5000l tank and plumb it in to the travelling irrigation system. At least with this system I have the option to reduce flow by valve or motor speed if it delivers too much water. It’s rated at 210l/m I probably only need a little over a third of that. Not sure which way is the best to control flow to impact less on the motor or VFD if indeed it makes any difference to stress. The motor will need to be run for one hour at a time, perhaps twice a week in the dry weather, nothing in the wet.

Full speed at reduced flow, or reduced speed at full flow, which would you say is better?

Without this thread I wouldn’t have dared try this as a viable project, so thanks for all the replies and offers of help.

i believe the wiring diagram in the lid shows the motor at 230v single phase capable, but unsure what the other symbols mean on that diagram.

wiring diagram for single phase 230v?