You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problems turning first proper bowl - not round?

- Thread starter dadiy

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dadiy":qgra8m5a said:Interesting - I have a 1/2" bowl gouge but I assumed as its a lot smaller than the 3/4" roughing gouge that it was too small and weak for the job.

I have the Crown 'Axminster' Turning Tool Set which included both.

Its not the blade area thats the issue - its the tang ( the bit that goes into the handle ) - very narrow on a roughing gouge, whereas the tang on the bowl gouge ( and spindle gouges ) will be same dia as the blade area, as its just a single diameter bar !

See here

The roughing gouge don't have the strength to handle end grain, and when turning a bowl / other face work, you will encounter end grain twice in each revolution.

Bodrighy

Established Member

dadiy":1xx44ili said:Interesting - I have a 1/2" bowl gouge but I assumed as its a lot smaller than the 3/4" roughing gouge that it was too small and weak for the job.

I have the Crown 'Axminster' Turning Tool Set which included both.

You can use a bowl gouge on almost anything due to the way it is made. Look at the blade and shaft and you will see that it is solid bar drilled out whereas a spindle gouge, including a roughing gouge is forged to the shape. (Think I've got that the right way round :lol: ) A roughing gouge should ideally only be used as a spindle gouge. Any faceplate work should be roughed out with a bowl gouge.

Pete

Bodrighy":81ymtbrl said:You can use a bowl gouge on almost anything due to the way it is made. Look at the blade and shaft and you will see that it is solid bar drilled out whereas a spindle gouge, including a roughing gouge is forged to the shape.

Pete

hiya Pete,

I'm pretty sure my spindle gouges are milled bar's exactly the same as my bowl gouges. but I'll have to double check now !!!

Bodrighy

Established Member

loz":1jw26scw said:Bodrighy":1jw26scw said:You can use a bowl gouge on almost anything due to the way it is made. Look at the blade and shaft and you will see that it is solid bar drilled out whereas a spindle gouge, including a roughing gouge is forged to the shape.

Pete

hiya Pete,

I'm pretty sure my spindle gouges are milled bar's exactly the same as my bowl gouges. but I'll have to double check now !!!

You are probably right. Looking at this from the Tool Post site I am probably out of date

Pete

"Spindle gouges generally have shallower flutes than bowl gouges and are consequently, size for size, not as rigid as bowl gouges, reflecting the lower loads that they have imposed upon them. This shallow fluting allows good shaving clearance whilst the fingernail profile to which these tools are normally ground ensures that the wings are well back from the workpiece, allowing maximum maneuverability in use. Traditional gouges were forged from flat stock but most current designs are machined from bar stock which leads to a more rigid tool and allows small size versions to be produced for use in tight curves."[/i]

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

Paul.J

Established Member

You can use your bowl gouge to do the whole bowl.

As said the Spindle roughing gouge is to be used for spindle work only,not cross grain work.

As said the Spindle roughing gouge is to be used for spindle work only,not cross grain work.

Oh dear and ooppss ! guess who was showing an even more of a beginner than I how to use a roughing gouge at the turning club this very afternoon ..... to start off a bowl blank !!! :roll: :roll:

I will have to look this guy out and apply correction !

Thanks for that.

Rob

I will have to look this guy out and apply correction !

Thanks for that.

Rob

CHJ

Established Member

Being very PC about it I'd say at least before the first cut and again before the last one, and several times in between if the wood thinks it's boss.dadiy":wn3m9e4e said:...... How often do you guys sharpen?

Put it this way, if there is the slightest doubt that the tool needs sharpening it should have been done at least half a dozen cuts ago if pulled/torn grain is to be avoided.

dadiy

Established Member

- Joined

- 29 Mar 2010

- Messages

- 31

- Reaction score

- 0

So does anyone here have any experience of the crown 'axminster' turning tool set? I took the advice and went back with the bowl gouge which as stated has a large solid bar tang.

I found that the tool didnt cut so I gradually increased the angle and all that happened was the tool started to take chunks out of the surface, the next thing I knew half the bowl bounced off my head. OUCH

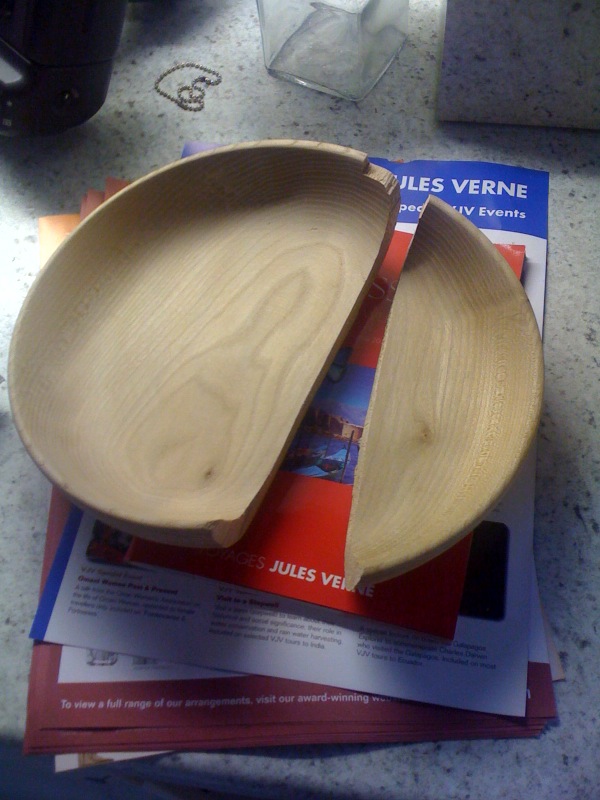

So Ive gone from

to

with a mild headache.

Ive never used this tool before so it should be sharp, but Ive read a few posts about tools not being sharpened properly when new?

I found that the tool didnt cut so I gradually increased the angle and all that happened was the tool started to take chunks out of the surface, the next thing I knew half the bowl bounced off my head. OUCH

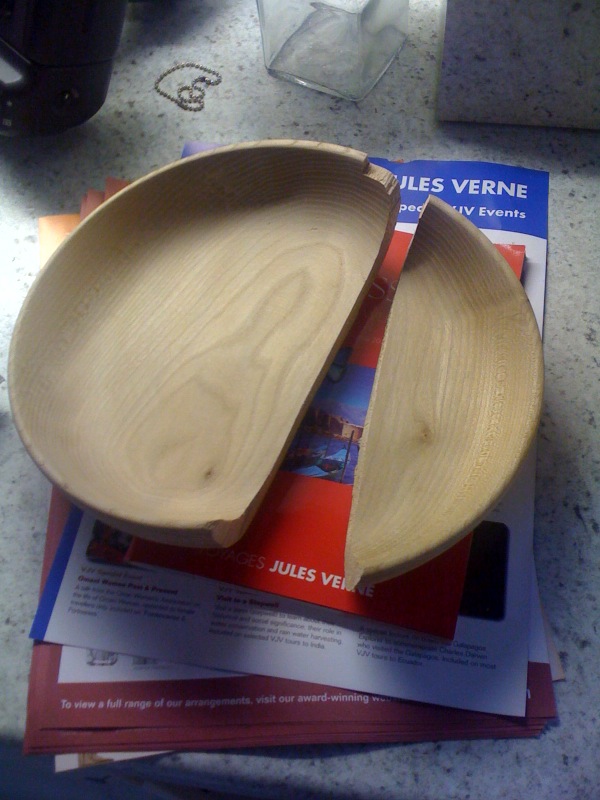

So Ive gone from

to

with a mild headache.

Ive never used this tool before so it should be sharp, but Ive read a few posts about tools not being sharpened properly when new?

Paul.J

Established Member

Thats a shame D,and hope you are ok,but i think i'd have been have how it was.

The ovaling must have happened as it dried out.

I have no experience with Crown tools but it sounds as if it/they do need a sharpen as they aren't always sharp straight out the box,nor in the case of the bowl gouge at the right angle grind to suit you.

On the plus side the bowl looks to be nicely turned and finished so the next one should be better.

The ovaling must have happened as it dried out.

I have no experience with Crown tools but it sounds as if it/they do need a sharpen as they aren't always sharp straight out the box,nor in the case of the bowl gouge at the right angle grind to suit you.

On the plus side the bowl looks to be nicely turned and finished so the next one should be better.

Ad de Crom

Established Member

I did read all the discussions, and I'm thinking the main problem is the oak itself. Have turned in the past lots of oak, and if oak is not completely dry, it always crack like crazy, and shows irregularities you don't like to see. At least this is my experience with oak.

Has oak in my woodstore since 2001 which is dry enough for using, so it takes many years before you safely can use this stuff.

Has oak in my woodstore since 2001 which is dry enough for using, so it takes many years before you safely can use this stuff.

Similar threads

- Replies

- 29

- Views

- 4K